Overview

Managed Services

Managed Services offerings leverage our expertise in automation and control to help you with your day to day operations. Using secure remote support and advanced analytics, our expert personnel can become an extension of your team to ensure our products and services are utilized to their maximum potential.

From process and energy intensive industries to utility applications, put us to work for you.

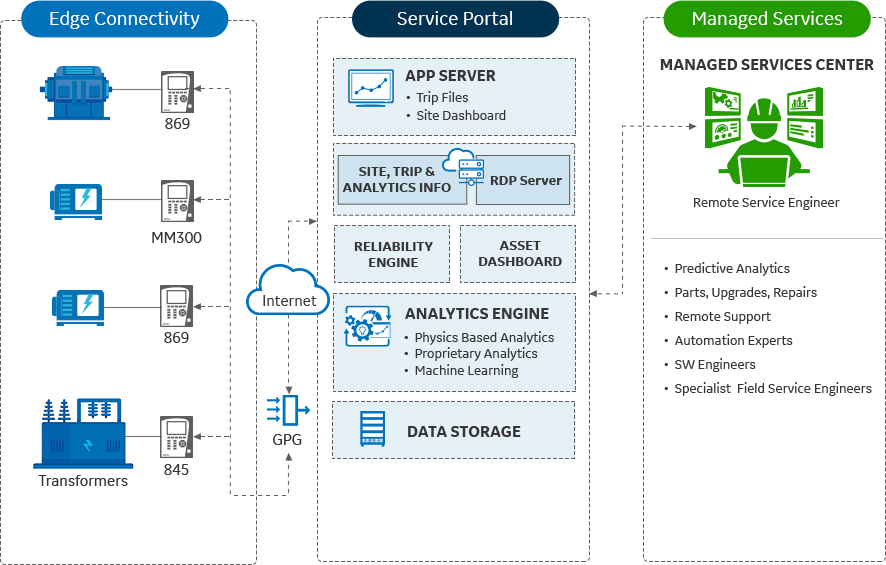

Motor Health Management

Our Motor Health Management services leverage the latest in condition-based asset health monitoring solutions available in our protection and control relays to deliver high-accuracy monitoring of your critical motors. Using our advanced health algorithms, based on Electrical Signature Analysis (ESA), our motor protection relays can provide early detection of electrical, mechanical or thermal abnormalities, before they become critical failures that bring your process to unexpected halt.

Our managed services team works with customers to make sure that the health algorithms are properly tuned for different motor types and technologies and that the settings are updated over time to adjust for maintenance operations, replacement and operational adjustments. Our managed services team examines all the algorithms alarms in the first instance to ensure that all alarms are true alarms, therefore minimizing false positives.

Our Motor Health Management services leverage the latest in condition-based asset health monitoring solutions available in our protection and control relays to deliver high-accuracy monitoring of your critical motors. Using our advanced health algorithms, based on Electrical Signature Analysis (ESA), our motor protection relays can provide early detection of electrical, mechanical or thermal abnormalities, before they become critical failures that bring your process to unexpected halt. Our managed services team works with customers to make sure that the health algorithms are properly tuned for different motor types and technologies and that the settings are updated over time to adjust for maintenance operations, replacement and operational adjustments. Our managed services team examines all the algorithms alarms in the first instance to ensure that all alarms are true alarms, therefore minimizing false positives.

CASE STUDIES MOTOR HEALTH MANAGEMENT

Motor As A Sensor For The Mechanical Drive-Train

GE Vernova & Customer's joint analysis identified a high correlation between alarms raised by the analytics and maintenance requirements on mechanical components.

Customer Benefit

New analytics helped the customer move from time-based maintenance to condition-based maintenance, using the motor as a sensor for the mechanical drive-train.

Generator Foundation Vibration Detection

GE Vernova & Customer's collaborative effort to analyze a high number of bearing alarms, identified a correlation with generator foundation vibration.

Customer Benefit

New analytics helped the customer detect when generators required maintenance. The result was longer maintenance intervals which in turn resulted in O&M savings.

Electrical Network Disturbances Detection

GE Vernova's Service team determined a high correlation between shorted stator-turn alarms and network disturbances at plant problems.

Customer Benefit

Identification of unknown electrical network issues through generator monitoring. The analytics used were able to discriminate between generator & network problems.

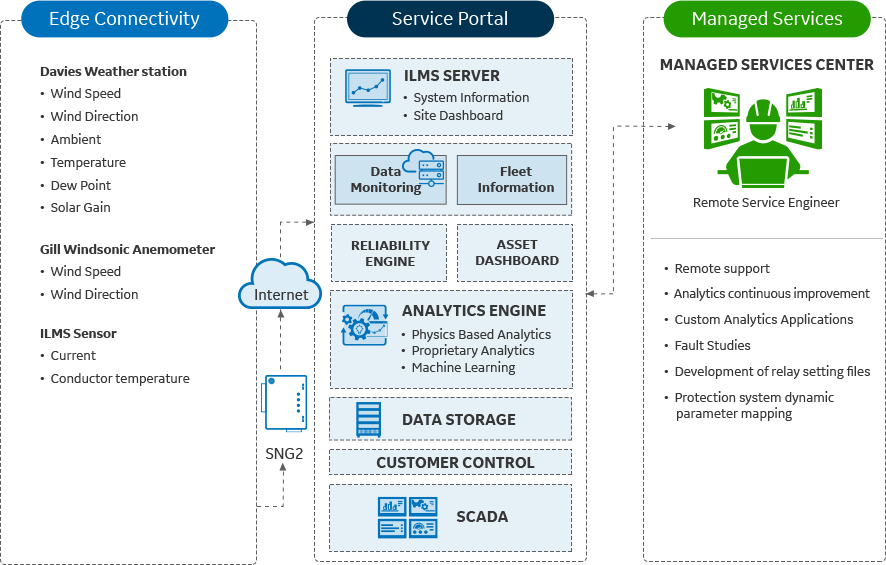

Intelligent Line Management Services

Getting more from your existing distribution network:

By implementing an intelligent line monitoring system, many of our customers have been able to migrate from a static line rating to a dynamic line rating approach, which resulted in improved management and utilization of the distribution network.

One of the biggest hurdles to making this move is the algorithm required to compute the new line ratings as it requires application specific data such as real-time load and environmental conditions.

Through our Intelligent Line Management Services, our team works to ensure that all application data including operational experience is leveraged to tune and improve the algorithm – ensuring maximized performance and reliability in the distribution system.

By implementing an intelligent line monitoring system, many of our customers have been able to migrate from a static line rating to a dynamic line rating approach, which resulted in improved management and utilization of the distribution network. One of the biggest hurdles to making this move is the algorithm required to compute the new line ratings as it requires application specific data such as real-time load and environmental conditions. Through our Intelligent Line Management Services, our team works to ensure that all application data including operational experience is leveraged to tune and improve the algorithm – ensuring maximized performance and reliability in the distribution system.

CASE STUDIES INTELLIGENT LINE MONITORING SYSTEM

Increasing Network Capacity

Investigation of solutions to increase network capacity, required to connect and manage increasing levels of demand.

Customer Benefit

An additional network carrying capacity of around 11% unlocked by deploying the ILMS system.

Real Time Thermal Rating

Real time rating project created to determine the value in capacity uplift using the thermal rating as compared with static rating on overhead lines.

Customer Benefit

Significant capacity uplift demonstrated between 27% and 74% at various sites.