Modular Substation Automation Systems

GE Vernova’s Modular Substation Automation Systems bring together an extensive portfolio of products, services and engineering excellence to deliver the next generation of substation systems for our customers that address the challenges of legacy substation systems.

GE Vernova’s Modular Substation Automation Systems offering includes a wide range of solutions to suit customer’s specific requirements and can be pre-designed, pre-packaged and pre-tested.

Designed with scalability in mind, the systems are also flexible to support several applications including power generation, transmission and distribution, wind and solar collector substations, heavy industries, mining and oil and gas.

Modular Substation Automation Systems

GE Vernova’s Modular Substation Automation Systems bring together an extensive portfolio of products, services and engineering excellence to deliver the next generation of substation systems for our customers that address the challenges of legacy substation systems.

GE Vernova’s Modular Substation Automation Systems offering includes a wide range of solutions to suit customer’s specific requirements and can be pre-designed, pre-packaged and pre-tested.

Designed with scalability in mind, the systems are also flexible to support several applications including power generation, transmission and distribution, wind and solar collector substations, heavy industries, mining and oil and gas.

GE Vernova’s Modular Substation Automation System Offering Summary

GE Vernova’s Modular Substation Automation Systems provide customers with benefits such as improved network reliability, improved service restoration, reduced operation and maintenance costs, and enhanced visibility and control.

| Integrated Protection and Control, Modular Automation System | Integrated Automation System | Modular Protection and Control Systems with or without Process Bus |

|---|---|---|

A pre-engineered, pre-packaged and pre-tested system that delivers:

| A pre-designed, pre-packaged and pre-tested system built on gateways, remote terminals units (RTUs) and communication devices that delivers:

| A fully integrated, modular solution set comprised of:

|

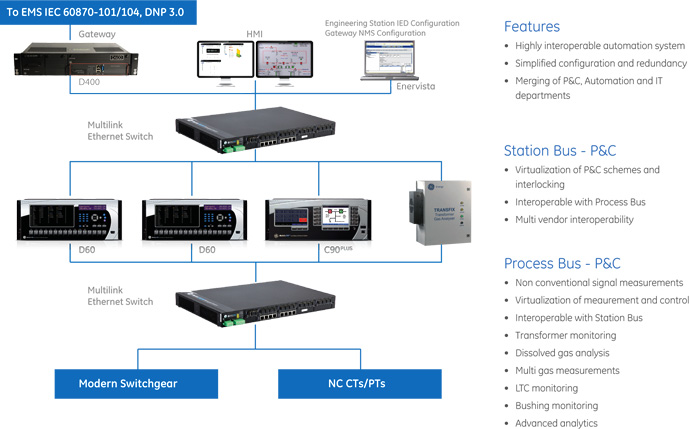

Integrated Protection and Control, Modular Automation System

GE Vernova’s Integrated Protection and Control Modular Automation System is a pre-engineered, pre-packaged and pre-tested system that is:

- Designed using GE Vernova’s modular Multilin UR and URPlus relays connected with Multilin HardFiber Bricks.

- A communication architecture built on industry leading MultiLink Ethernet switches that can deliver higher network availability, redundancy with Parallel Redundancy Protocol (PRP) and high throughput.

- An automation System built on GE Vernova’s cyber secure Multilin D400 gateway delivering IED station bus integration with capabilities to integrate the substation to an enterprise Energy Management or Distribution Management System.

- Cyber security compliant across the entire system design.

Integrated Protection and Control System Capabilities

Key Benefits

- Reduced engineering, testing and maintenance requirements with highly reliable and virtualized P&C schemes

- Increased network communications reliability with built in redundancy and abstracted communication technology in the P&C system

- Advanced cyber security automation complying to NERC® CIP standards and providing advanced substation interlocking and alarm systems

- Improved situational awareness through the advanced Human Machine Interface (HMI)

- Up to 30% reduction in engineering resources, up to 70% reduction in design and construction resources and up to a 40% reduction in project cycle time.

Integrated Automation System

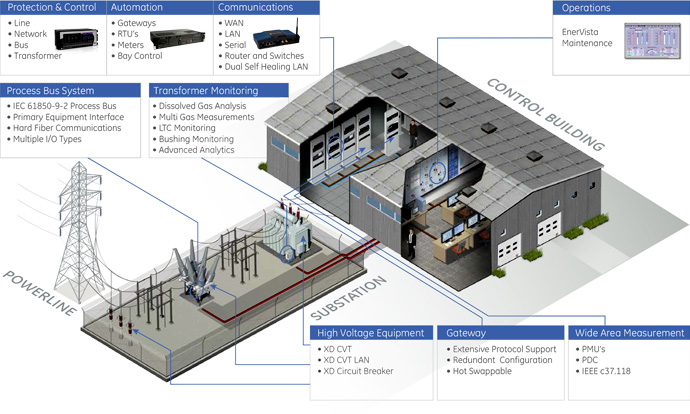

GE Vernova’s Integrated Automation System provides the next generation substation system with a pre-designed, pre-packaged and pre-tested automation system designed for transmission and distribution-type applications in new substation builds and retrofit projects.

Built on industry leading gateways, RTUs and communication products, the Integrated Automation System provides:

- A highly available and reliable network for connecting substation IEDs using MultiLink Ethernet switches.

- Automation gateways that can integrate modern IEDs to legacy IEDs to electromechanical devices for collecting both operational and non operational data.

- Flexible and secure WAN communications utilizing GE Vernova’s MDS industrial wireless devices and Lentronics JungleMUX Multiplexers for SCADA EMS integration as well as teleprotection applications.

- A modern HMI which delivers real time view and control of the substation and IT assets complying to IEC 61850 and other standards.

Integrated Automation System Components

Key Benefits

- Improved service restoration

- Enhanced network visibility and control

- Secure and highly available communications network with PRP support that is simple and easy to configure

- Pre-configured to accommodate legacy systems

- Simplified system alarms and complex substation interlocking throughout the system

- Compliant NERC CIP architecture

Approximately 30% of global transmission and distribution systems around the globe have been automated utilizing a variety of GE Vernova technology, allowing customers to capitalize on GE Vernova’s deep domain knowledge in systems resulting in accelerated implementations and cost savings.

Modular Protection and Control System

GE Vernova's Modular Protection and Control System provides a flexible and fully integrated modular solution set comprised of engineering, design, manufacturing assembly, wiring, testing and commissioning support for protection and control of power system applications. The system is built on an advanced GE Vernova product base and features seamless integration with legacy and multi-vendor devices and systems.

For more information on GE Vernova’s modular Protection and Control system, visit the Packaged Solutions webpage.

Packaged Solutions for a Wide Range of Applications

Generation

Fully integrated sub-system solutions for protection and control of generators with sizes ranging from tens of KWs to hundreds of MWs

Transmission

Pre-designed modular protection, control and automation solutions for transmission system assets such as transmission lines, bus-bars, large transformers and capacitor banks

Distribution

Expandable modular solutions for assets within a distribution substation, e.g. transformers, breakers, cap-banks, and assets outside the 'substation fence', e.g. reclosers

Power Utilization and Automation

A wide variety of modular metering, automation, industrial process protection and control solutions for commercial and industrial customers

Generator Protection and Control Solution

- Leverages advanced GE Vernova protection relays

- Fully integrated, tested packaged solution

- High quality workmanship and accelerated delivery cycles

Advanced Bus Protection and Control Solution

- Pre-designed, configurable advanced protection schemes

- Bus differential protection and control package

- Engineered solutions for custom transmission applications

Pre-designed Distribution Solutions

- Pre-designed modular protection and control solutions for distribution applications such as feeder, transformer and breaker

- Designed for indoor or outdoor applications

- Library of modular designs for common distribution applications

Automation and Industrial Solutions

- Customized RTU solutions for variety of applications

- Supported by large host and IvED protocol libraries

- Fully configured, factory tested solution

GE Vernova’s Professional Services Process

Based on years of experience and several deployments across multiple applications and industries, GE Vernova has developed a Professional Services Process that allows us to partner with our customers for successful grid automation project implementations.

GE Vernova’s Professional Services Process is an approach based on a common set of building blocks, utilized and tailored for each customer’s unique systems requirements. It is a comprehensive process designed to be application-specific.

GE Vernova’s Professional Services Process and Key Activities