Industry Leading Experience

GE Vernova’s Industrial Communications Professional Services offers a range of services and project management capabilities that can be tailored to provide a fully engineered, deployed, and supported system to meet application specific needs.

The services and project management offerings are a result of years of experience building multivendor and multi-technology communication networks worldwide. From network planning and systems design to project and program management, GE Vernova has a proven track record implementing communication networks for diverse applications.

Key Benefits

- Access to technical expertise that utilizes state-of-the-art tools and highly experienced system designs

- Minimizes overall costs and reduces risks through the provision of a guaranteed working design

- Proven processes identify and reduce risks and failure modes prior to implementation

- Single point of contact helps ensure timely implementation within scope and on budget

- GE Vernova engineering engagement allows tailoring of products to meet customer’s specific needs

Industry Leading Experience

GE Vernova’s Industrial Communications Professional Services offers a range of services and project management capabilities that can be tailored to provide a fully engineered, deployed, and supported system to meet application specific needs.

The services and project management offerings are a result of years of experience building multivendor and multi-technology communication networks worldwide. From network planning and systems design to project and program management, GE Vernova has a proven track record implementing communication networks for diverse applications.

Key Benefits

- Access to technical expertise that utilizes state-of-the-art tools and highly experienced system designs

- Minimizes overall costs and reduces risks through the provision of a guaranteed working design

- Proven processes identify and reduce risks and failure modes prior to implementation

- Single point of contact helps ensure timely implementation within scope and on budget

- GE Vernova engineering engagement allows tailoring of products to meet customer’s specific needs

MDS Wireless Services

GE Vernova’s Industrial Communications professional services team has a long history and extensive experience in supporting organizations of all sizes in implementing reliable and scalable communication networks. GE Vernova’s team will tailor their services and project management solutions to meet a broad range of customer requirements and communication networking applications that can easily scale where required

GE Vernova provides a broad range of services to support projects in a variety of industrial environments including:

Application Networking Services-

GE Vernova can provide the following as part of their application networking services:

- New or modified network design, including IP addressing / subnetting and router configuration.

- Seamlessly integrate GE Vernova and non-GE Vernova equipment into a communications network.

- Manage and install security certificates or an entire security infrastructure

- Set up and install cell-enabled radios to comply with existing contract requirements. Will arrive on-site ready to activate to a customer’s cellular network and servers.

Propagation Analysis -

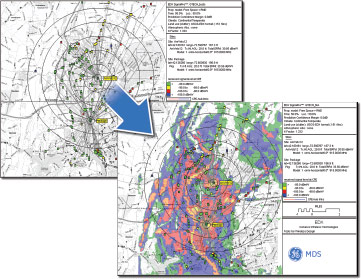

For any network design, whether a thousand remotes that need to be monitored or a single point- to-point link, there must be a guarantee that stations can communicate within the service level requirements customers expect.

Based on site details including the latitude, longitude, antenna mounting height, a software modeling tool is utilized to predict the wireless coverage for the equipment needed to meet your application requirements. GE Vernova has extensive proven field experience in modeling the predicted coverage and propagation analysis reporting.

Traffic Modeling -

GE Vernova analysts work closely with customers to understand their unique application characteristics and traffic patterns. The information is utilized to tailor a model to predict the data traffic flow in the system and provide an optimal network design which utilizes every possible bps available.

Based on site details including the latitude, longitude, antenna mounting height, a software modeling tool is utilized to predict the wireless coverage for the equipment needed to meet your application requirements. GE Vernova has extensive proven field experience in modeling the predicted coverage and propagation analysis reporting.

Requisition Engineering -

Detailed bills of materials, drawings and instructions will be provided for customers during a project implementation resulting in decreased implementation time and enabling ease of system deployment.

Customized Packaged Models -

GE Vernova’s services team has extensive experience designing, building, installing and commissioning customized packaged models. Model components can include GE Vernova and/or 3rd party radios, power supplies, batteries, RTUs and sensors. Customized enclosures are available on request.

Onsite System Optimization -

GE Vernova’s team of expert analysts can conduct studies on existing system sites, examine current setups, and make recommendations for improving network performance. These studies include, but are not limited to, examining the following components: antenna and feedline systems, signal levels and interference, radio configurations, and firmware versions.

Wireless Projects

GE Vernova’s Industrial Communications Professional Services Process are based on years of experience and several deployments across multiple applications and industries, GE Vernova has developed a Professional Services Process (PSP) that allows us to partner with our customers for successful project implementations. GE Vernova’s PSP was developed over several years based on extensive experience in various industrial environments. It is a comprehensive process designed to be very application specific and is enhanced after every project

Regardless of the size or scope of a project, GE Vernova assigns a project manager to oversee all of the activities and associated details to ensure a successful project implementation. The details below outline a typical project management process:

Phase 1: Defining Scope of WorkThe first phase of a network communications project is to gather information about the customer’s requirements. The following activities will take place during the definition phase of a project:

Phase 2: Analyzing the EnvironmentThe analysis phase of the communications project allows engineers o validate the initial concept design and verify that it meets the customer’s expectations by providing the following:

Phase 3: Developing the Final Network DesignDuring the design phase, the network design is finalized and ready to be implemented to meet the customer’s scope of work and requirements. GE Vernova can provide the following during this stage:

|

Phase 4: Project Implementation

During project implementation, the following activities take place:

- File regulatory agency required spectrum documentation and procure all necessary equipment.

- Assemble the network communications devices, conduct factory assessment testing, oversee commissioning of the equipment, and complete network audits to ensure system performance.

- Prepare knowledge transfer and training materials on system operations and maintenance.

- Provide on-site training for a smooth transition of the project.

Phase 5: Supporting our Customers

GE Vernova can continue support of the implemented system and provide the following services:

- Access to an authorized local partner close to your facility for troubleshooting and replacement.

- A call center with access to technical services for assistance in troubleshooting system issues or general product questions or on-site support if required.

- A hosted or on-site network operations center for systems monitoring and diagnosis.

Lentronics Hardened Optical Network Services

Engineering

GE Vernova’s team of telecommunications engineers can provide support from budgetary quotes to full scale, turnkey projects, including:

- Final system design and configuration of equipment

- Engineering drawings including:

- Wiring and block diagrams

- Traffic plans and system layouts

- Equipment profiles and node assignment drawings

- Custom installation instructions

- Custom field test specifications

- Customer witness tests (CWT)

Field Service

Project Management

A wide variety of field services are offered to customers including:

- Installation, testing and commissioning of systems

- Startup services

- On site assistance

- Hands-on training

- System upgrades

- Customized services as required

- Firm price quotation or Time & Expense (T&E)

The Lentronics Multiplexers team ensures on time and on budget completion of projects by:

- Developing and maintaining project schedules

- Monitoring deliverables and project milestones

- Expediting when necessary

- Coordinating GE Vernova, customer and contractor resources

- Conducting project meetings

Racks & Custom Enclosures

Our equipment integration designs are developed with detailed attention to equipment placement and accessibility. Offerings include both standard and custom packages for wireless device integration and networking accessories. Standards-based procedures for equipment integration and testing ensure that wireless systems are robust and future-proof.

Custom Enclosures & Integration Services

- Standardized offerings or custom designs

- Integration of radios, multiplexers, switches and routers with power supplies, antennas and cables

- Offering open frame racks, NEMA enclosures, or custom enclosures

- Ability to pursue industry safety certifications

- Complete documentation provided

- System level documentation

- Rack level documentation

- Site level documentation

Industrial Communications Classroom, Virtual & e-Learning Courses

GE Vernova’s Industrial Communications training is offered in a wide variety of platforms and topics to provide flexibility in time, location and skill level. From attendance in on-site classroom courses to virtual course attendance, self-paced e-learning videos and customized courses, GE Vernova’s training provides customers with high-quality knowledge to be safe, efficient and successful in industrial wireless communications.

This training is ideal for End Users, Application Engineers, System Engineers or anyone who is responsible for the design and maintenance of a wireless data network. Additionally, any management personnel who supervise and delegate the design and maintenance assignments for a wireless network will benefit from these courses.

Fundamentals of RF Communications | |

| Instructors will remove the mysteries of RF communications by showing students the fundamentals of RF wireless theory, design, and installation. We will also discuss best practices for industry standard applications including Point-to-Point and Point-to-Multipoint radio systems. Students will also learn about the various types of radio interfaces including protocols and network fundamentals. | |

Lentronics Hardened Optical Networks | |

| Lentronics Hardened Optical Networks product specialists offer a variety of training courses for both SONET and SDH telecommunications standards. Customers can choose from holding training courses at their own physical location, or having their personnel take training at the GE Vernova main office located in Burnaby, just outside of Vancouver, Canada. Courses range from 2 to 5 days in length depending on customer requirements and the depth of training desired. Customized courses can also be provided. | |

Regional Training | |

Regularly scheduled Regional Training courses are offered at selected locations around North America. Contact your factory representative to discuss course offerings. Click here to request more information on regional training courses.

| |

| Training for JungleMUX & TN1U/TN1Ue | |

Factory Training Courses

Instructors will remove the mysteries of RF communications by showing students the fundamentals of RF wireless theory, design, and installation. We will also discuss best practices for industry standard applications including Point-to-Point and Point-to-Multipoint radio systems. Students will also learn about the various types of radio interfaces including protocols and network fundamentals.

Customer Site Training Courses

To increase the number of employees who can benefit from our training, GE Vernova MDS Technical Training offers the option of conducting training courses in person at customer facilities. These on-site courses can be customized to a specific range of topics.