PowerNode Load Shedding

Industrial load shedding enables facility electrical system stability in critical situations such as a sudden loss of available power, to balance load power consumption due to grid power restrictions (Demand Response) or to limit power consumption during peak hours (Peak Shaving).

PowerNode offers a variety of applications that can be adapted to existing or new installations including:

PowerNode Load Shedding

Industrial load shedding enables facility electrical system stability in critical situations such as a sudden loss of available power, to balance load power consumption due to grid power restrictions (Demand Response) or to limit power consumption during peak hours (Peak Shaving).

PowerNode offers a variety of applications that can be adapted to existing or new installations including:

Facility Challenges

Industrial facilities often have multiple sources of power to support their operational needs which can include on site generation as well as power being supplied by the utility. When a plant experiences a loss of one of these power sources, the remaining power generation may not be able to support the existing plant loading and result in an unplanned shutdown. These unplanned shutdowns can have a very significant impact in the plant’s productivity and availability, causing significant losses in revenue when they occur.

Additionally, economical and/or grid compliance can require a facility to shed loads. Participating in Demand Response scenarios or limiting the Peak energy consumption of a facility can greatly impact the financial impact of plant operations.

GE Vernova’s PowerNode: Load Shedding Solution

GE Vernova’s PowerNode: Load Shedding (LS) solution provides a platform with real-time operation capabilities to combine all load shedding functions together with advanced monitoring and control.

Fast Load Shedding:

Subcycle (<15ms) remedial action scheme that prevents the electrical system from collapsing when there is a lack of available power due to a sudden loss of power sources in the industrial facility.

Industrial Facility Load Shedding Solution

Electrical Stability Load Shedding:

Customized load shedding solutions based on power, frequency or voltage moving out of acceptable limits. Scenarios executed by the Load Shedding controller can operate with times from 100ms to several seconds after the power instability was detected by the protection relays.

Demand Response:

Due to the increasing instability of the grid caused by renewable integration, grid operators are increasing the pressure on industrial consumers to participate in load demand control scenarios. Demand Response solutions can help facilities generate revenue through market participation as well as comply with grid requirements.

Peak Shaving:

Focuses on intelligently limiting utility peak power consumption to reduce a facilities electricity bill.

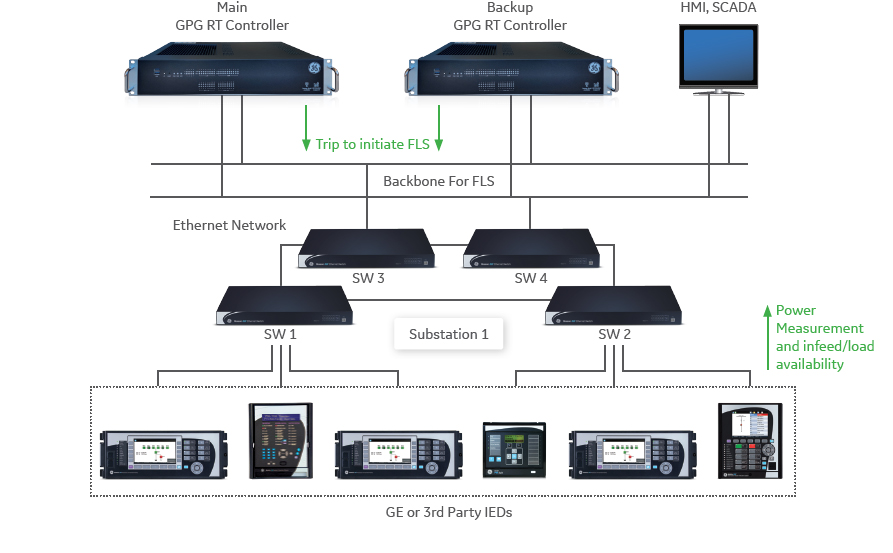

GPG RT Controller

GPG RT Controller

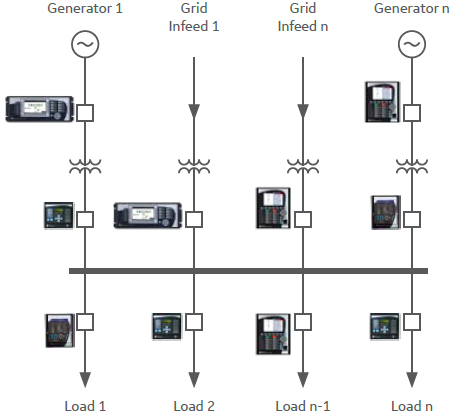

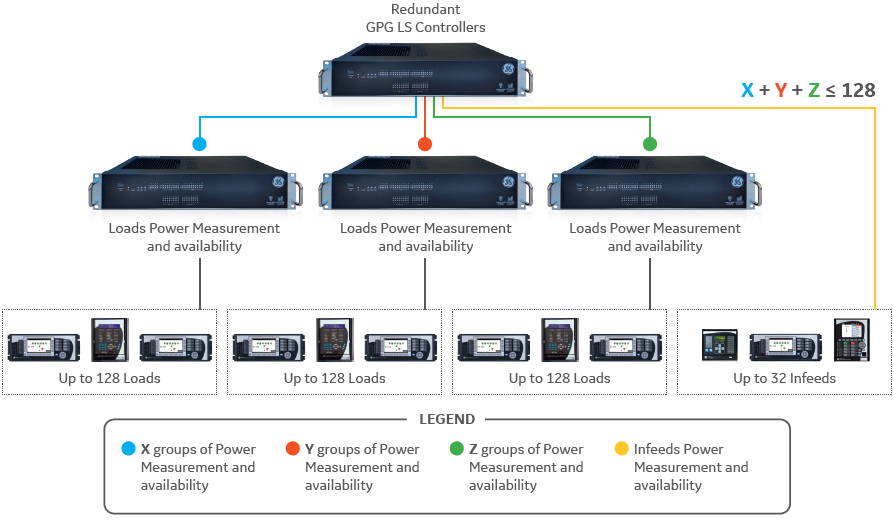

P&C relays send load/infeed power measurements and their availability to the Load Shedding controller using IEC 61850 GOOSE messages or other legacy protocols.

GE Vernova’s Load Shedding controller receives notification of a loss of an infeed from the P&C relays using IEC 61850 GOOSE messages.

Based on the priorities set by the operator, the FLS algorithms will dynamically shed only the loads groups needed to match the amount of generation lost.

GE Vernova’s proven algorithms have been verified and validated to operate in under 15ms from the time the loss of infeed has been detected.

For additional reliability, redundant Load Shedding controllers can be used.

GE Vernova’s Load Shedding solution supports:

- 128 Load Priorities

- 32 Infeeds

- 128 Load Groups

- 1000+ Loads

Aggregator IEDs are used to group Loads when more than 128 loads are present in the installation.

Aggregator IEDs receive availability and power measures from multiple loads and group them in one of the 128 Load Groups.

The GPG RT Controller is a real-time controller that hosts GE Vernova’s Load Shedding solution and other power system control applications. The GPG RT Controller has been designed to be compliant with IEC 61850-3, which is an international hardware standard for communication networks and systems in power substations. Supporting international cybersecurity standard, the GPG RT Controller is the backbone of GE Vernova’s industrial power solutions that ensure reliable and secure operation for improving the reliability of industrial power networks.

Hardware Specifications

- Certification: IEC 61850-3, IEEE 1613, CE, FCC Class A, UL, CCC

- -20 to 70 degree Celsius operating temperature

- Mounting: 2U/19” Rack mount

- System Design: Fan-less, with no internal cabling

- OS Support: RTOS VxWorks and Windows Embedded.

- Power Supply: Redundant 100 ~ 240 VAC (47 ~ 63 Hz) DC: 100 ~ 240 VDC DC: 48VDC

- PRP & HSR Ethernet redundancy.

- Two expansion slots to increase serial and Ethernet port types and quantity.

Redundancy

GPG RT Controller offers multiple redundancy modes to align with customer requirements. The GPG redundancy can be set up in one of two different modes:

- Hot-Standby: GPGs arranged in a master and slave configuration

- Hot-Hot: Both GPGs working in parallel

PRP and HSR Ethernet redundancy options are available to support fault tolerant communication architectures.

GPG RT Controller

GPG RT Controller

Supported Protocols

- IEC 61850 Server Ed.1 and Ed.2

- IEC 61850 Client Ed.1 and Ed.2. KEMA Certified

- IEC 61850 GOOSE

- C37.118 and IEC61850-90-5 Synchrophasor Protocol

- IEC 60870-5-101/104 Server/Client. KEMA Certified

- DNP3 Master/Slave RTU and TCP

- SNMP Client

- MQTT

- NTP client. With Redundancy

- Modbus RTU/TCP Master/Slave

- IEC 6070-5-103 Master

- SPA-Bus Master

- OPC DA & AE Server/Client

- OPC UA Server

- EGD Producer

Reduces unplanned downtime impact

- Cost of materials lost in process

- Cost of lost production

- Cost of potential equipment damage

- Cost of environmental impact

Best in class performance

- The fastest operation time in the market: <15ms

Integrates with P&C

- Analog load and generation data transferred through IEC 61850 GOOSE messaging

- Integrates with existing protective relays

- Uses existing Ethernet network

Scalable and flexible

- Can expand from one to thousands of loads

- Dynamic load shed based on plant conditions

- Changes to the load priorities set in seconds from operator’s HMI system

Easy Future Expansions

- Updates / expansion made through device configuration, no additional wiring

Vendor Agnostic

- Can integrate GE Vernova and non-GE Vernova IEDs

Recommended Products & services

Modular Substation Automation Systems

GE Vernova’s Modular Substation Automation Systems bring together an extensive portfolio of products, services and engineering excellence to deliver the next generation of substation systems for our customers that address the challenges of legacy substation systems.

GE Vernova’s Modular Substation Automation Systems offering includes a wide range of solutions to suit customer’s specific requirements and can be pre-designed, pre-packaged and pre-tested.

Modular Substation Automation Systems

GE Vernova’s Modular Substation Automation Systems bring together an extensive portfolio of products, services and engineering excellence to deliver the next generation of substation systems for our customers that address the challenges of legacy substation systems.

GE Vernova’s Modular Substation Automation Systems offering includes a wide range of solutions to suit customer’s specific requirements and can be pre-designed, pre-packaged and pre-tested.

GE Vernova’s Modular Substation Automation System Offering Summary

GE Vernova’s Modular Substation Automation Systems provide customers with benefits such as improved network reliability, improved service restoration, reduced operation and maintenance costs, and enhanced visibility and control.

| Integrated Protection and Control, Modular Automation System | Integrated Automation System | Modular Protection and Control Systems with or without Process Bus |

|---|---|---|

A pre-engineered, pre-packaged and pre-tested system that delivers:

| A pre-designed, pre-packaged and pre-tested system built on gateways, remote terminals units (RTUs) and communication devices that delivers:

| A fully integrated, modular solution set comprised of:

|

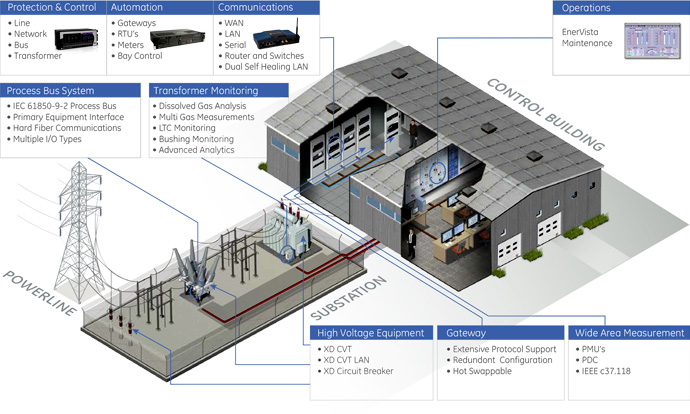

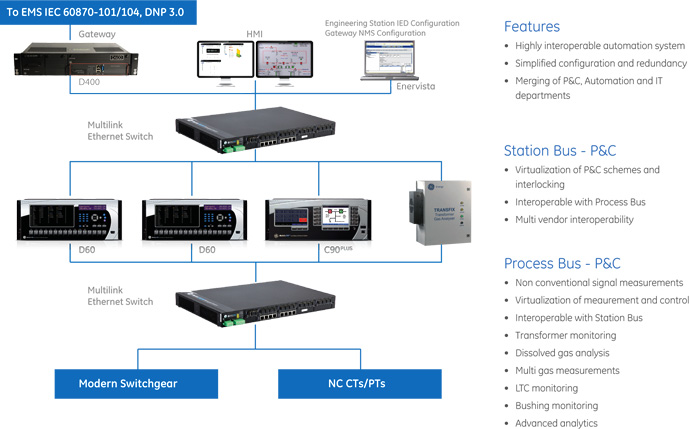

Integrated Protection and Control, Modular Automation System

GE Vernova’s Integrated Protection and Control Modular Automation System is a pre-engineered, pre-packaged and pre-tested system that is:

- Designed using GE Vernova’s modular Multilin UR and URPlus relays connected with Multilin HardFiber Bricks.

- A communication architecture built on industry leading MultiLink Ethernet switches that can deliver higher network availability, redundancy with Parallel Redundancy Protocol (PRP) and high throughput.

- An automation System built on GE Vernova’s cyber secure Multilin D400 gateway delivering IED station bus integration with capabilities to integrate the substation to an enterprise Energy Management or Distribution Management System.

- Cyber security compliant across the entire system design.

Integrated Protection and Control System Capabilities

Key Benefits

- Reduced engineering, testing and maintenance requirements with highly reliable and virtualized P&C schemes

- Increased network communications reliability with built in redundancy and abstracted communication technology in the P&C system

- Advanced cyber security automation complying to NERC® CIP standards and providing advanced substation interlocking and alarm systems

- Improved situational awareness through the advanced Human Machine Interface (HMI)

- Up to 30% reduction in engineering resources, up to 70% reduction in design and construction resources and up to a 40% reduction in project cycle time.

Integrated Automation System

GE Vernova’s Integrated Automation System provides the next generation substation system with a pre-designed, pre-packaged and pre-tested automation system designed for transmission and distribution-type applications in new substation builds and retrofit projects.

Built on industry leading gateways, RTUs and communication products, the Integrated Automation System provides:

- A highly available and reliable network for connecting substation IEDs using MultiLink Ethernet switches.

- Automation gateways that can integrate modern IEDs to legacy IEDs to electromechanical devices for collecting both operational and non operational data.

- Flexible and secure WAN communications utilizing GE Vernova’s MDS industrial wireless devices and Lentronics JungleMUX Multiplexers for SCADA EMS integration as well as teleprotection applications.

- A modern HMI which delivers real time view and control of the substation and IT assets complying to IEC 61850 and other standards.

Integrated Automation System Components

Key Benefits

- Improved service restoration

- Enhanced network visibility and control

- Secure and highly available communications network with PRP support that is simple and easy to configure

- Pre-configured to accommodate legacy systems

- Simplified system alarms and complex substation interlocking throughout the system

- Compliant NERC CIP architecture

Approximately 30% of global transmission and distribution systems around the globe have been automated utilizing a variety of GE Vernova technology, allowing customers to capitalize on GE Vernova’s deep domain knowledge in systems resulting in accelerated implementations and cost savings.

Modular Protection and Control System

GE Vernova's Modular Protection and Control System provides a flexible and fully integrated modular solution set comprised of engineering, design, manufacturing assembly, wiring, testing and commissioning support for protection and control of power system applications. The system is built on an advanced GE Vernova product base and features seamless integration with legacy and multi-vendor devices and systems.

For more information on GE Vernova’s modular Protection and Control system, visit the Packaged Solutions webpage.

Packaged Solutions for a Wide Range of Applications

Generation

Fully integrated sub-system solutions for protection and control of generators with sizes ranging from tens of KWs to hundreds of MWs

Transmission

Pre-designed modular protection, control and automation solutions for transmission system assets such as transmission lines, bus-bars, large transformers and capacitor banks

Distribution

Expandable modular solutions for assets within a distribution substation, e.g. transformers, breakers, cap-banks, and assets outside the 'substation fence', e.g. reclosers

Power Utilization and Automation

A wide variety of modular metering, automation, industrial process protection and control solutions for commercial and industrial customers

Generator Protection and Control Solution

- Leverages advanced GE Vernova protection relays

- Fully integrated, tested packaged solution

- High quality workmanship and accelerated delivery cycles

Advanced Bus Protection and Control Solution

- Pre-designed, configurable advanced protection schemes

- Bus differential protection and control package

- Engineered solutions for custom transmission applications

Pre-designed Distribution Solutions

- Pre-designed modular protection and control solutions for distribution applications such as feeder, transformer and breaker

- Designed for indoor or outdoor applications

- Library of modular designs for common distribution applications

Automation and Industrial Solutions

- Customized RTU solutions for variety of applications

- Supported by large host and IvED protocol libraries

- Fully configured, factory tested solution

GE Vernova’s Professional Services Process

Based on years of experience and several deployments across multiple applications and industries, GE Vernova has developed a Professional Services Process that allows us to partner with our customers for successful grid automation project implementations.

GE Vernova’s Professional Services Process is an approach based on a common set of building blocks, utilized and tailored for each customer’s unique systems requirements. It is a comprehensive process designed to be application-specific.

GE Vernova’s Professional Services Process and Key Activities

Recommended Products & services

MID Digital Distribution System Family

The DDS family of devices provide economical protection, control, metering and monitoring functionality to electrical utilities and industrial customers.

The DDS family substitute with one box a complete set of discrete devices such as electromechanical relays, meters, annunciator panels, pushbuttons, transducer, auxiliary relays, and mimic drawings.

MID Digital Distribution System Family

The DDS family of devices provide economical protection, control, metering and monitoring functionality to electrical utilities and industrial customers.

The DDS family substitute with one box a complete set of discrete devices such as electromechanical relays, meters, annunciator panels, pushbuttons, transducer, auxiliary relays, and mimic drawings.

Recommended Products & services

MIC Digital Overcurrent Relay - Legacy

Manufacturing for this product has been discontinued. As an alternative, please refer to F35 or DIAC/DIFC/DSFC relays.

MIC Digital Overcurrent Relay - Legacy

Manufacturing for this product has been discontinued. As an alternative, please refer to F35 or DIAC/DIFC/DSFC relays.

Recommended Products & services

MIB High Impedance Busbar Differential Relay

Manufacturing for this product has been discontinued.

MIB High Impedance Busbar Differential Relay

Manufacturing for this product has been discontinued.

Recommended Products & services

MGC Digital Generator Protection Relay

The MGC1000 are microprocessor based, digital type, generator protection relays which provide thermal protection for three phase generators, phase fault, ground fault, and unbalanced current protection.

Applications

- Small generators

Protection & Control

- Unbalance or current reversal

- Thermal protection

MGC Digital Generator Protection Relay

The MGC1000 are microprocessor based, digital type, generator protection relays which provide thermal protection for three phase generators, phase fault, ground fault, and unbalanced current protection.

Applications

- Small generators

Protection & Control

- Unbalance or current reversal

- Thermal protection

Recommended Products & services

MFF Digital Frequency Relay - Legacy

Manufacturing for MFF has been discontinued.

MFF relays are microprocessor based relays that provide protection against frequency variations in AC systems.

Applications

- AC systems

Protection and Control

- Under and overfrequency

MFF Digital Frequency Relay - Legacy

Manufacturing for MFF has been discontinued.

MFF relays are microprocessor based relays that provide protection against frequency variations in AC systems.

Applications

- AC systems

Protection and Control

- Under and overfrequency

Recommended Products & services

M Family Modular Microprocessor Relays - Legacy

Manufacturing for these products have been discontinued

The M Family is a new generation of modular microprocessor protective relays based on a common platform. The M Family offers a competitive solution that combines protection, monitoring, widely accepted communications standards, and flexible configuration tools for many applications. Each product within the M Family may be used as a stand alone unit or as a component of an automated substation or industrial protection and control system.

M Family Modular Microprocessor Relays - Legacy

Manufacturing for these products have been discontinued

The M Family is a new generation of modular microprocessor protective relays based on a common platform. The M Family offers a competitive solution that combines protection, monitoring, widely accepted communications standards, and flexible configuration tools for many applications. Each product within the M Family may be used as a stand alone unit or as a component of an automated substation or industrial protection and control system.

Recommended Products & services

Meter Enclosures

Pre-wired & Configured Metering Solution

Expanding existing switchgear or installing new metering capability can be challenging due to space limitations, downtime and installation and equipment costs. GE Vernova’s Multilin™ Meter Enclosure is a pre-wired configured, economical solution for both retrofit expansions and small scale meter installations that allows the expansion of existing switchgear capability without expensive and time-consuming design.

Meter Enclosures

Pre-wired & Configured Metering Solution

Expanding existing switchgear or installing new metering capability can be challenging due to space limitations, downtime and installation and equipment costs. GE Vernova’s Multilin™ Meter Enclosure is a pre-wired configured, economical solution for both retrofit expansions and small scale meter installations that allows the expansion of existing switchgear capability without expensive and time-consuming design.

Meter Enclosure Assembly

The installation of GE Vernova’s Multilin Meter Enclosure provides customers with a simple, easy to install solution that adds advanced metering capabilities while minimizing system downtime.

The Multilin Meter Enclosure is UL/cUL certified and NEMA 1 rated, making it ideal for indoor environments. It is provided in two voltage configurations (120-240V and 277V) to ensure compatibility with existing systems.

Each meter enclosure is pre-wired and configured with an EPM meter, voltage fuses, shorting block for current transformers and a control power transformer (for 277V power systems), eliminating field wiring and installation issues.

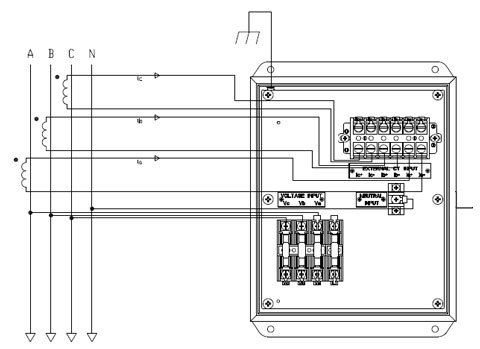

Typical Wiring

Wye Wiring for 120V Model

Wye Wiring for 120V Model

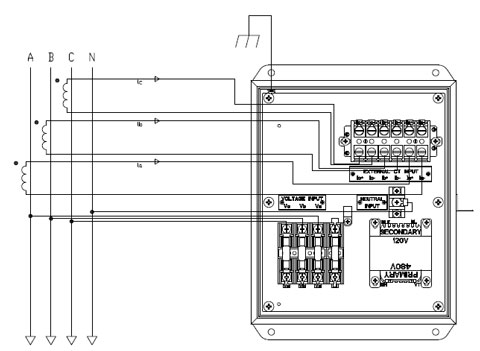

Wye Wiring for 277V Model

Wye Wiring for 277V Model

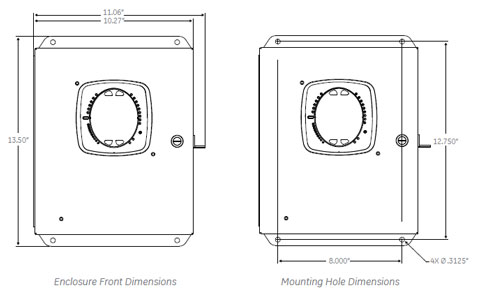

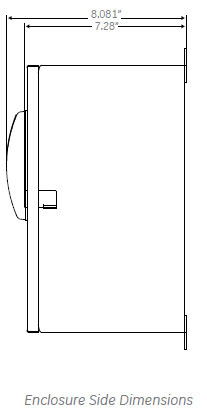

Dimensions

Recommended Products & services

Multilin 469 - Legacy

Motor Protection System

Manufacturing for 469 has been discontinued. As an alternative, please refer to the 859 or 869 relays.

Multilin 469 - Legacy

Motor Protection System

Manufacturing for 469 has been discontinued. As an alternative, please refer to the 859 or 869 relays.

Key Features

- Thermal model biased with RTD and negative sequence current feedback

- Start supervision and inhibit

- Mechanical jam

- Voltage compensated acceleration

- Undervoltage, overvoltage

- Underfrequency

- Stator differential protection

- Thermal overload

- Overtemperature protection

- Phase and ground overcurrent

- Current unbalance

- Power elements

- Torque protection

- Dual overload curves for 2 speed motors

- Reduced voltage starting control

Protection & Control

The 469 is a digital motor protection system designed to protect and manage medium and large motors and driven equipment. It contains a full range of selectively enabled, self contained protection and control elements as detailed in the Functional Block Diagram and Features table.

Key Features

- A, V, W, var, VA, PF, Hz, Wh, varh, demand

- Torque, temperature (12 RTDs)

- Event recorder

- Oscillography & Data Logger (trending)

- Statistical information & learned motor data

Monitoring & Metering

The 469 includes high accuracy metering and recording for all AC signals. Voltage,current, RTD and power metering are built into the relay as a standard feature.

Metering

The following system values are accurately metered and displayed: Phase, differential and ground currents, average current, motor load, current unbalance. Phase-to-ground and Phase-to-phase voltages, average phase voltage, system frequency. Real, reactive, apparent power, power factor, watthours, varhours, torque Current and power demand. Analog inputs and RTD temperatures. Thermal capacity used, lockout times, motor speed

Monitoring

The 469 is equipped with monitoring tools to capture data. The following information is presented in a suitable format.

Event Recorder

The event recorder stores motor and system information with a date and time stamp each time a system event occurs. Up to 256 events are recorded.

Oscillography

The 469 records up to 128 cycles with 12 samples per cycle of waveform data for 10 waveforms (Ia, Ib, Ic, Ig, Diffa, Diffb, Diffc, Va, Vb, Vc) each time a trip occurs. The record is date and time stamped.

Advanced Motor Diagnostics

The Multilin 469 provides advanced motor diagnostics including a broken rotor bar detection function. The broken rotor bar detection is a condition maintenance function that continuously monitors the motor’s health while in operation. The advanced Motor Current Signature Analysis (MCSA) continuously analyzes the motor current signature and based on preset algorithms will determine when a broken rotor bar is present in the motor.

View motor status using digital inputs, analog inputs and RTD inputs

View motor status using digital inputs, analog inputs and RTD inputs

Key Features

- Multiple Ports - 10baseT Ethernet, RS485, RS232, RS422, DeviceNet

Multiple Protocols - Modbus RTU, Modbus TCP/IP, DeviceNet

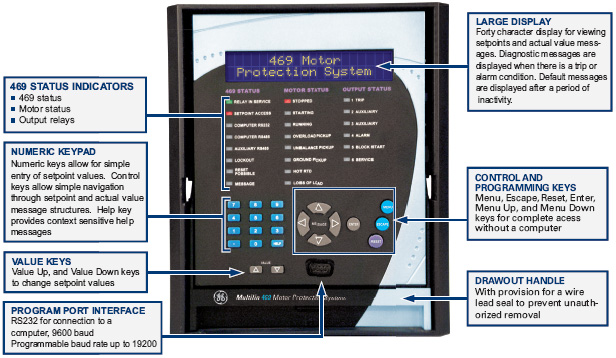

Front Panel

EnerVista™ Software

The EnerVista™ Suite is an industry leading set of software programs that will simplify every aspect of using the 469 relay. Tools to monitor the status of your motor, maintain your relay, and integrate information measured by the 469 into HMI or SCADA monitoring systems are available. Also provided are the utilities to analyze the cause of faults and system disturbances using the powerful Waveform and Sequence of Event viewers that come with the 469 Setup Software that is included with each relay. Learn More

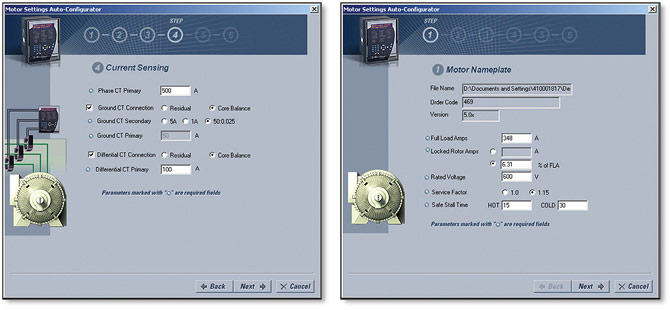

Create complete settings files for your SR469 in 6 simple steps using the Motor Settings Auto-Configurator.

Create complete settings files for your SR469 in 6 simple steps using the Motor Settings Auto-Configurator.

8 Series Retrofit Kit

Retrofit Existing SR 469 Devices to the Multilin 869 in Minutes

Traditionally, retrofitting an existing relay has been a challenging, time consuming task often requiring re-engineering, new drawings, panel modifications, re-wiring and re-testing.

The 8 Series Retrofit Kit provides a quick, 3-step solution to upgrade previously installed SR 469 relays. With the new 8 Series Retrofit Kit users are able to install the 869 Motor Protection System without modifying existing cutouts and wiring, and without any drawing changes or re-engineering time.

Easy 3-Step Process to Upgrade in as Fast as 21 Minutes

EnerVista 8 Series Setup Software provides automated setting file conversion. Once completed, a graphical report is provided to verify and call out any settings that need attention.

Simply remove the terminal blocks and then remove the SR chassis from the panel. No need to disconnect any of the field wiring.

Insert the new 8 Series Retrofit chassis into the switchgear and simply plug-in the old terminal blocks - there is no need to make any cut-out modifications or push and pull cables.