P44 MiCOM 5th Generation

Line Distance Protection

The P44, part of the MiCOM P40 Agile 5th Generation family, is a line distance Protection that delivers high performance processing and a graphical HMI as standard and provides up to 9 zones of subcycle distance protection with both mho/quad characteristics and delta directional comparison (incremental) protection.

P44 MiCOM 5th Generation

Line Distance Protection

The P44, part of the MiCOM P40 Agile 5th Generation family, is a line distance Protection that delivers high performance processing and a graphical HMI as standard and provides up to 9 zones of subcycle distance protection with both mho/quad characteristics and delta directional comparison (incremental) protection.

Overview

Transmission and distribution systems are essential for the safe, sure routing of power from generation sources to consumers. However, exposed overhead lines transporting power are by nature sometimes vulnerable and prone to fault. In the case of a faulty circuit, the MiCOM range provides speedy protection to trip and isolate it, thereby preventing further damage.

Each relay model contains multiple main protection elements: distance, delta directional incremental protection and directional earth/ground fault unit protection (DEF). This permits simplified application and spares holdings, because the relay can be adopted as the standard protection platform.

The MiCOMho P44 is suitable for feeders controlled by a single circuit breaker and for complex installations where feeders are controlled by two circuit breakers such as ring bus/mesh corner formations and the breaker-and-a-half configurations.

Key Benefits

- Sub-cycle fault clearance from 0.7 to 1 cycle

- Simple set mode: The relay determines its own settings from protected line data

- Power swing blocking without the need for setting

- Integral teleprotection via a MODEM, fiber or MUX channel

- Fast CB failure resetting (< 3/4 cycle)

- Phase-preference tripping for cross-country earth faults in Petersen/isolated systems

- Multi-shot 1/3pole & 3pole autoreclosure with check synchronism - adaptive technology to detect fault arc extinction and accelerate the dead time or drive to lockout for persistent faults. Improves system stability whilst reducing OPEX.

Main Characteristics:

- Comprehensive communication options including IEC 61850 Edition 2

- IEC 61850 redundant Ethernet protocols - RSTP, PRP or HSR

- IEC 61850 9-2LE redundant PRP Process bus protocol

- Fast subcycle distance protection with quadrilateral or mho zones and setting free power swing detection

- InterMiCOM64 for transmitting digital signals (32) through teleprotection communication links

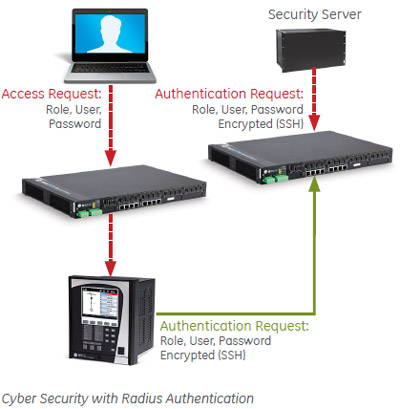

- Advanced Cybersecurity including AAA, Radius, RBAC, and Syslog

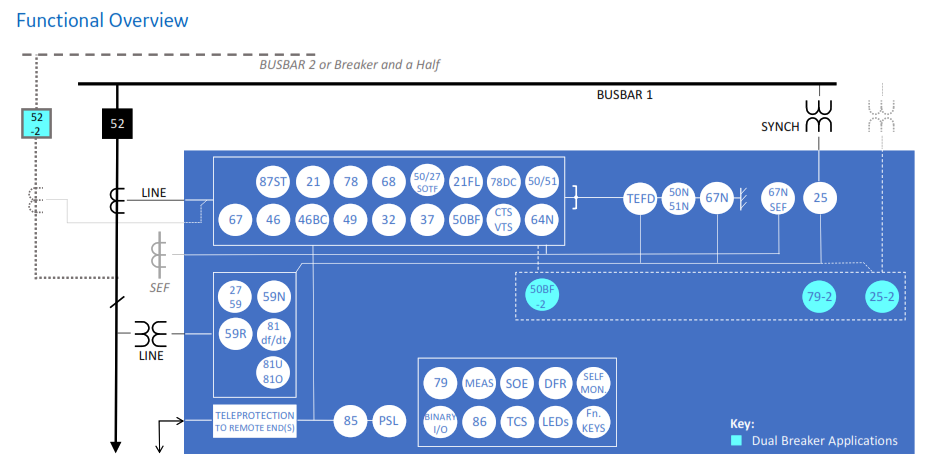

Functional Block Diagram

ANSI ® Device Numbers and Functions

| Device Number | Function |

|---|---|

| 25 | Check Synchronizing |

| 27 | Pand & Line Undervoltage |

| 37 | Undercurrent |

| 46 | Negative Sequence Overcurrent |

| 49 | Thermal Overload |

| 50 | Phase Definite Time Overcurrent |

| 51 | Phase Inverse-Time Overcurrent |

| 52 | Circuit Breaker Control |

| 59 | Phase & Line Overvoltage |

| 67 | Directional Phase Overcurrent |

| 68 | Power Swing Blocking |

| 78 | Out-of-Step Tripping |

| 78DC | Delta (Incremental) Protection |

| 79 | Autoreclose/Adaptative Autoreclose |

| Device Number | Function |

|---|---|

| 85 | InterMiCOM Teleprotection |

| 86 | Latching/Lockout Contacts |

| 21BL | Load Encroachment/Blinder |

| 21FL | Fault Locator |

| 21G | Ground Distance |

| 21P | Phase Distance |

| 46BC | Broken Conductor |

| 50/27 | Switch-on to Fault |

| 50BF | CB Failure |

| 50N | Earth Fault Definite Time Overcurrent |

| 50ST | Stub Bus Protection |

| 51N | Neutral/Ground IDMT Overcurrent |

| 59N | Neutral Voltage Displacement |

| 59R | Remote End Overvoltage |

| Device Number | Function |

|---|---|

| 64N | Restricted Earth Fault |

| 67N | Directional Neutral/Ground Overcurrent |

| 81df/dt | Rate of Change Frequency |

| 81O | Overfrequency |

| 81U | Underfrequency |

| CTS | CT Supervision |

| PSL | Programmable Logic |

| SEF | Sensitive Earth Fault |

| TEFD | Transient Earth Fault Detection |

| TCS | Trip Circuit Supervision |

| VTS | VT Supervision |

P44 MiCOMho 5th Generation

P44 MiCOMho Line Distance Protection Buy Now

MiCOM S1 Agile

Key benefits:

- Powerful, free of charge, PC toolsuite

- Optimum management of the installed base, structured as per the substation topology

- Intuitive and versatile interface with file management facilities

- Logical structure based on substation, voltage level and bay

- Version control and cross-checking facilities for IED settings

- Real-time measurement visualization – MiCOM S1 Agile extends to all MiCOM Agile IEDs - including P847 PMU and busbar schemes

Engineering Tool Suite

S1 Agile is the truly universal PC tool for MiCOM Agile relay, assemble all tools in a palette for simple entry, with intuitive navigation via fewer mouse-clicks. No-longer are separate tools required for redundant Ethernet configuration, phasor measurement unit commissioning, busbar scheme operational dashboards, programmable curve profiles or automatic disturbance record extraction – applications are embedded. MiCOM S1 Agile supports all existing MiCOM, K-Series and Modulex, including a utility for automatic conversion of setting files from previous generations of numerical relays like K-series and MiCOM P20 to the latest P40 Agile models.

To move to the future, with no loss of functionality, no loss of device support, and full compatibility with your installed base and system architecture – request a copy of S1 Agile with the contact form link below.

Key features in the MiCOM S1 family:

- GE Vernova’s integrated engineering tool that provides users with access to automation IED configuration and record data

- Integrated configuration and monitoring features

- Send and extract setting files

- Single Line Diagram creation with inbuilt editor

- Event and disturbance record extraction and analysis

MiCOM S1 Agile software request

To receive the MiCOM S1 Agile, please use our Contact form. This will also ensure that you are kept up-to-date with the latest enhancements, including updates and bug fixes.

Refurbishment Solutions

GE Vernova’s latest P44 MiCOMho 5th Generation transmission models offer a perfect functional match to our “mho” family of distance relays, from the heritage installed-base brands GEC Measurements, GEC Alsthom, GE VERNOVA and Areva. The subcycle pedigree is maintained, optimised and advanced:

SHNB Micromho and SHPM Quadramho Replacement:

- Full functional compatibility

LFZP Optimho and LFZR Replacement:

- Form, fit and functional compatibility – the P44 fits in the same panel or rack space

- The same S1 Agile software supports the new MiCOM relay and the legacy LFZR

LFDC Delta Directional Comparison Relay Replacement:

- Form, fit and functional compatibility – the P44 fits in the same panel or rack space

- Implements “delta” (incremental quantity) protection schemes along with distance zones

- Half-cycle protection response possible

MiCOMho P441/2/3/4/5/6 Relay Replacement:

- Form, fit and functional compatibility – the P44 fits in the same panel or rack space and offers the same features and Protection performance.

- The same S1 Agile software supports the new MiCOM relay and the legacy P443/5/6 and P441/2/3/4/5/6.

Pin-Pin Upgrade Methodology:

- Take the order code (CORTEC) of the older relay being removed, typically a blue case relay

- Translate to today\’s latest GE Vernova MiCOM model, adding Ethernet options if required

- Order the new P40 relay

- Extract settings and logic, use S1 Agile toolsuite to convert settings

- Detach the medium duty terminal blocks from old relay, leaving wiring attached / detach terminal blocks from the new.

- Carefully examine the terminal blocks to see that no physical damage has occurred since installation.

- Mount new relay. Old relay blocks fit straight onto the new relay - safer, less wiring to reconnect.

- It is recommended to apply rated current and voltage to the relay CT/VT inputs during secondary injection testing to check the continuity of the CT/VT terminal block connections to the relay.

- Download converted files

- Test, return circuit to service with only minutes of downtime

Recommended Products & services

MiCOM Agile P543, P544, P545 & P546

Line Differential and Distance Protection

Part of the MiCOM P40 platform, the Agile P543, P544, P545 & P546 range of transmission-class protection relays provide comprehensive line protection for differential, subcycle distance and directional earth fault applications, with 1/3 pole tripping. This range of products is ideal for HV, EHV and UHV applications on lines and cables of any length.

MiCOM Agile P543, P544, P545 & P546

Line Differential and Distance Protection

Part of the MiCOM P40 platform, the Agile P543, P544, P545 & P546 range of transmission-class protection relays provide comprehensive line protection for differential, subcycle distance and directional earth fault applications, with 1/3 pole tripping. This range of products is ideal for HV, EHV and UHV applications on lines and cables of any length.

What's New

Enhanced Ethernet board module with switchable Ethernet redundancy delivered in a single model.

It supports PRP, HSR and RSTP in one model, allowing a single P40 model to be used in any application requiring redundant Ethernet communications. The new module is designed to handle high density traffic in the IEC 61850-8-1 network, with time latency halved. Larger architecture digital substations can also be supported, with up to 50 nodes now possible in HSR rings.

Key Features & Benefits:

- Universal IRIG-B – Modulated and demodulated supported in the same model

- HSR Ring – Extended to 50 node support for larger substation architectures

- Fast performance, particularly in onerous applications such as where process bus GOOSE is used for tripping purposes

Overview

The MiCOM Agile P543, P544, P545 & P546 range of transmission-class protection relays provide high speed current differential unit protection. They are designed for overhead line and cable applications, interfacing readily with the longitudinal (end-end) communications channel between line terminals. The interface options support direct fiber optic or multiplexed digital links.

Each of the models offer resident subcycle distance protection to complement the powerful suite of main and backup protection. Full scheme, five-zone distance protection is adopted from the class-leading MiCOMho MiCOM Agile P443. The product line becomes the standard in all HV, EHV and UHV line protection applications, duplicated where dual redundant main protection is demanded. Set any combination of differential, distance, overcurrent and reclosing, depending on the site needs. One universal relay type instead of two or more discrete models means reduced spares holding, less training, and lower cost.

The MiCOM Agile P544 and P546 are suitable for the complex installation and feeders controlled by two circuit breakers such as breaker-and-a-half configurations with dual breaker autoreclose logic schemes with synchrocheck for both breakers.

Key benefits:

- A universal relay that reduces spare holding - apply as a current differential relay, a distance relay, or both

- Neutral differential boosts sensitivity of tripping for resistive earth faults, even for lines with heavy load-flow

- Transient biasing reduces CT knee point dimensioning by typically 25% compared to historical applications

- Differential protection adaptable to all different substation topologies: in-zone transformers and unequal line end CT ratios

Main characteristics:

- Comprehensive communication options including IEC 61850 Edition 1 and Edition 2

- IEC 61850 redundant Ethernet, supporting self healing ring, RSTP, dual homing, PRP or HSR

- Fast subcycle distance protection with quadrilateral or mho zones and setting free power swing detection

- InterMiCOM64 for transmitting digital signals through teleprotection communication links

ANSI ® Device Numbers and Functions

| Device Number | Function |

|---|---|

| 25 | Check Synchronising |

| 27 | Phase and Line Undervoltage |

| 37 | Undercurrent |

| 46 | Negative Sequence Overcurrent |

| 49 | Thermal Overload |

| 50 | Phase Definitive Time Overcurrent |

| 51 | Phase Inverse-Time Overcurrent |

| 52 | Circuit Breaker Control |

| 59 | Phase and Line Overvoltage |

| 67 | Directional Phase Overcurrent |

| 68 | Power Swing Blocking |

| 78 | Out-of-Step Tripping |

| 78DC | Delta (Incremental) Protection |

| 79 | Autoreclose |

| Device Number | Function |

|---|---|

| 85 | Teleprotection Channel Schemes |

| 86 | Latching/Lockout Contacts |

| 87L | Line Differentila -2 or 3 Ends |

| 87N | Neutral Differential |

| 87T | In-Zone Transformer Differential |

| 21BL | Load Encroachment/Blinder |

| 21FL | Fault Locator |

| 21G | Ground Distance |

| 21P | Phase Distance |

| 46BC | Broken Conductor |

| 50/27 | Switch-on to Fault |

| 50BF | CB Failure |

| 50N | Earht Fault Definite Time Overcurrent |

| 50ST | Stub Bus Protection |

| Device Number | Function |

|---|---|

| 51N | Neutral/Groud IDMT Overcurrent |

| 59N | Neutral Voltage Displacement |

| 59R | Remote End Overvoltage |

| 64N | Restricted Earth Fault |

| 67N | Directional Neutral/Ground Overcurrent |

| 81df/dt | Rate of Change of Frequency |

| 81O | Overfrequency |

| 81U | Underfrequency |

| CTS | CT Supervision |

| PSL | Programmable Logic |

| SEF | Sensitive Earth Fault |

| TCS | Trip Circuit Supervision |

| VTS | VT Supervision |

MiCOM Agile P54x Models

P543 Line-Differential with Optional Subcycle Distance IED, in 60TE case

Buy Now

Manufacturing for P544 has been discontinued. As an alternative, please refer to P54.

P545 Line-Differential with Optional Subcycle Distance IED, in 80TE case

Buy Now

P546 Line-Differential with Optional Subcycle Distance IED, in 80TE case, suitable for two circuit breakers such as breaker-and-a-half

Buy Now

The P546 is under last-time buy. Orders may be placed until 15th June 2026 and will be fulfilled based upon availability. As an alternative, please refer to P54

MiCOM S1 Agile

Key benefits:

- Powerful, free of charge, PC toolsuite

- Optimum management of the installed base, structured as per the substation topology

- Intuitive and versatile interface with file management facilities

- Logical structure based on substation, voltage level and bay

- Version control and cross-checking facilities for IED settings

- Real-time measurement visualization – MiCOM S1 Agile extends to all MiCOM Agile IEDs - including P847 PMU and busbar schemes

Engineering Tool Suite

S1 Agile is the truly universal PC tool for MiCOM Agile relay, assemble all tools in a palette for simple entry, with intuitive navigation via fewer mouse-clicks. No-longer are separate tools required for redundant Ethernet configuration, phasor measurement unit commissioning, busbar scheme operational dashboards, programmable curve profiles or automatic disturbance record extraction – applications are embedded. MiCOM S1 Agile supports all existing MiCOM, K-Series and Modulex, including a utility for automatic conversion of setting files from previous generations of numerical relays like K-series and MiCOM P20 to the latest P40 Agile models.

To move to the future, with no loss of functionality, no loss of device support, and full compatibility with your installed base and system architecture – request a copy of S1 Agile with the contact form link below.

Key features in the MiCOM S1 family:

- GE Vernova’s integrated engineering tool that provides users with access to automation IED configuration and record data

- Integrated configuration and monitoring features

- Send and extract setting files

- Event and disturbance record extraction and analysis

MiCOM S1 Agile software request

To receive the MiCOM S1 Agile, please use our Contact form. This will also ensure that you are kept up-to-date with the latest enhancements, including updates and bug fixes.

Refurbishment Solutions - "If it's Blue Think to Renew"

GE Vernova’s latest MiCOM P540 series models offer an ideal path to refurbish an older installed base of MiCOM P540 relays. Whether those older products were initially sold as GE VERNOVA or AREVA-branded products, newer models retain pin-pin refurbishment capability. Advantageously, users can benefit from the advancements made in protection, control, communications, hardware and cybersecurity that have taken place in the intervening years. The new P40 retains form, fit and function compatibility but delivers the latest platform and software ready for today\’s environment, and for future-proofed application for the decades ahead.

Pin-Pin Upgrade Methodology:

- Take the order code (CORTEC) of the older relay being removed, typically a blue case relay

- Translate to today’s latest GE Vernova MiCOM model, adding Ethernet options if required

- Order the new P40 relay

- Extract settings and logic, use S1 Agile toolsuite to convert settings

- Detach the terminal blocks from old relay, leaving wiring attached / detach terminal blocks from the new.

- Carefully examine the terminal blocks to see that no physical damage has occurred since installation

- Mount new relay. Old relay blocks fit straight onto the new relay - safer, less wiring to reconnect.

- It is recommended to apply rated current and voltage to the relay CT/VT inputs during secondary injection testing to check the continuity of the CT/VT terminal block connections to the relay.

- Download converted files

- Test, return circuit to service with only minutes of downtime

LFCB and MITZ Replacement:

- GE Vernova’s P545/P546 relays and P590 interfaces fit directly into the space vacated by our legacy relays, offering a perfect functional match

- Please contact us for assistance

Recommended Products & services

Agile P652

Transformer Protection

The Agile P652 is a dedicated protection relay intended for protection of two winding transformers. The P652 relay performs an important role with its diagnostic features for improving asset health monitoring. These relays are “CE” marked for safety.

The P652 provides extensive protection functions including high-speed differential, inrush restraint, Restricted earth fault (high or low impedance modes), thermal overload, backup overcurrent / earth-fault /negative sequence overcurrent protection (HV and LV) and breaker failure detection for HV and LV breakers.

Agile P652

Transformer Protection

The Agile P652 is a dedicated protection relay intended for protection of two winding transformers. The P652 relay performs an important role with its diagnostic features for improving asset health monitoring. These relays are “CE” marked for safety.

The P652 provides extensive protection functions including high-speed differential, inrush restraint, Restricted earth fault (high or low impedance modes), thermal overload, backup overcurrent / earth-fault /negative sequence overcurrent protection (HV and LV) and breaker failure detection for HV and LV breakers.

Recommended Products & services

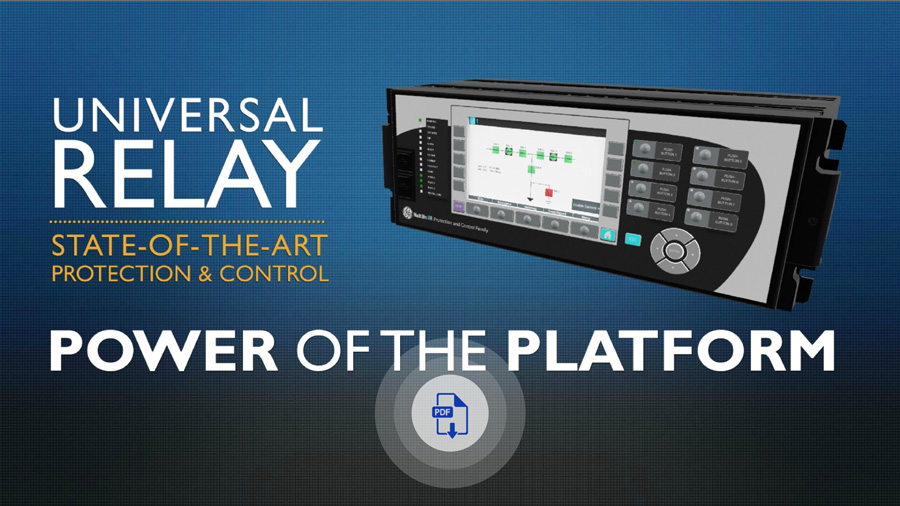

Multilin T35

Transformer Protection System

The T35 is designed to provide basic transformer protection functions for variety of transformer applications. It uses multiple current inputs to provide primary protection and backup protection of transformers, including differential, phase and ground overcurrent. The relay can be configured to accept up to 6 sets of current inputs to provide proper differential restraint for applications with three-winding transformers with windings configured in dual-breaker arrangements.

Multilin T35

Transformer Protection System

The T35 is designed to provide basic transformer protection functions for variety of transformer applications. It uses multiple current inputs to provide primary protection and backup protection of transformers, including differential, phase and ground overcurrent. The relay can be configured to accept up to 6 sets of current inputs to provide proper differential restraint for applications with three-winding transformers with windings configured in dual-breaker arrangements.

New and Enhanced Communication Capabilities

- New process bus module supports IEC 61869 sample values, PTP master capabilities and SV switching (FW 7.9x)

- New UR process bus modules supporting IEC61850-9-2LE Merging Units and IEC61850-9-2 Hardfiber (FW 7.8x) Module Training available here

- Support switchable IEC 61850 Ed. 1 and Ed. 2 and redundant SNTP (FW 7.7x)

- New UR front panel with integrated 7” color, graphical display - providing operators with enhanced situational awareness (FW 7.6x)

- High density I/O module supporting up to 120 inputs or up to 72 contact outputs – eliminating the need for additional discrete devices (FW 7.6x)

Cyber Security - CyberSentry UR (FW v7.xx)

CyberSentryTM enables UR devices to deliver full cyber security features that help customers to comply with cyber security requirements (NERC CIP, IEEE 1686, IEC 62443, etc):

- Secured firmware upgrade: FW file includes hash code that enables authentication prior to being used for upgrading UR Relay (FW 7.9x)

Extended Oscillography Records (FW v7.xx)

- Increased number of digital and analog channels (FW 7.90)

- Supports IEEE C37.111-1999/2013, IEC 60255-24 Ed 2.0 COMTRADE 2013 standard (FW v7.40)

- Configurable events allow for records of up to 45s at 64 samples per cycle

Extended Oscillography Records (FW v7.xx)

- Supports IEEE C37.111-1999/2013, IEC 60255-24 Ed 2.0 COMTRADE 2013 standard (FW v7.40)

- Configurable events allow for records of up to 45s at 64 samples per cycle

New and Enhanced Protection and Control Functionality

- Inter-turn transformer and dedicated Harmonic/Inrush detection elements (FW 8.0

- Expanded Bay Controller Capabilities – providing a one box solution (FW 7.6x)

- New thermal overload element (FW version 5.90)

- New CT failure element for increased current differential selectivity (FW version 7.00)

Key Benefits

- Percent restrained and unrestrained differential protection with inter-turn fault detection

- 2nd harmonic inrush inhibit and, and independent harmonic detection element

- TOC elements for backup protection

- Transducer I/Os (RTD & dcmA)

- FlexElements

- FlexCurves

Protection & Control

The T35 transformer protection system is a three-phase transformer relay designed to protect power transformers with up to six windings/restraints. The T35 provides for automatic or user-definable magnitude reference winding selection for CT ratio matching. The T35 performs automatic phase shift compensation for all types of transformer winding connections. The T35 algorithm allows the user to enable removal of the zero-sequence current even for delta-connected transformer windings, facilitating transformers with a variety of grounding configurations. As part of the Universal Relay (UR) Family, the T35 provides a cost-effective solution and superior protection and control.

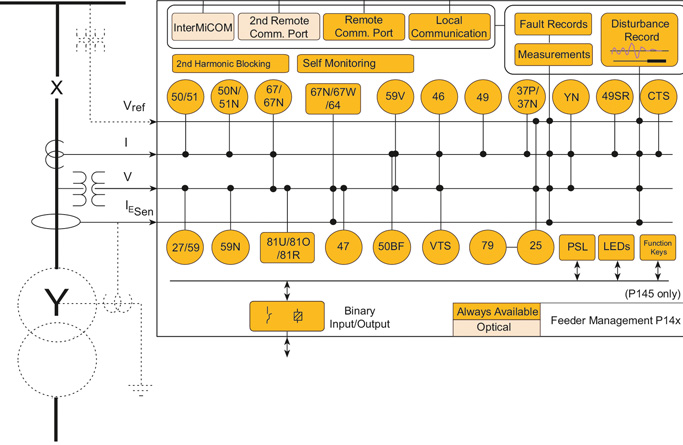

Functional Block Diagram

ANSI Device Numbers & Functions

| Device Number | Function |

|---|---|

| 49 | Thermal Overload |

| 50/87 | Instanataneous Differential Overcurrent |

| 51G | Ground Time Overcurrent |

| 50G | Ground Instantaneous Overcurrent |

| 50P | Phase Instantaneous Overcurrent |

| 51G | Ground Time Overcurrent |

| 51P | Phase Time Overcurrent |

| 81U | Underfrequency |

| 87RGF | Restricted Ground Fault |

| 87T | Transformer Differential |

| 87TF | Inter-turn transformer protection |

| TGFD | Transient ground fault detection |

Key Features

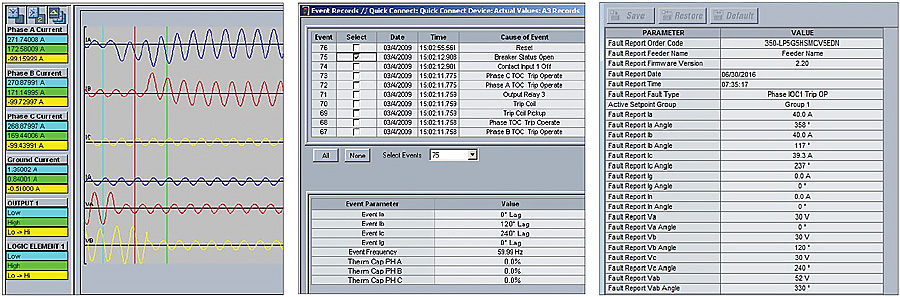

- Metering - current, voltage, power, energy, frequency, temperature

- Oscillography – analog and digital parameters at 64 samples/cycle

- Event Recorder - 1024 time tagged events with 0.5ms scan of digital inputs

- Data Logger - 16 channels with sampling rate up to 1 sample/cycle

- Setting for security audit trails for tracking changes to T35 configurations

Monitoring & Diagnostic

The T35 includes high accuracy metering and recording for all AC signals. Voltage, current, and power metering are built into the relay as a standard feature. Current and voltage parameters are available as total RMS magnitude, and as fundamental frequency magnitude and angle.

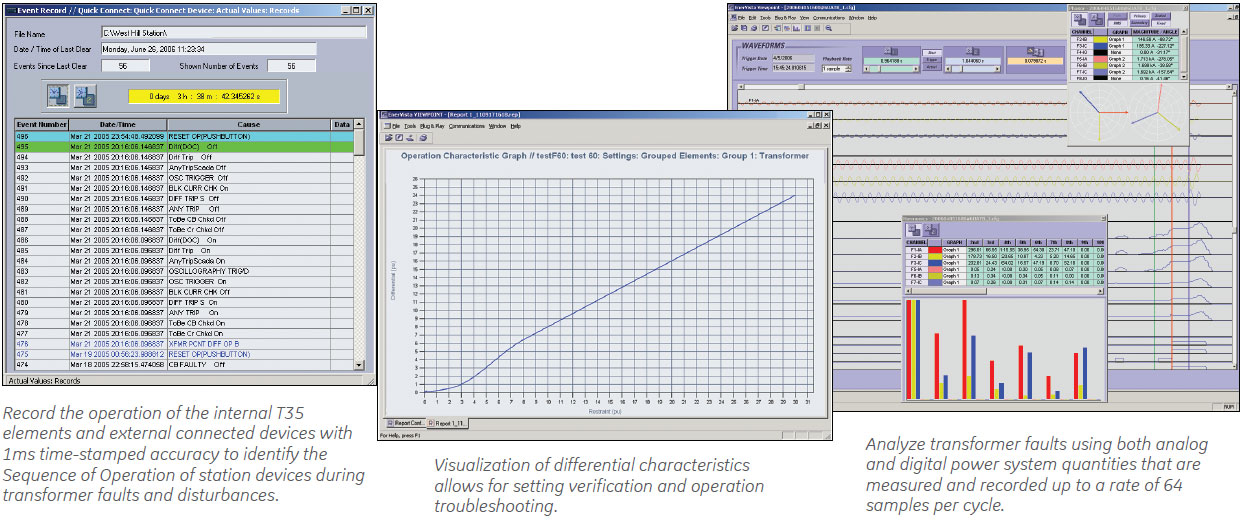

The T35 is the single point for protection, control, metering, and monitoring in one integrated device that can easily be connected directly into DCS or SCADA monitoring and control systems like Viewpoint Monitoring as shown.

The T35 is the single point for protection, control, metering, and monitoring in one integrated device that can easily be connected directly into DCS or SCADA monitoring and control systems like Viewpoint Monitoring as shown.

Advanced Automation

The T35 incorporates advanced automation features including powerful FlexLogic™ programmable logic, communication, and SCADA capabilities that far surpass what is found in the average transformer relay. The T35 integrates seamlessly with other UR relays for complete system protection.

FlexLogic allows for the customization of the T35 to operate and control the breakers and other auxiliary devices needed to fit most transformer protection schemes and applications.

FlexLogic allows for the customization of the T35 to operate and control the breakers and other auxiliary devices needed to fit most transformer protection schemes and applications.

Key Features

Complete IEC 61850 Process Bus solution providing resource optimization and minimizing total P & C life cycle costs

- Three independent 100Mbps Ethernet ports enable purpose specific LAN support that eliminates latency effect of heavy traffic protocols on mission critical communication services

- Embedded IEEE 1588 time-synch protocol support eliminates dedicated IRIG-B wiring requirements for IEDs

- Direct I/O secures high-speed exchange of binary data between URs

- Increase network availability by reducing failover time to zero through IEC62439-3 PRP, HSR or dual HSR support

Advanced Communications

The T35 provides advanced communications technologies for remote data and engineering access, making it easy and flexible to use and integrate into new and existing infrastructures. Direct support for fiber optic Ethernet provides high-bandwidth communications allowing for low-latency controls and high-speed file transfers of relay fault and event record information. The available three independent and redundant Ethernet options provide the means to create fault tolerant communication architectures in an easy, cost-effective manner.

The T35 supports the most popular industry standard protocols enabling easy, direct integration into DCS and SCADA systems.

- IEC 61850-9-2LE/IEC 61869 networked or IEC61850-9-2 Hardfiber process bus support

- DNP 3.0 (serial & TCP/IP)

- Ethernet Global Data (EGD)

- IEC 60870-5-103 and IEC 60870-5-104

- Modbus RTU, Modbus TCP/IP

- HTTP, TFTP, SFTP and MMS file transfer

- Redundant SNTP and IEEE 1588 for time synchronization

- PRP as per IEC 62439-3

- Supports Routable GOOSE (R-GOOSE)

Interoperability with Embedded IEC 61850

Use the T35 with integrated IEC 61850 to lower costs associated with power transformer protection, control and automation. GE Vernova’s leadership in IEC 61850 comes from thousands of installed devices and follows on years of development experience with UCA 2.0.

The T35’s IEC 61850 Process Bus module is designed to interface with the Multilin HardFiber System, allowing bi-directional IEC 61850 fiber optic communications. The HardFiber System is designed to integrate seamlessly with existing Universal Relay applications, including protection functions, FlexLogic, metering and communications. Learn more

The T35 can also connect to GE Vernova MU320 or third-party merging units using standard IEC 61869 or IEC 61850-9-2LE communication protocols.

Cyber Security - CyberSentry™ UR (FW v7.4xx)

CyberSentry enables UR devices to deliver full cyber security features that help customers to comply with NERC CIP and NITIR 7628 cyber security requirements through supporting the following core features:

Secure FW upgrade

UR FW files v7.9 and up now include a hash code that allows for authentication prior to being used for upgrading UR devices.

Password Complexity

Supporting up to 20 alpha- numeric or special characters, UR passwords exceed NERC CIP requirements for password complexity. Individual passwords per role are available.

AAA Server Support (Radius)

Enables integration with centrally managed authentication and accounting of all user activities and uses modern industry best practices and standards that meet and exceed NERC CIP requirements for authentication and password management.

Role Based Access Control (RBAC)

Efficiently administrate users and roles within UR devices. The new and advanced access functions allow users to configure up to five roles for up to eight configurable users with independent passwords. The standard “Remote Authentication Dial In User Service” (Radius) is used for authentication.

Event Recorder (Syslog for SEM)

Capture all cyber security related events within a SOE element (login, logout, invalid password attempts, remote/local access, user in session, settings change, FW update, etc), and then serve and classify data by security level using standard Syslog data format. This enables UR devices integration with established SEM (Security Event Management) systems.

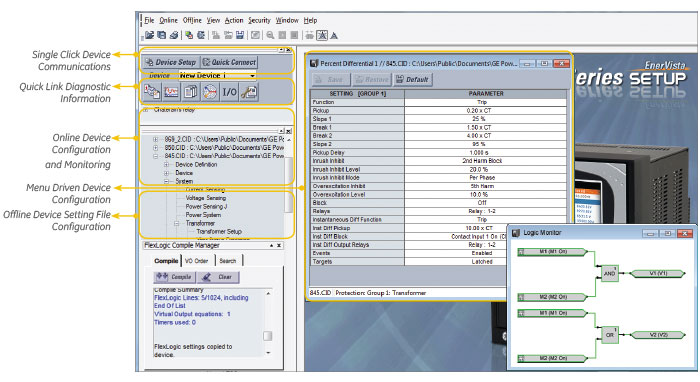

EnerVista™ Software

The EnerVista™ suite is an industry-leading set of software programs that simplifies every aspect of using the T35 relay. The EnerVista™ suite provides all the tools to monitor the status of the protected asset, maintain the relay, and integrate information measured by the T35 into DCS or SCADA monitoring systems. Convenient COMTRADE and Sequence of Events viewers are an integral part of the UR setup software included with every UR relay, to carry out postmortem event analysis and ensure proper protection system operation. Learn More

Recommended Products & services

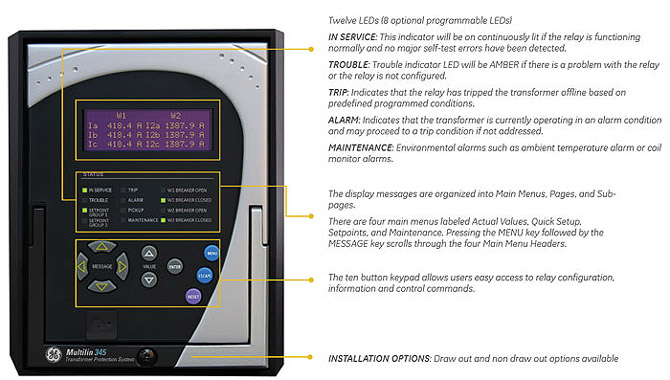

Multilin 345

Intuitive transformer protection

The Multilin™ 345 is a member of the Multilin 3 Series protective relay platform and has been designed for the protection, control and management of power transformers as primary or backup protection device. The 345 provides advanced transformer protection, control and monitoring in one economical draw-out or non draw-out design. The 345 contains a full range of self-contained protection and control elements as well as advanced communications, metering, monitoring and diagnostics.

Multilin 345

Intuitive transformer protection

The Multilin™ 345 is a member of the Multilin 3 Series protective relay platform and has been designed for the protection, control and management of power transformers as primary or backup protection device. The 345 provides advanced transformer protection, control and monitoring in one economical draw-out or non draw-out design. The 345 contains a full range of self-contained protection and control elements as well as advanced communications, metering, monitoring and diagnostics.

Key Benefits

- Dual slope with unique dual breakpoint differential protection with Unrestrained differential

- Second harmonic inrush and fifth harmonic over-excitation inhibits

- Thermal Overload and restricted Ground Fault (RGF/87G)

- Comprehensive overcurrent elements

- Breaker failure and lockout functions

- Logic elements

Protection & Control

The 345 transformer protection system is designed to protect and control small to medium size power transformers. Flexible and powerful, the 345 provides advanced transformer protection, control and monitoring in one economical draw-out design. The 345 contains a full range of self-contained protection and control elements as detailed in the Functional Block Diagram and in the Features table. The 345 can be even used for dual feeder protection.

Key Features

- Comprehensive metering

- Event Recorder: 256 events (1ms time stamping)

- Programmable oscillography up to 32 samples per cycle and digital states and Fault Report

- 4X20 character LCD display

- Control panel with 12 LED indicators

- Relay health diagnostics and Breaker monitoring

- Security and password control

- SNTP or IRIG-B time synchronization

Power System Troubleshooting

Analyze power system disturbances with transient fault recorder and event records

Metering, Monitoring & Diagnostics

The 345 continuously measures and computes the following AC signals indicating the health of the protected transformer:

- Phase winding currents

- Winding ground current

- Winding neutral current

- Winding negative sequence current

- Differential and restraint currents per-phase

- Winding ground differential current

- Percent 2nd and 5th harmonics differential currents per phase

- Percent thermal capacity per-phase

- Current demand

The states of all digital inputs/outputs are provided through the actual values either from the summary pages or individually. This includes:

- States pf virtual inputs

- States of remote inputs

- States of relay outputs

- States of logic elements

Key Features

- Front USB and rear serial, Ethernet and Fiber ports

- Multiple Protocols: IEC 61850, MODBUS TCP/IP, MODBUS RTU, DNP 3.0, IEC60870-5-104, IEC60870-5-103

Advanced Communications

The 345 utilizes the most advanced communication technologies today making it the easiest and most flexible transformer protection relay to use and integrate into new and existing infrastructures. Multiple communication ports and protocols allow control and easy access to information from the 345. The 345 supports the most popular industry standard protocols enabling easy, direct integration into electrical SCADA and HMI systems. Modbus RTU is provided as standard with a RS485 networking port.

The following optional protocols are available:

- IEC 61850

- IEC 61850 GOOSE

- DNP 3.0

- Modbus RTU

- Modbus TCP/IP

- IEC 60870-5-103

- IEC 60870-5-104

These protocols make it easy to connect to a Utility or Industrial automation system, eliminating the need for external protocol converter devices.

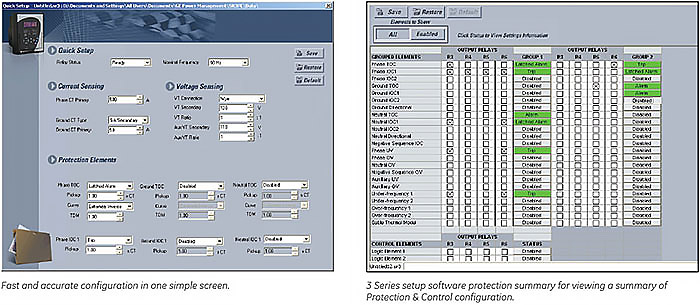

EnerVista™ Software

The EnerVista™ suite is an industry leading set of software programs that simplifies every aspect of using the 345 relay. The EnerVista™ suite provides all the tools to monitor the status of the protected asset, maintain the relay, and integrate the information measured into DCS or SCADA monitoring systems. Convenient COMTRADE and sequence of event viewers are an integral part of the 345 setup software and are included to ensure proper protection and system operation. Learn More

Feeder protection settings in one easy step

Access Control

Multilin devices and relays are designed with simple but powerful security to enable reliability and compliance for virtually any project or implementation. Password security is an optional feature of the 3 Series which can be setup using the SR3 EnerVista Setup software. The password system has been designed to facilitate a hierarchy for centralized management. This is accomplished through a Master level access password which can be used for resetting lower level access passwords and higher level privileged operations.

Auditing and Reporting

With the Security Audit Trail reporting feature, available in GE Vernova’s ViewPoint Monitoring software, operators are able to obtain Event logging reports of key activities such as configuration changes. These preformatted reports can be used to help ensure device and protection system integrity and perform forensic auditing of activities and changes for compliance.

Trace any setting changes with security audit trail.

Trace any setting changes with security audit trail.

Key Features

- 4 line display for easy viewing of key data

- 12/10 LED indicators for quick diagnostics

- Programmable LED indicators for specific targets

- Draw out or non draw out design options

Hardware

Inputs and Outputs

The 345 features the following inputs and outputs for monitoring and control of typical transformer applications:

- 10 contact Inputs with programmable thresholds

- 2 Form A outputs for breaker trip and close with coil monitoring and 5 Form C output relays

Drawout & Non-Drawout Construction

The 345 is offered in both a drawout or a non-drawout construction. In the drawout case design the 345 simplifies installation and improves site safety as the need to open switchgear doors or rewire the device after testing is eliminated.

The 345 protection relay chassis used with a draw out relay is available separately, for use as a partial replacement or in test environments. The draw out relay with no chassis is also available to order as a spare unit.

Drawout & Non-Drawout Construction

Removable terminals ease wiring and in-system testing or troubleshooting.

Drawout

Drawout

Non-drawout

Non-drawout

User Interface

Recommended Products & services

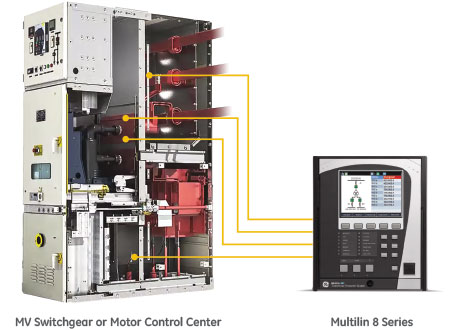

Multilin 845

Comprehensive Protection & Management for Transformers

The Multilin™ 845 Transformer Protection System is a member of the Multilin 8 Series protective relay platform and has been designed for the protection, control and management of 2- and 3-winding power and distribution transformers in both utility and industrial applications.

Multilin 845

Comprehensive Protection & Management for Transformers

The Multilin™ 845 Transformer Protection System is a member of the Multilin 8 Series protective relay platform and has been designed for the protection, control and management of 2- and 3-winding power and distribution transformers in both utility and industrial applications.

Full Color Graphical HMI Front Display

A large, full color Graphic Control Panel (GCP) ensures clear representation of critical status and measurements. The 8 Series offers two options for front panels:

- 10 Programmable Push buttons with 12 programmable LEDs

- 3 Programmable Push buttons and 12 programmable LEDs

Switchgear Control and Configurable SLD

The Multilin 8 Series provides a configurable dynamic SLD up to six (6) pages for comprehensive switchgear control of up to 3 breakers and 9 disconnect switches; including interlocks. Up to 15 digital and metering status elements can be configured per SLD page.

Platform Overview

The Multilin 8 Series platform delivers the highest level of quality, reliability and performance with…

Innovative Technology & Design

- Patented environmental monitoring and diagnostics helps visibility on change in environmental parameters

- Advanced, flexible and embedded communications: IEC® 61850 Ed2, IEC 62439/PRP, Modbus® RTU & TCP/IP, DNP3.0, IEC 60870-5-104, IEC 60870-5-103

- Single setup and configuration across the platform

- Field swappable power supply

- Draw-out design simplifies testing, commissioning and maintenance, thereby increasing process uptime

- Optional Wi-Fi connectivity minimizes system configuration and provides safe relay programming and diagnostic retrieval

- Elimination of electrolytic capacitors

Exceptional Quality & Reliability

- IPC A-610-E Class 3 Manufacturing standards – highest industry standards for electronic manufacturing

- Highest reliability standards for electronics testing

- Environmental Stress Screening and full functional testing

- Rated for IP54 applications

- Standard Harsh Conformal Coating

Uncompromising Service & Support

- Covered under GE Vernova’s 10 year warranty plan

- Fully designed, tested and assembled at GE Vernova facilities

Multilin 845 Overview

The 845 has been designed for the protection, control and management of 2- and 3-winding power and distribution transformers in both utility and industrial applications. The 845 delivers comprehensive transformer health monitoring, diagnostics, and reporting with integrated connectivity to single and multi-gas transformer DGA solutions such as, GE Vernova’s Kelman Transformer Monitoring devices, delivering actionable analytics for asset optimization and life extension.

Applications:

- Primary and back-up protection and management of small, medium and larger power and distribution transformers, autotransformers and reactors

- Designed for Utility (Transmission & Distribution) or Industrial applications

- Integrated transformer protection, monitoring diagnostics and transformer health visualization

Multilin 845 feeder protection relay functional block diagram

ANSI Device Numbers & Functions

| Device Number | Function |

|---|---|

| 24 | Volts per Hertz |

| 25 | Synchrocheck |

| 27X | Auxiliary Undervoltage |

| 27P | Phase Undervoltage |

| 32 | Directional Power |

| 49 | Hottest Spot Temperature Aging Factor Loss of Life |

| 50/87 | Instantaneous Differential Overcurrent |

| 50BF | Breaker Failure |

| 50G | Ground Instantaneous Overcurrent |

| 50N | Neutral Instantaneous Overcurrent |

| Device Number | Function |

|---|---|

| 50P | Phase Instantaneous Overcurrent |

| 50_2 | Negative Sequence Instantaneous Overcurrent |

| 51G | Ground Time Overcurrent |

| 51N | Neutral Time Overcurrent |

| 51_2 | Negative Sequence Time Overcurrent |

| 55 | Power Factor |

| 59N | Neutral Overvoltage |

| 59P | Phase Overvoltage |

| 59X | Auxiliary Overvoltage |

| 59_2 | Negative Sequence Overvoltage |

| Device Number | Function |

|---|---|

| 67G | Ground Directional Element |

| 67N | Neutral Directional Element |

| 67P | Phase Directional Element |

| 81O | Overfrequency |

| 81U | Underfrequency |

| 81R | Frequency Rate of Change |

| 87G | Restricted Ground Fault (RGF) |

| 87T | Transformer differential |

| AFP | Arc Flash Protection |

| VTFF | Voltage Transformer Fuse Failure |

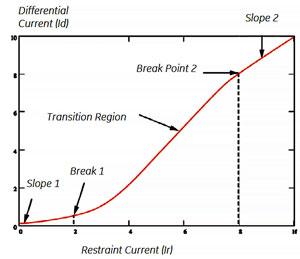

The settings for the dual-slope, dual-breakpoint characteristic provides higher flexibility for shaping up the characteristic and achieving better sensitivity and security.

The settings for the dual-slope, dual-breakpoint characteristic provides higher flexibility for shaping up the characteristic and achieving better sensitivity and security.

Percent Differential Protection

The 845 provides enhanced security by including both restrained and unrestrained (instantaneous) differential protection. The percent differential element is based on a configurable dual-breakpoint/dual-slope differential restraint characteristic with inrush and overexcitation inhibits based on 2nd & 5th harmonics. The restraint current is calculated as a maximum of the internally compensated currents for better through-fault stability under CT saturation conditions.

The percent characteristic allows the element to account for both DC and AC saturation of the current transformers.

The “cubic spline” curve characteristics enables the relay to perform accurately for restraint current in range between the two slope breakpoints

Integrated Arc Flash Protection

The Multilin 8 Series supports an integrated arc flash module providing constant monitoring of an arc flash condition within the switchgear, motor control control centers, or panelboards. With a 2ms protection pass, the 8 Series is able to detect light and overcurrent using 4 arc sensors connected to the 8 Series relay. In situations where an arc flash/fault does occur, the relay is able to quickly identify the fault and issue a trip command to the associated breaker thereby reducing the total incident energy and minimizing resulting equipment damage.

Self-monitoring and diagnostics of the sensors ensures the health of the sensors as well as the full length fiber cables. LEDs on the front panel display of the 845 can be configured to indicate the health of the sensors and its connections to the relay.

Fast, reliable arc flash protection with light-based arc flash sensors integrated within the Multilin 8 Series of protection & control devices. With arc flash detection in as fast as 2msec, the costs associated with equipment damage and unplanned downtime

Fast, reliable arc flash protection with light-based arc flash sensors integrated within the Multilin 8 Series of protection & control devices. With arc flash detection in as fast as 2msec, the costs associated with equipment damage and unplanned downtime

Monitoring & Diagnostics

The Multilin 845 includes high accuracy metering and recording for all AC signals. Voltage, current, and power metering are built into the relay as a standard feature. Current and voltage parameters are available as total RMS magnitude, and as fundamental frequency magnitude and angle.

Data Logging & Learned Data

The 845 captures key electrical and DGA data values during transformer energization to trend and analyze transformer performance. Data is summarized and presented to operators through a pre-formatted Health Report to clear indication of changes to measured parameters. Up to 365 records are supported within the 845 relay. Up to 365 latest records are supported in the 845 relay. The data, when input cumulatively to the transformer model screens helps in visualizing trends and correlating key transformer electrical and DGA parameters.

Trip and Close Circuit Monitoring

The 845 relay provides Trip and Close Circuit Monitoring elements

Breaker Arcing Current

This element calculates an estimate of the per-phase wear on the breaker contacts by measuring and integrating the current squared passing through the breaker contacts as an arc. When the threshold is exceeded in any phase, the relay can set an output operand and set an alarm.

Breaker Health

The 845 relay provides breaker health information by monitoring and analyzing the operation count, arcing energy of breaking current, arcing time, tripping time, closing time and spring charging time if applicable.

Integrated Electrical and DGA for Comprehensive Transformer Monitoring & Diagnostics

The Multilin 845 offers advanced transformer health monitoring and diagnostics through advanced notification of potential issues before they become critical. The Multilin 845 features detailed learned data, summarized pre/post-fault records, and integration with GE Vernova’s DGA devices to collect, trend, and analyze a transformer’s fault gases. This enables operators to minimize costly unplanned outages and equipment failures.

Environmental Monitoring

The 845 implements a patented environmental monitoring system that measures and provides operating condition information. Reliable and secure operation of the 845 relay and other electronic devices in the vicinity may be affected by environmental factors. The 845 relay has been designed to meet or exceed all required industry standards. Some operating conditions may be beyond those standards and reduce total lifespan of the device.

Communications

The 845 provides advanced communications technologies for remote data and engineering access, making it easy and flexible to use and integrate into new and existing infrastructures. Direct support for copper/fiber optic Ethernet provides high-bandwidth communications, allowing for low-latency controls and high-speed file transfers of relay fault and event record information. The 845 also supports two independent IP addresses, providing high flexibility for the most challenging of communication networks. Two independent network ports enables the 845 to connect with the primary protection network and the secondary monitoring network to deliver integrated asset monitoring and diagnostics by combining protection and DGA data.

Providing several Ethernet and serial port options and supporting a wide range of industry standard protocols, the 845 enables easy, direct integration into DCS and SCADA systems. The 845 supports the following protocols:

- IEC 61850 Ed2, IEC 62439 / PRP

- DNP 3.0, IEC 60870-5-103, IEC 60870-5-104

- Modbus RTU, Modbus TCP/IP

The 845 has two interfaces as USB front port and Wi-Fi for ease of access to the relay. Wi-Fi Connectivity:

- Simplify set-up and configuration

- Simplify diagnostic retrieval

- Eliminate personnel in front of switchgear

- WPA-2 security

Cybersecurity

The 869 cyber security enables the device to deliver full cyber security features that help operators to comply with NERC CIP guidelines and regulations.

AAA Server Support (Radius/LDAP)

Enables integration with centrally managed authentication and accounting of all user activities and uses modern industry best practices and standards that meet and exceed NERC CIP requirements for authentication and password management.

Role Based Access Control (RBAC)

Efficiently administrate users and roles within UR devices. The new and advanced access functions allow users to configure up to five roles for up to eight configurable users with independent passwords. The standard “Remote Authentication Dial In User Service” (Radius) is used for authentication.

Event Recorder (Syslog for SEM)

Capture all cyber security related events within a SOE element (login, logout, invalid password attempts, remote/local access, user in session, settings change, FW update, etc), and then serve and classify data by security level using standard Syslog data format. This will enable integration with established SEM (Security Event Management) systems.

Software & Configuration

The EnerVista™ suite is an industry-leading set of software programs that simplifies every aspect of using the Multilin 845.

EnerVista provides all the tools to monitor the status of the protected asset, maintain the device and integrate the information measured by the Multilin 8 Series, into SCADA or DCS process control systems. The ability to easily view sequence of events is an integral part of the setup software, as postmortem event analysis is critical to proper system management.

EnerVista Launchpad

The setup tools within Launchpad allow for the configuration of devices in real-time, by communicating via serial, Ethernet or modem connections, or offline by creating device setting files to be sent to devices at a later time.

8 Series Setup Software

8 Series Setup Software is single setup and configuration tool across the platform and can reduce device setup and configuration time.

Simplified Setup & On-Going Maintenance

8 Series Retrofit

Retrofit Existing SR 745 Devices to the Multilin 845 in Minutes

Traditionally, retrofitting an existing relay has been a challenging, time consuming task often requiring re-engineering, new drawings, panel modifications, re-wiring and re-testing.

The 8 Series Retrofit provides a quick, 3-step solution to upgrade previously installed SR 745 relays. With the new 8 Series Retrofit users are able to install the 845 Transformer System without modifying existing cutouts and wiring, and without any drawing changes or re-engineering time.

Easy 3-Step Process to Upgrade in as Fast as 21 Minutes

EnerVista 8 Series Setup Software provides automated setting file conversion. Once completed, a graphical report is provided to verify and call out any specific settings that may need attention.

Simply remove the upper, lower and low voltage terminal blocks and then remove the SR chassis from the panel. No need to disconnect any of the field wiring.

Insert the new 8 Series Retrofit chassis into the switchgear and simply plug-in the old terminal blocks - there is no need to make any cut-out modifications or push and pull cables.

Recommended Products & services

P64 MiCOM 5th Generation

Transformer Protection Relays - P642, P643, P645

The P64, part of the MiCOM P40 Agile 5th Generation family is a transformer protection relay that helps preserve transformer service life and provides fast protection for transformer faults with a graphical HMI as standard. The platform consists of three model variants (P642, P643 and P645) that cover two and three-winding transformers (including auto-transformers), with up to five sets of 3-phase CT inputs, and offers high and low impedance restricted earth fault, and has integral asset management capability.

P64 MiCOM 5th Generation

Transformer Protection Relays - P642, P643, P645

The P64, part of the MiCOM P40 Agile 5th Generation family is a transformer protection relay that helps preserve transformer service life and provides fast protection for transformer faults with a graphical HMI as standard. The platform consists of three model variants (P642, P643 and P645) that cover two and three-winding transformers (including auto-transformers), with up to five sets of 3-phase CT inputs, and offers high and low impedance restricted earth fault, and has integral asset management capability.

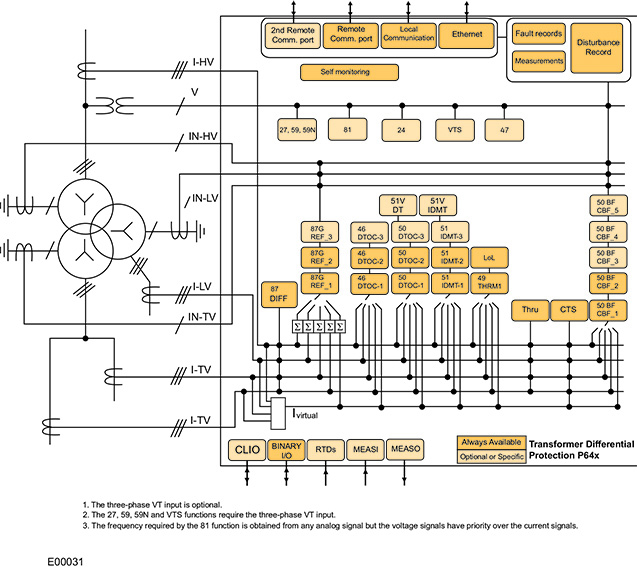

Overview

Transformers are high capital assets in electrical power systems. Elimination of all electrical and mechanical stresses, although desirable to preserve transformer life, is impractical. Adaptive techniques to measure, alarm (or trip) and advise on cumulative service can help to schedule preventive maintenance before a costly failure occurs. Internal faults are a risk for all transformers, with short-circuits dissipating the highest localized energy. Unless cleared quickly, the possibility to rewind windings reduces and core damage may become irreparable.

GE Vernova's P642, P643 and P645 address all these issues, preserving service life and offering fast protection for transformer faults. A transient bias technique has been included, enhancing relay stability and CT requirements. Hosted on an advanced IED platform, the P64x incorporates differential, REF, thermal, and overfluxing protection, plus backup protection for uncleared external faults. Model variants cover two and three-winding transformers (including auto-transformers), with up to five sets of 3-phase CT inputs.

Key benefits:

- Backup and logging of through faults

- Simple settings – wizard requires only nameplate data

- Integrated backup overcurrent per winding or CT input - optional directionalizing when relay fitted with a 3-phase VT

- Ordering the 3-phase VT permits full monitoring and measurement of power and energy quantities

Main characteristics:

- Current loop analogue inputs [CLIO] and analogue outputs [RTD] for remote monitoring

- Optional single or dual redundant Ethernet available for IEC 61850

- Transient biasing reduces CT knee point dimensioning by typically 25% compared to historical applications

ANSI ® Device Numbers and Functions

| Device Number | Function |

|---|---|

| 24 | Overfluxing |

| 27 | Undervoltage |

| 46 | Negative Sequence Overcurrent |

| 47 | Negative Sequence Overvoltage |

| 49 | Thermal Overload |

| 50 | Phase Definite Time Overcurrent |

| 51 | Phase Inverse-Time Overcurrent |

| 52 | Circuit Breaker Control |

| 59 | Overvoltage |

| 67 | Directional Phase Overcurrent |

| Device Number | Function |

|---|---|

| 68 | Inrush Detection |

| 89 | Latching/Lockout Contacts |

| 50BF | CB Failure |

| 50N | Earth Fault Definite Time Overcurrent |

| 51N | Neutral/Ground IDMT Overcurrent |

| 51R | Voltage Restrained Overcurrent |

| 51V | Voltage Controlled Overurrent |

| 59N | Neutral Voltage Displacement |

| 64N | Restricted Earth Fault |

| 67N | Directional Neutral/Ground Overcurrent |

| Device Number | Function |

|---|---|

| 81O | Overfrequency |

| 81U | Underfrequency |

| 87T | Transformer Differential |

| CLIO | Current Loop Transducer I/O |

| CTS | CT Supervision |

| LoL | Loss of Life |

| PSL | Programmable Logic |

| RTD | Temperature Measurement |

| TCS | Trip Circuit Supervision |

| Thru | Through Fault Monitoring |

| VTS | VT Supervision |

Agile P64x Models

| P64 5th Generation transformer management IED | Buy Now |

MiCOM S1 Agile

Key benefits:

- Powerful, free of charge, PC toolsuite

- Optimum management of the installed base, structured as per the substation topology

- Intuitive and versatile interface with file management facilities

- Logical structure based on substation, voltage level and bay

- Version control and cross-checking facilities for IED settings

- Real-time measurement visualization – MiCOM S1 Agile extends to all MiCOM Agile IEDs - including P847 PMU and busbar schemes

Engineering Tool Suite

S1 Agile is the truly universal PC tool for MiCOM Agile relay, assemble all tools in a palette for simple entry, with intuitive navigation via fewer mouse-clicks. No-longer are separate tools required for redundant Ethernet configuration, phasor measurement unit commissioning, busbar scheme operational dashboards, programmable curve profiles or automatic disturbance record extraction – applications are embedded. MiCOM S1 Agile supports all existing MiCOM, K-Series and Modulex, including a utility for automatic conversion of setting files from previous generations of numerical relays like K-series and MiCOM P20 to the latest P40 Agile models.

To move to the future, with no loss of functionality, no loss of device support, and full compatibility with your installed base and system architecture – request a copy of S1 Agile with the contact form link below.

Key features in the MiCOM S1 family:

- GE Vernova's integrated engineering tool that provides users with access to automation IED configuration and record data

- Integrated configuration and monitoring features

- Send and extract setting files

- Event and disturbance record extraction and analysis

MiCOM S1 Agile software request

To receive the MiCOM S1 Agile, please use our Contact form. This will also ensure that you are kept up-to-date with the latest enhancements, including updates and bug fixes.

Refurbishment Solutions

GE Vernova’s latest P64 MiCOM 5th Generation models offer a perfect functional match for our MBCH and KBCH family of transformer differential relays, from the heritage installed-base brands GEC Measurements, GEC Alsthom, GE VERNOVA and Areva:

Advantages:

- Same 4U rack mounting format

- KBCH, P642/P643/P645 share the same S1 Agile PC toolsuite

- Contact us for advice and support

Recommended Products & services

SPO

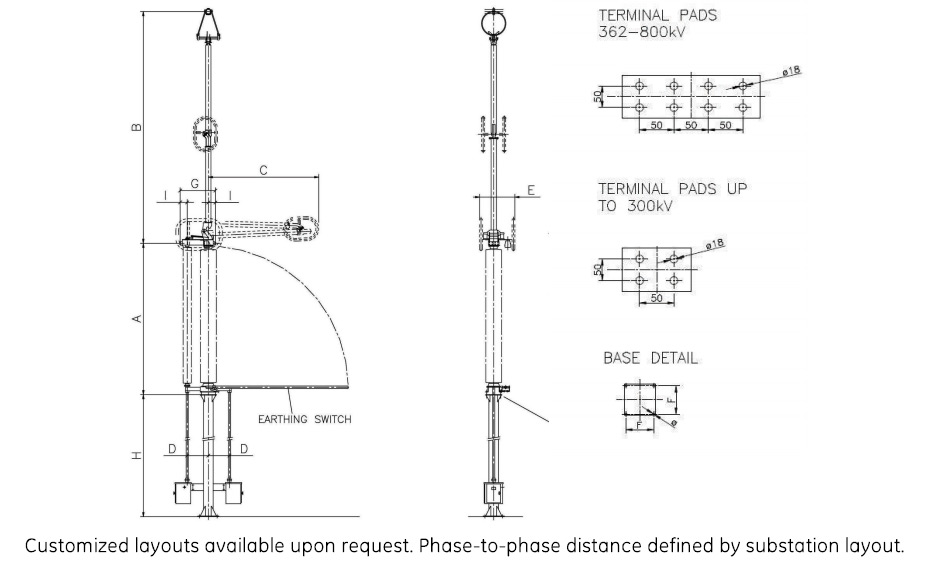

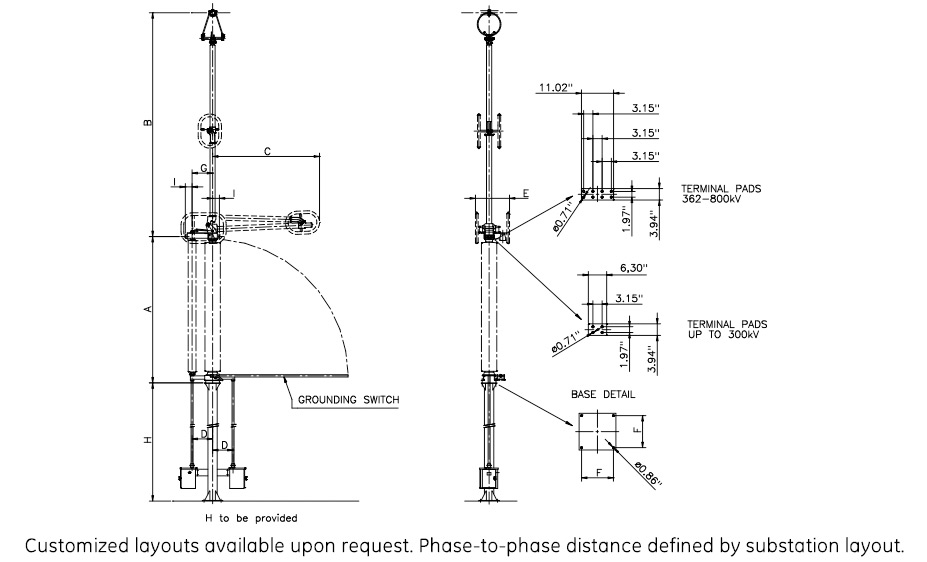

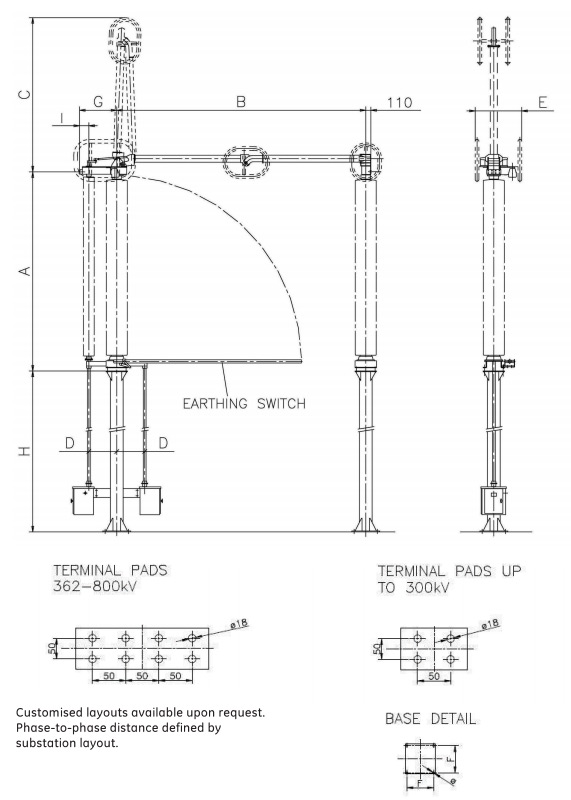

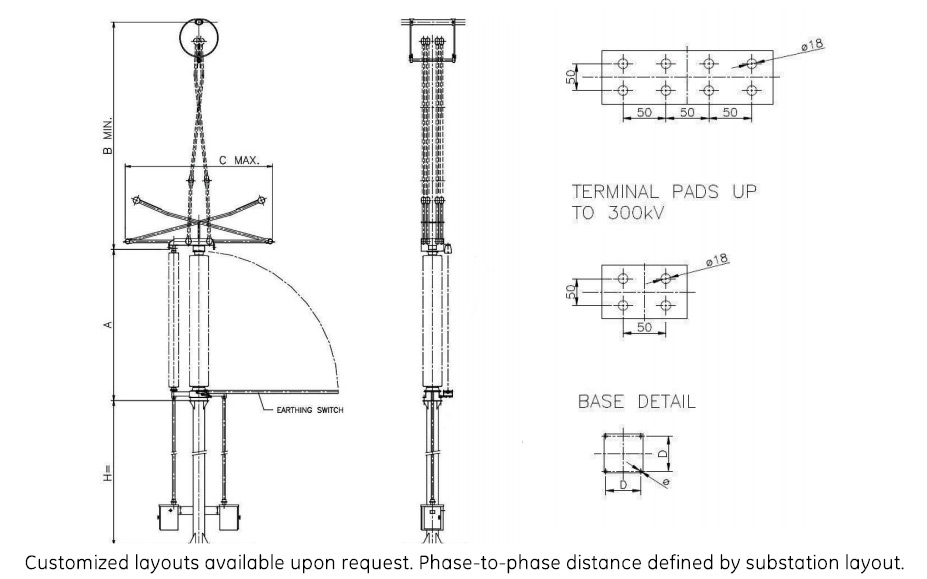

Knee Type Disconnector up to 1,200 kV

GE Vernova’s SPO is a vertical break disconnector with a two-piece arm. In the open position the blade sections fold upon themselves in a vertical plane of only 60% of the longitudinal dimension.

SPO

Knee Type Disconnector up to 1,200 kV

GE Vernova’s SPO is a vertical break disconnector with a two-piece arm. In the open position the blade sections fold upon themselves in a vertical plane of only 60% of the longitudinal dimension.

- Substation crossing structures and wires can be lower and less expensive than conventional vertical break disconnectors

- Low center of gravity for live part provides high performance during earthquakes and faster, smoother and rebound-free operation

- Virtually maintenance free with factory-sealed bearings, life-time greased or self-lubricating parts and corrosion-free materials

Specifications

Technical Data (ANSI)

| Rated Voltage | Rated Current A/ Short time current kA | BIL kV | A inches | B inches | C inches | D inches | E inches | F inches | G inches | H inches |

|---|---|---|---|---|---|---|---|---|---|---|

| 245 kV | 4000/63 | 1050 | 8' 4 1/4" | 9' 10" | 5' 7" | 1' 4 3/4" | 1' 7 3/4" | 1' 1 1/2" | 1' 1 1/2" | 6 3/4" |

| 362 kV | 4,000/63 | 1300 | 9' 9 1/2" | 12' 1 3/4" | 7' 8 1/2" | 1' 11 1/2" | 2' 7 1/2" | 1' 3 3/4" | 2' 7 1/2" | 7 3/4" |

| 550 kV | 4,000/63 | 1800 | 13' 74 1/2" | 17' 6 3/4" | 9' 4 1/2" | 1' 11 1/2" | 3' 3 3/4" | 1' 3 3/4" | 2' 7 1/2" | 7 3/4" |

| 800 kV | 4,000/63 | 2050 | 17' 1 1/4" | 19' 8 1/4" | 12' 7 1/2" | 1' 11 1/2" | 3' 3 3/4" | 1' 3 3/4" | 2' 7 1/2" | 7 3/4" |

Drawings

Recommended Products & services

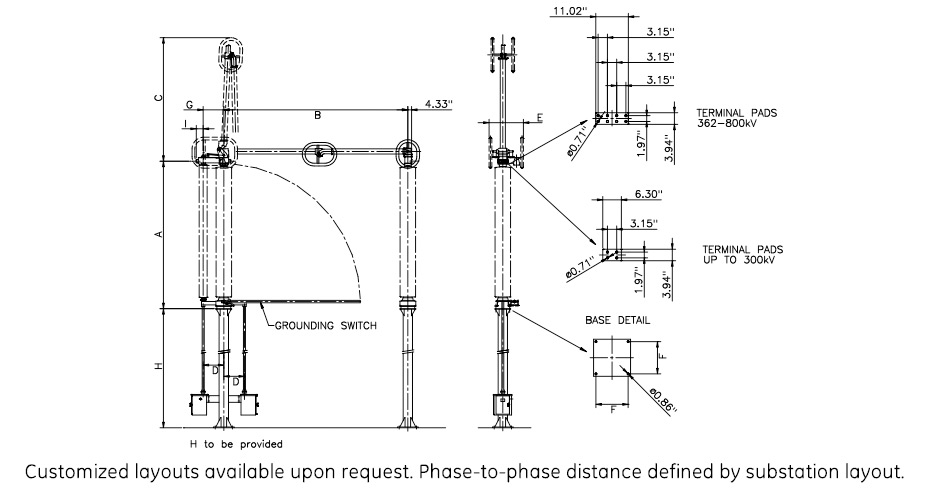

SX

Pantograph Disconnector up to 550 kV

The SX is a space saving double scissor aluminium disconnector connecting the lower busbar to the upper one via the pantograph arms. Horizontal rather than vertical separation means a space reduction of as much as 30%.

Customer Benefits

- Clear conducting routing for safety

- Rigid or flex busbars for flexibility

- Double scissor design for high rigidity

- Built-in ground switches available

- Virtually maintenance free

- Easy start-up and commissioning

SX

Pantograph Disconnector up to 550 kV

The SX is a space saving double scissor aluminium disconnector connecting the lower busbar to the upper one via the pantograph arms. Horizontal rather than vertical separation means a space reduction of as much as 30%.

Customer Benefits

- Clear conducting routing for safety

- Rigid or flex busbars for flexibility

- Double scissor design for high rigidity

- Built-in ground switches available

- Virtually maintenance free

- Easy start-up and commissioning

- Rugged performance in adverse conditions including high winds, heavy ice or seismic conditions, stable in closed position during short circuits

- Blades are tubular aluminium with replaceable silver-plated copper contacts

- Galvanized structural steel channel base supports the insulators and live parts, providing high strength and rigid design

- All bearings and counter-balancing springs are isolated from the main path

- Reduction of encumbrance for rated voltage above 300 kV due to special design of bearing frame which allowed the removal of anti-corona rings

- Clear busbar arrangement and routing results in increased safety during operation and maintenance

- Flexible installation and arrangement configurations

- Available Life Cycle Assessment on request

- Available the supply of recycled material to reduce environmental impact on request

Specifications

Technical Data (IEC)

| Rated Voltage | Rated Current A/ Short time current kA Up to | BIL kV | A mm | B mm | C mm | D mm | Ø mm |

|---|---|---|---|---|---|---|---|

| 72.5 kV | 4000/63 | 325 | 980 | 2000 | 1400 | 340 | 22 |

| 100 kV | 4000/63 | 450 | 1230 | 2200 | 1500 | 340 | 22 |

| 123 kV | 3150/50 | 550 | 1480 | 2500 | 1600 | 340 | 22 |

| 145 kV | 4000/63 | 650 | 1710 | 3000 | 2000 | 340 | 22 |

| 170 kV | 4000/63 | 750 | 1910 | 3000 | 2000 | 340 | 22 |

| 245 kV | 4000/80 | 1050 | 2510 | 3650 | 2650 | 340 | 26 |

| 300 kV | 4000/80 | 1050 | 2810 | 3650 | 2650 | 340 | 26 |

| 362 kV | 4000/80 | 1175 | 3100 | 4400 | 3100 | 400 | 26 |

| 420 kV | 4000/80 | 1425 | 3550 | 5450 | 4100 | 400 | 26 |

| 550 kV | 4000/80 | 1550 | 4200 | 5800 | 4300 | 400 | 26 |

Drawings

Recommended Products & services

SPV

Semi-Pantograph Disconnector up to 1,000 kV

The SPV is a space saving vertical reach disconnector connecting the lower busbar to the upper one via the semi-pantograph arm. Horizontal rather than vertical separation means a space reduction of as much as 30%.

Customer Benefits

- Reduced substation space requirements (up to 30%)

- Clear conducting routing for safety

- Rigid or flex busbars for flexibility

- Built-in or retro-fitted earthing switches

- Virtually maintenance free

- Easy start-up and commissioning

SPV

Semi-Pantograph Disconnector up to 1,000 kV

The SPV is a space saving vertical reach disconnector connecting the lower busbar to the upper one via the semi-pantograph arm. Horizontal rather than vertical separation means a space reduction of as much as 30%.

Customer Benefits

- Reduced substation space requirements (up to 30%)

- Clear conducting routing for safety

- Rigid or flex busbars for flexibility

- Built-in or retro-fitted earthing switches

- Virtually maintenance free

- Easy start-up and commissioning

- Blades are extra heavy, one piece, tubular aluminium with replaceable silver plated copper contacts at each end

- Galvanized structural steel channel base supports the insulators and live parts, providing high strength and rigid design

- All bearings and counter-balancing springs are isolated from the main path

- Clear busbar arrangement and routing results in increased safety during operation and maintenance

- In open position, blade sections fold upon themselves, offering maximum dimension slightly greater than half the open gap dimension.

- More compact than a standard pantograph switch and streamlined contours reduce RIV and corona effects

- Flexible installation and arrangement configurations

- Virtually maintenance free with factory-sealed bearings, life-time greased or self-lubricating parts and corrosion-free materials

Specifications

Technical Data (IEC)

| Rated Voltage | Rated Current A/ Short time current kA Up to | BIL kV | A mm | B mm | C mm | D mm | E mm | F mm | G mm | i mm | Ø mm |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 72.5 kV | 4000/63 | 325 | 980 | 1700 | 600 | 425 | 500 | 340 | 765 | 170 | 22 |

| 340 kV | 4000/63 | 450 | 1230 | 1900 | 700 | 425 | 500 | 340 | 765 | 170 | 22 |

| 123 kV | 4000/63 | 550 | 1480 | 2200 | 980 | 425 | 500 | 340 | 765 | 170 | 22 |

| 142 kV | 4000/63 | 650 | 1710 | 3000 | 1300 | 425 | 500 | 340 | 765 | 170 | 22 |

| 170 kV | 4000/63 | 750 | 1910 | 3000 | 1300 | 425 | 500 | 340 | 765 | 170 | 22 |

| 245R kV | 4000/63 | 950 | 2310 | 3800 | 1700 | 425 | 500 | 340 | 765 | 170 | 22 |

| 245 kV | 4000/63 | 1050 | 2510 | 3800 | 1700 | 425 | 500 | 340 | 765 | 170 | 22 |

| 300 kV | 4000/63 | 1050 | 2860 | 4200 | 1900 | 425 | 500 | 340 | 765 | 170 | 26 |

| 362 kV | 4000/63 | 1175 | 3190 | 4800 | 2200 | 600 | 800 | 400 | 1000 | 200 | 26 |

| 420 kV | 4000/63 | 1425 | 3640 | 5300 | 2600 | 600 | 800 | 400 | 1000 | 200 | 26 |

| 550 kV | 4000/63 | 1550 | 4290 | 6700 | 3500 | 600 | 1000 | 400 | 1000 | 200 | 26 |

| 800 kV | 4000/63 | 2100 | 5490 | 8000 | 4000 | 600 | 1100 | 500 | 1000 | 200 | 34 |

Drawings