Static Var Compensator Solutions

Increasing Grid Reliability

GE Vernova’s Static Var Compensator (SVC) solutions are a cost-effective and efficient means to provide dynamic voltage support and maintain the reliability and efficiency of power supply. These solutions are highly reliable, easy to integrate into both existing and new infrastructures, and reduce the investment required for building new network extensions.

GE Vernova provides a broad range of SVC configurations with two types of SVC design, classic and patented Main Reactor, and every solution is customized based on the utility’s technical and economic requirements.

Static Var Compensator Solutions

Increasing Grid Reliability

GE Vernova’s Static Var Compensator (SVC) solutions are a cost-effective and efficient means to provide dynamic voltage support and maintain the reliability and efficiency of power supply. These solutions are highly reliable, easy to integrate into both existing and new infrastructures, and reduce the investment required for building new network extensions.

GE Vernova provides a broad range of SVC configurations with two types of SVC design, classic and patented Main Reactor, and every solution is customized based on the utility’s technical and economic requirements.

GE Vernova Advantage

GE Vernova’s SVC solutions are customized based on the utility’s technical and economic requirements for their network such as fault level and load parameters. GE Vernova provides an extensive services portfolio comprised of feasibility and network studies, project management, engineering capabilities, equipment, installation services and long term maintenance contracts, delivering an integrated and robust system that provides utilities with the following competitive advantages.

Model Based Design Control ensures optimal and accurate performance of the SVC by direct deployment into the system software

- Rapid technical responsiveness to the customer, from planning support and project execution to commissioning

- Intuitive graphical interface provides fast, automatic, and error free code generation from control models, ensuring a greater level of confidence to the customer

- Ease of integration into control system software with power system modeling tools such as PSCAD provides an accurate representation of system performance for planning and transients analysis

- Modular hardware design based on commercial off-the-shelf components which provide extensive scalability to any project rating, while maintaining quick system delivery time and simple life-cycle Management

Classic SVC and GE Vernova’s patented Main Reactor SVC provides more design flexibility to ensure optimized system performance

- Broad range of SVC configurations including: classic, hybrid, Main Reactor, fixed, modular, relocatable, low noise, and reduced footprint designs

- Ground level power to the thyristor valves provide system voltage independence and benefits operation at very low voltages, increasing SVC readiness during severe system events

- Unique Main Reactor configuration improves harmonic performance, reduces operational losses and design footprint, and ensures regulatory compliance at the point of interconnection

Manufacturing excellence and deep domain technical expertise providing full system lifecycle support resulting in simplified and streamlined commercial offerings

- Deep technical expertise gained though more than 50 years’ experience on more than 380 global installations ranging from small industrial to large utility projects, in diverse applications and extreme environmental conditions

- Full range of lifecycle support competencies including network analysis, system design, engineering, procurement, civil works, installation, testing and commissioning and asset management, eliminating project and logistical complexities of multiple vendor projects

- SVC main components are vertically integrated within GE Vernova’s advanced manufacturing facilities, which are certified to ISO 9001, ISO 14001 Environmental Standards and OHSAS 18001

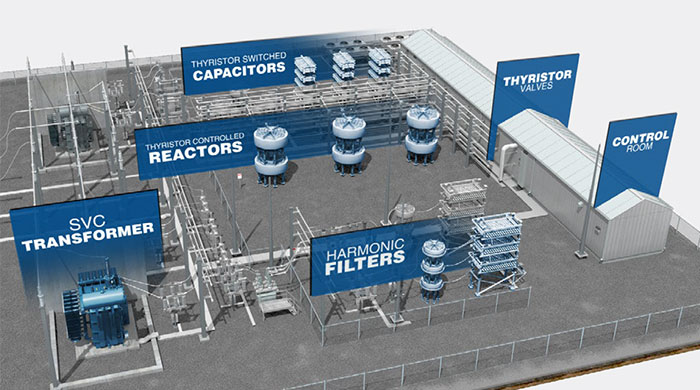

GE Vernova’s Classic SVC Design

-100/+200Mvar classic SVC design

-100/+200Mvar classic SVC design

GE Vernova’s Classic SVC design is customized based on the utilities key requirements for system performance. Every system is tested extensively during factory acceptance testing and site commissioning to ensure guaranteed performance.

Benefits of classic SVC design:

- Allows grid operators to gain accurate control of network reactive power and voltage

- Increases power transfer capability

- Improves steady-state and dynamic stability of the grid with very fast response times

Main components of the system include:

- SVC transformers

- Thyristor Controlled Reactors (TCR)

- Thyristor Switched Capacitors (TSC)

- Harmonic Filters

- Advanced Thyristor Valve (ATV)

- Advanced Digital Control (ADC)

- Protection and Auxiliary systems

- Thyristor valve cooling system

System ratings include:

- Typical utility voltage levels: approx. 69 < kV < 800

- Typical utility overall ratings: approx. 40 < Mvar <1,200

Example of a classic SVC design

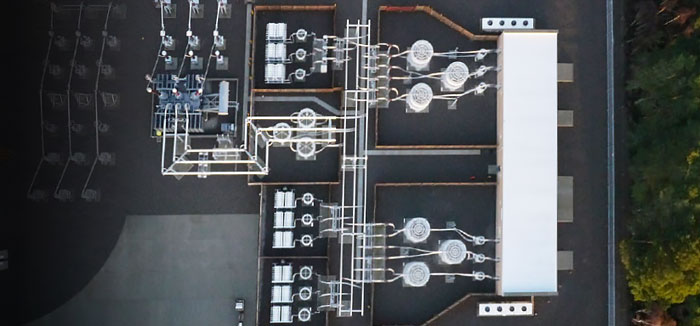

-100/+200Mvar Main Reactor design, with smaller footprint

-100/+200Mvar Main Reactor design, with smaller footprint

GE Vernova’s Patented Main Reactor SVC Design

GE Vernova’s patented Main Reactor SVC design is customized based on the utility’s key requirements for system performance. Every system is tested extensively during factory acceptance testing and site commissioning to ensure guaranteed performance.

Traditionally, the SVC medium voltage bus is connected directly to the SVC coupling transformer, but with the main reactor configuration there is a reactor connected between SVC bus and coupling transformer.

The Main Reactor concept efficiently isolates harmonics, even in demanding network conditions. This design requires fewer harmonic filters enabling a compact, optimized SVC layout.

The Main Reactor has many other inherent benefits for improved harmonics, simpler design and cost savings, including:

- Main Reactor blocks harmonics generated by the SVC

- Lower amount of filtering is needed

- Improved harmonic distortion at the Point of Common Coupling

- Less harmonic stress on the SVC coupling transformer

- Lower voltage stress on all components

- Minimized requirement for Thyristor Switched Capacitors (TSC), potentially eliminated

- Thyristor Controlled Reactors (TCR) has smaller coils, lower losses and reduced number of thyristor valve levels

- Only low order filters are needed (reactor blocks high order), wide filtering band can be used

Main components of the system include:

- SVC Transformers

- Thyristor Controlled Reactors (TCR)

- Main Reactor

- Harmonic filters

- Advanced Thyristor Valve (ATV)

- Advanced Digital Control (ADC)

- Protection and Auxiliary systems

- Thyristor valve cooling system

Example of a Main Reactor SVC design

Advanced Digital Control platform for SVC systems

Advanced Digital Control platform for SVC systems

GE Vernova’s Advanced Digital Control for SVC Systems

GE Vernova’s approach to SVC Control System represents the latest in design methodology by utilizing a powerful Model Based Design approach. With this approach the SVC Control System software is built using a core library of complex control algorithms that represents over 50 years of FACTS experience within GE Vernova. Model Based Design utilizes a graphical interface for the design stage and translation of control models with automatic code generation for all testing and verification stages. With this approach, GE Vernova has enhanced the quality, reliability, and maintainability of the Advanced Digital Control system for SVCs.

Model Based Design Advantages

- With Model Based Design, programming and customization of control functions is simplified by the use of a graphical programming interface.

- Testing and verification of the control system at the design stage starts early using real-time control models in closed loop with the SVC power electronics and the power grid.

- Simulation environment uses real-time control models providing the most accurate representation of control performance. The control models can be easily exported to PSCAD™ or similar tools with one-to-one representation for further testing and simulations.

- Automatic code generation allows direct conversion of graphical control models into real-time control software, eliminating the manual “coding stage”, resulting in improved quality and reliability.

- Complete traceability of customer requirements throughout the control model provides easy and efficient way for software modifications and new feature implementation at any stage of the project.

- Model Based Design approach adopted by GE Vernova has already revolutionized the development approach for critical control software in aviation, space and automotive industries, resulting in significant improvement in software quality for critical and life-supporting applications.

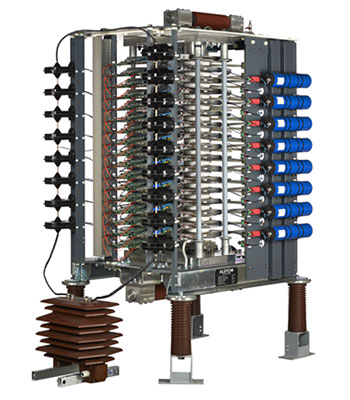

GE Vernova's Advanced Thyristor Valve

GE Vernova's Advanced Thyristor Valve

Thyristor Controlled Reactor and Thyristor Switched Capacitors

Thyristor valves are used for controlling reactive power in Static Var Compensators. Thyristor Controlled Reactor (TCR) valves are used to control the effective fundamental frequency current in the reactors by controlling the conducting ratio through varying the firing angle of the thyristors. Thyristor Switched Capacitors (TSC) bank valves are used for switching capacitor banks on or off according to the reactive power demand on a time scale of several periods or more.

Advanced Thyristor Valve for SVC Systems

The Advanced Thyristor Valve (ATV) is GE Vernova’s latest range of liquid-cooled thyristor valves for Static Var Compensator applications. These thyristor valves have been developed by drawing on GE Vernova’s extensive experience of more than 50 years of applying thyristor based SVCs both for transmission and industrial applications. The ATV provides a very compact, versatile and standardized platform for both TCR and TSC variants.

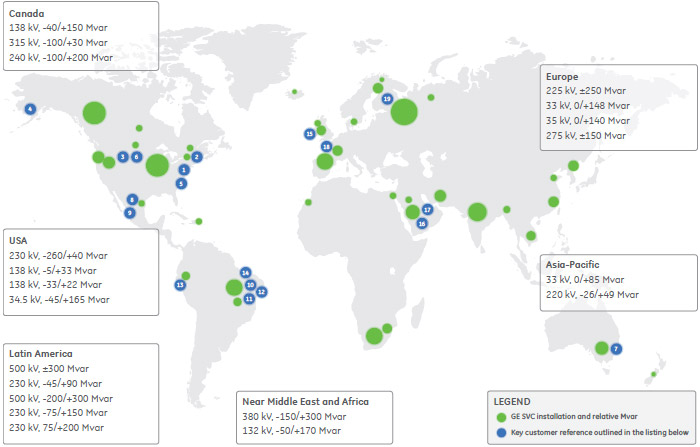

GE Vernova Experience

GE Vernova has designed, delivered and supports over 380 Static Var Compensator Systems globally in a broad range of applications and environments. The below details are a selected representation of recent projects, a complete reference list is available upon request.

Customer References

- Location: West Wharton, NJ, USA

Rating: -260/+40 Mvar, 230 kV - Location: St-Marc-de-Figuery, Canada

Rating: -100/+300 Mvar, 315 kV - Location: Alberta, Canada

Rating: -100/+200 Mvar, 240 kV - Location: Alaska, USA

Rating: Refurbishment of 3 SVCs - (-22 to +22 Mvar) - Wasilla,

AK-(-5 to +33 Mvar) - Fairbanks, AK-(-33 to +22 Mvar) - Healy, AK - Location: Roanoke, VA, USA

Rating: -45/+165 Mvar, 34.5kV (138 kV) - Location: Pasqua, Saskatchewan, Canada

Rating: -40/+150 Mvar in 2x(-20/+75) Mvar, 138 kV - Location: State of Victoria, Australia

Rating: -26/+49 Mvar, 220 kV - Location: Veracruz, Mexico

Rating: -60/+180 to 0/+240 Mvar, 34.5 kV - Location: Mexicali, Mexico

Rating: -75/+200 Mvar, 230 kV - Location: Brazil

Rating: -200 / +300 Mvar, 500 kV - Location: Brazil

Rating: -75 / +150 Mvar, 230 kV - Location: Brazil

Rating: -75 / +150 Mvar, 230 kV - Location: Peru

Rating: ±15 Mvar, 138 kV - Location: Imbirussu, Brazil

Rating: ±100 Mvar, 230 kV - Location: Scotland, UK

1st Installation of GE Vernova’s patented Main Reactor design

Rating: -150 / +150 Mvar, 275 kV - Location: Quway’iyah, Saudi Arabia

Rating: +170 /-50 Mvar SVC - Location: Saudi Arabia

Rating: +300/-150 Mvar SVC and expansion of 110kV GIS at 380kV BSP and two 110kV, 100Mvar bus connected shunt capacitors at 380kV BSP - Location: La Merlatiere and Domloup, France

Patented Main Reactor Design

Rating: ±250 Mvar at 225 kV - Location: Kangasala, Finland

Rating: -200/+240 Mvar, 400 kV - Location: Albany, New Zealand

Rating: ±100 Mvar, 220 kV