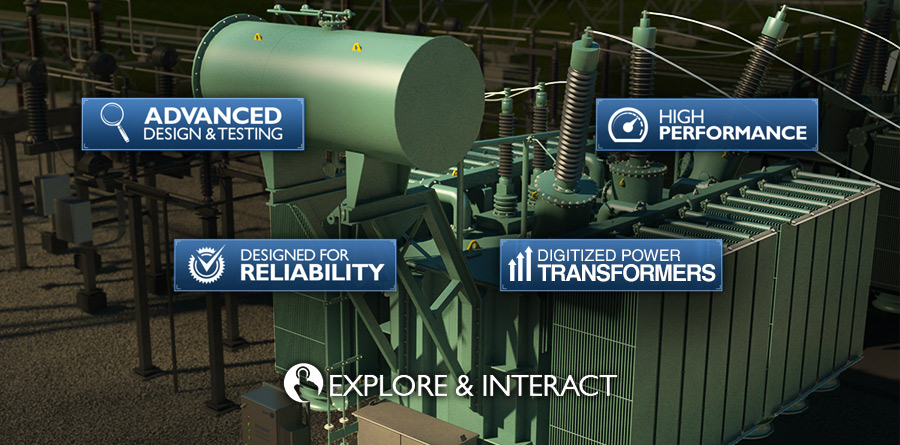

Power Transformers

Low maintenance, high performance, digital and environmental-friendly designs

GE Vernova’s comprehensive suite of power transformers support a wide range of voltage levels with applications in generation, transmission and distribution. GE Vernova offers a wide variety of power transformers from medium to ultra-high voltage (1200 kV AC and ±1100 kV DC) and from small (5 MVA) to very large power ratings (2750 MVA).

Our product lines include conventional, special transmission such as phase-shifting, SVC, HVDC, low maintenance and reactors, as well as green power transformers. GE Vernova’s power transformers provide exceptional performance, quality and reliability with digitized protection and monitoring schemes and advanced design and testing capabilities.

Power Transformers

Low maintenance, high performance, digital and environmental-friendly designs

GE Vernova’s comprehensive suite of power transformers support a wide range of voltage levels with applications in generation, transmission and distribution. GE Vernova offers a wide variety of power transformers from medium to ultra-high voltage (1200 kV AC and ±1100 kV DC) and from small (5 MVA) to very large power ratings (2750 MVA).

Our product lines include conventional, special transmission such as phase-shifting, SVC, HVDC, low maintenance and reactors, as well as green power transformers. GE Vernova’s power transformers provide exceptional performance, quality and reliability with digitized protection and monitoring schemes and advanced design and testing capabilities.

DIGITIZED POWER TRANSFORMERS

- Continuous & intelligent bushing monitoring

- Online gas analysis of up to 7 fault gases plus oxygen & moisture

- Constant temperature monitoring for winding hot spots

- Fast tripping with unrestrained differential element

HIGH PERFORMANCE

- High efficiency cooling system with speed controllable fans

- Minimizing losses & noise level

- Leakage flux control reduce stray losses & hot spots

DESIGNED FOR RELIABILITY

- Design verified with sophisticated validation & analysis software

- High short circuit withstand

- Wide range of options for HV/MV bushings

ADVANCED DESIGN & TESTING

- Extensive testing capabilities with in-house developed design rules & software

- Strong contribution to industry & standardization organizations (i.e: CIGRE & IEEE)

- State-of-the-art software & design analysis tools

Conventional Power Transformers

GE Vernova’s large, medium and small power transformers include equipment and solutions tailored to meet global customer’s needs. GE Vernova utilizes the latest in design, measurement and testing tools to ensure each transformer meets and exceeds the latest industry standards, as well as operational and customer specifications. Our design software includes sophisticated, in-house scientific calculation tools to perform advanced transformer analytics.

The power transformer design optimization, verification and analytical software supports consistent fulfillment of all specified requirements and efficiencies greater than required by 2020 EC Energy Directive, EN 50629 and EN 50588-1. Examples of high efficiency are found in optimized transformer cooling, low air forced cooler noise, advanced core design techniques that reduce no-load loss and no-load noise, and accurate design verification tools.

Key benefits

- Large power transformers up to 1200 kV AC and power ratings up to 1000 MVA

- Small and medium power transformers up to 245 kV and 120 MVA

- The design and rating of tertiary windings and coupling arrangements are adapted to customer’s requirements

- Autotransformers up to 1200 MVA and voltages up to 765 kV Learn more

- Generator step-up transformers up to 1000 MVA Learn more

Autotransformers

Compared with interconnection transformers of equivalent power flow, the autotransformer presents a lighter and more economically optimized solution which is possible whenever the voltage ratio is between 1 and 2. However, autotransformers have non-disconnected windings, meaning there is no galvanic insulation between the interconnected systems.

Characteristically for complex regulation arrangements, autotransformers impose a total mastership of dielectric phenomena. Designs for constant flux regulation at high voltages or booster schemes are part of GE Vernova’s mastery. For many years, GE Vernova been supplying very high rated autotransformers such as single phase up to 500 MVA and very high voltage up to 765 kV for networks all over the world.

Key features:

- Available up to 765 kV

- Designed for constant flux regulation at high voltages and booster schemes

- Advantages include compact footprint, lighter weight and lower losses

Generator Step up Transformers

GE Vernova’s generator step-up (GSU) transformers are designed and manufactured to stringent standards, providing superior performance and long life. They are suitable for nuclear, thermal and hydraulic applications from small to high voltages with power ratings from 5 MVA to 1000 MVA. The step-up transformers have delta-connected LV windings energized by the generator voltage, while star connected HV windings are connected to the transmission lines.

Constantly faced with voltage changes either due to load rejection or switching operations, followed by generator over excitation, the transformer must also maintain the ability to withstand over-loads. The high rated current involved requires absolute control of the magnetic field inside the tank to avoid localized overheating of associated metallic parts. All of these situations are taken into account by GE Vernova during the design process of individual units and are tested with state-of-the-art techniques.

Thanks to our specific know-how coupled with state-of-the-art modeling and design tools, GE Vernova is able to provide solutions that meet unique power requirements with every installation.

Special Power Transformers

Prolec GE taps into state-of-the-art technology and deep domain expertise in insulation structures, thermal requirements and magnetic field distribution applications, to provide power transformers with exceptional performance, quality and reliability.

PHASE-SHIFTING TRANSFORMERS

As high voltage network systems are connected with each other at several points, the necessity of controlling the flow of energy increases. Classical voltage regulation without phase shifting is no longer sufficient for these situations. GE Vernova’s phase-shifting transformers, rated up to 2750 MVA, are available as single core units with independent phase angle and voltage regulation, and as dual core for higher power and voltages. Quadrature boosters provide an economical solution when limited phase-shifting angles are required with voltage variations.

TRANSFORMERS FOR SVC

GE Vernova’s Static Var Compensator (SVC) systems can help grid operators to gain accurate control of reactive network power, maximize power transfer capability, improve steady-state and dynamic stability within the grid. GE Vernova’s SVC power transformers are custom designed and built to handle harmonic loading and a wide voltage variation. These can be configured as three phase units or a bank of single phase units. The function of the power transformers is to connect the medium voltage equipment to the high voltage transmission grid.

INDUSTRIAL TRANSFORMERS

GE Vernova’s industrial specialized transformers portfolio includes a wide range of rectifier transformers for the electrolysis process of metal or chemical industries, as well as AC or DC Electrical Arc Furnace (EAF) transformers. With expertise in products up to the highest ratings in the world, GE Vernova’s references include rectifier transformer combinations above 80 kA DC current ratings and EAF transformers up to 300 MVA.

LOW MAINTENANCE TRANSFORMERS

Hermetically sealed power transformers without oil conservator are GE Vernova’s field-proven answer to today’s needs. Thanks to the innovative design of the radiators, the oil expansion vessel is not needed and thus the oil is prevented from coming into contact with ambient humidity. Service life is also increased with the use of a vacuum-switch on-load tap-changer (OLTC) that eliminates contact erosion. With minimal oil and OLTC aging rate, the Hermetik does not require any particular maintenance or work over its service life, speeding up the return on your investment.

OIL-IMMERSED REACTORS

GE Vernova’s environmental-friendly, long-life, maintenance-free reactors enhance system performance and power quality from transmission and distribution to industrials, improving network operational efficiency. This results in considerable savings for customers and reduces the environmental impact of their operations.

HVDC CONVERTER TRANSFORMERS

GE Vernova offers a wide range of dedicated High Voltage Direct Current (HVDC) systems that enable efficient and reliable transmission of energy over long distances and interconnect networks with different characteristics and frequencies. GE Vernova is an expert in the design and manufacture of HVDC converter transformers with sophisticated insulation and thermal structure. Ratings include 500 MVA and voltage levels up to 800 kV.

Green Transformers

GE Vernova has developed a wide offering of green solutions for power transformers ranging from 10 to 500 MVA and ratings up to 550 kV. Our environmentally-friendly solutions are aimed at meeting the major energy challenges of today and tomorrow: energy efficiency, market efficiency, grid reliability, enhanced overload capability, low loss, low noise and environmental concerns.

GE Vernova’s green power transformers offer significant environmental benefits, including better product performance, across the phases of the product life cycle:

- Reduced consumption of natural resources during manufacturing

- Lower CO2 emissions, limitation of environmental risk, noise reduction, space savings and energy efficiency during operation

- Recycling capabilities of products at the end of their life

Key benefits

- Range of green eco-efficient power transformers, from 10 to 500 MVA and up to 550 kV

- Prevention of pollution and increased safety by using natural ester insulation liquid

- Innovative technologies to reduce acoustic energy transferred and optimized design of the active part

- Optimized low loss levels

- Innovative technology to reduce noise level

- Reduced maintenance cost, extended life time and increased overload with hermetically-sealed tank design, equipped with patented expandable radiators and vacuum type tap changer

- On-line condition monitoring system

- State-of-the-art factories around the world

VG-100 Fluid – Vegetable Oil for Electrical Transformers

VG-100® is a biodegradable dielectric fluid developed by Prolec GE, with patents granted for its application in electrical transformers. VG-100 has been satisfactorily used in more than 500 units since its introduction in 2009, and is an excellent alternative to mineral oil for use in new transformers and retrofill applications.

View the brochure