KITZ10x

Interfaces

Sales of the following KITZ models have been discontinued:

KITZ10x

Interfaces

Sales of the following KITZ models have been discontinued:

Recommended Products & services

KAVS - legacy

Check Synchronising Relay

Manufacturing for KAVS has been discontinued. As an alternative, please refer to P94V.

KAVS is a stand-alone synchronism check relay that can be applied on all power systems from distribution to transmission voltages. It is user-friendly and flexible in its operating logic.

KAVS - legacy

Check Synchronising Relay

Manufacturing for KAVS has been discontinued. As an alternative, please refer to P94V.

KAVS is a stand-alone synchronism check relay that can be applied on all power systems from distribution to transmission voltages. It is user-friendly and flexible in its operating logic.

Recommended Products & services

KAVR Series - Legacy

Compact, Multi-shot Autoreclose Relay

Manufacturing for KAVR has been discontinued. As an alternative, please refer to P94V.

It is a compact and simple solution for single or 3-phase reclosing as the first shot. Applicable to all power systems, these relays are user-friendly and enhanced with flexible operating logic.

KAVR Series - Legacy

Compact, Multi-shot Autoreclose Relay

Manufacturing for KAVR has been discontinued. As an alternative, please refer to P94V.

It is a compact and simple solution for single or 3-phase reclosing as the first shot. Applicable to all power systems, these relays are user-friendly and enhanced with flexible operating logic.

Recommended Products & services

Integrated Substation Control System

Next generation substation control and automation

|

Integrated Substation Control System

Next generation substation control and automation

|

Recommended Products & services

IJD Percentage Differential Relay - Legacy

Manufacturing for IJD has been discontinued.

IJD Percentage Differential Relay - Legacy

Manufacturing for IJD has been discontinued.

Recommended Products & services

IJC Current Balance Relay

The Type IJC51E relays are used for the protection of lines and of three- phase machines, especially motors and synchronous converters against damage that is caused by phase- unbalancing and single-phase operation.

IJC Current Balance Relay

The Type IJC51E relays are used for the protection of lines and of three- phase machines, especially motors and synchronous converters against damage that is caused by phase- unbalancing and single-phase operation.

Recommended Products & services

IFCS TOC/Voltage Control Relay - Legacy

Manufacturing for IFCS has been discontinued.

IFCS TOC/Voltage Control Relay - Legacy

Manufacturing for IFCS has been discontinued.

Recommended Products & services

ICW Power Directional Protection Relay

Manufacturing for ICW has been discontinued. As an alternative, please refer to P14D.

ICW Power Directional Protection Relay

Manufacturing for ICW has been discontinued. As an alternative, please refer to P14D.

Recommended Products & services

ICR Phase Sequence and Undervoltage

Manufacturing for this product has been discontinued. As an alternative, please refer to the P94V relays.

ICR Phase Sequence and Undervoltage

Manufacturing for this product has been discontinued. As an alternative, please refer to the P94V relays.

Recommended Products & services

PowerNode: Motor Health Management

Electrical machines play a vital role for the modern industrial world. The impact of unplanned downtime due to breakage of these electrical motors is estimated to be more than $30 billion USD1 each year.

With more than 100 years of engineering experience with motors, generators, and control equipment, GE Vernova brings physics-based analytics and advanced machine learning algorithms to detect evolving faults within electrical motors and helps identify future issues to support customers with avoiding failures and resolving faults in advance.

PowerNode: Motor Health Management

Electrical machines play a vital role for the modern industrial world. The impact of unplanned downtime due to breakage of these electrical motors is estimated to be more than $30 billion USD1 each year.

With more than 100 years of engineering experience with motors, generators, and control equipment, GE Vernova brings physics-based analytics and advanced machine learning algorithms to detect evolving faults within electrical motors and helps identify future issues to support customers with avoiding failures and resolving faults in advance.

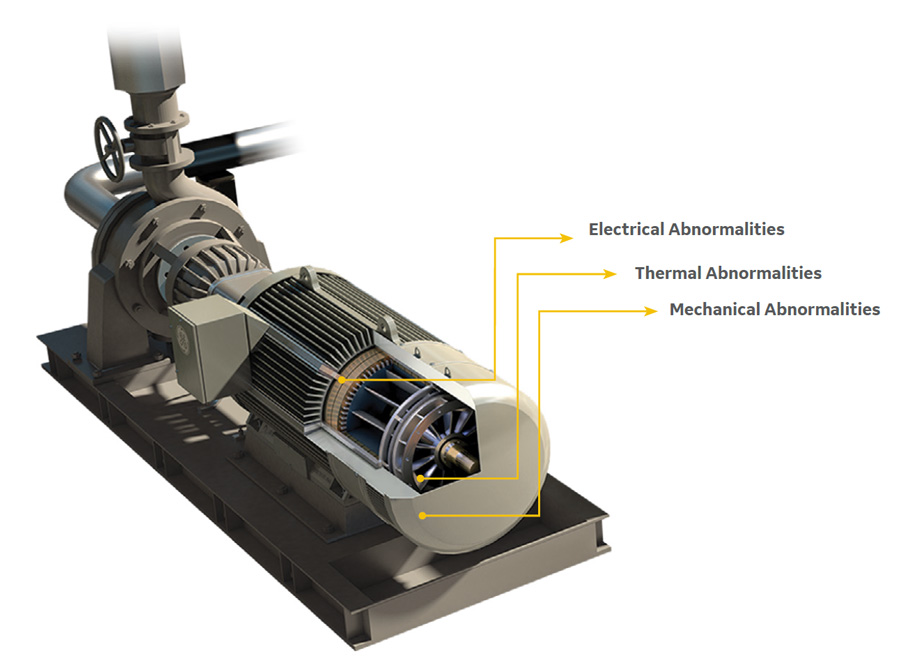

Facility Challenges

Unexpected motor failures decrease plant throughput, increase plant downtime, and can decrease production quality. Current solutions involving scheduled preventive maintenance or sensor-based condition monitoring are expensive.

PowerNode: Motor Health Management

GE Vernova’s Motor Health Management increases uptime and reduces OPEX by implementing prognostics-based equipment insights based on data provided by existing protection relays and meters. No additional sensors are needed.

Our on-site and cloud-based monitoring elements monitor equipment and provide an Equipment Health Dashboard with the remote connectivity and accessibility that enables this connection.

Motor Health Management Managed Services provides detailed insights into alarms and anomalies. Our team of experienced data analysts, subject matter experts and service engineers will provide recommendations for action when an incipient motor fault is detected.

PowerNode: Motor Health Management uses Electrical Signature Analysis (ESA) and machine learning (ML) to predict failures.

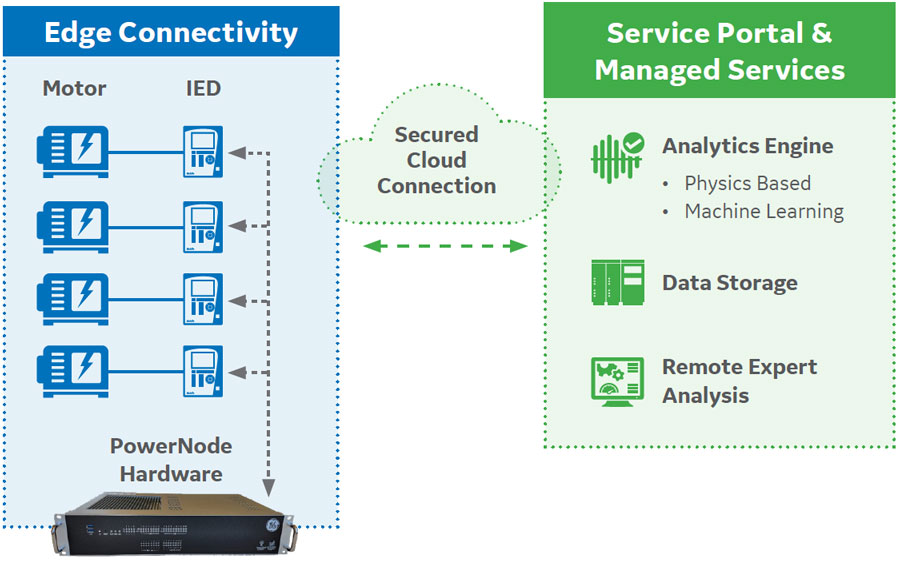

PowerNode: Motor Health Management

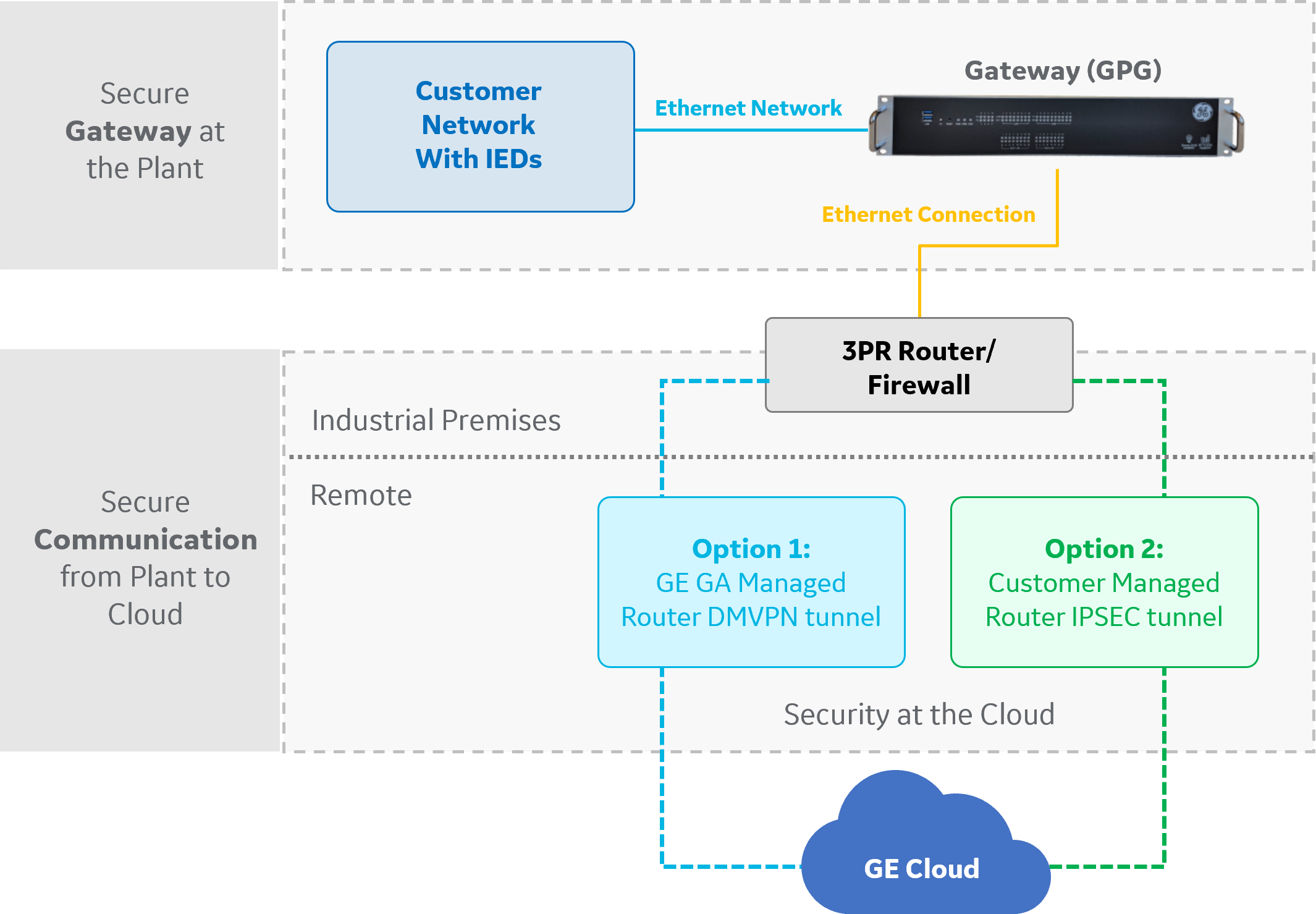

Architecture is as follows:

Edge Connectivity

The GPG Controller located at the industrial premises automatically triggers periodic oscillographies in the motor IEDs if the motor is running. Additional data (temperatures, vibration, electrical data) can also be automatically retrieved if available.

Oscillographies are transferred to the Service Portal through a secure remote connection.

PowerNode: Motor Health Management supports GE Vernova and non-GE Vernova IEDs. For non-GE Vernova IEDs, an evaluation will need to be carried out.

Service Portal

Motor data received from the industrial site is processed and stored in the Service Portal infrastructure.

When a potential fault is detected, the analytics engine automatically opens a case to be reviewed by our managed services team.

The Service Portal also provides a web interface to customers and the managed services team where they can see the asset status overview and details for each monitored asset.

Managed Services

The managed services center receives all potential failures detected by the service portal. A team of experts validates the data, provides recommendations to address the detected problem(s), and supports the site maintenance team.

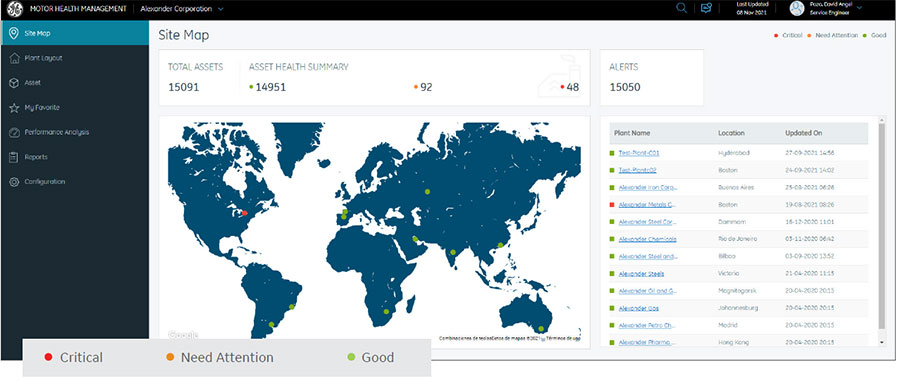

PowerNode: MHM Service Portal Web Interface

GE Vernova’s PowerNode Motor Health Management uses a cloud-based application to store and display data for analytics and monitoring.

Site Map

Overview of the location of all monitored sites and assets of a company. Locations of an asset with potential issues will be highlighted in orange or red.

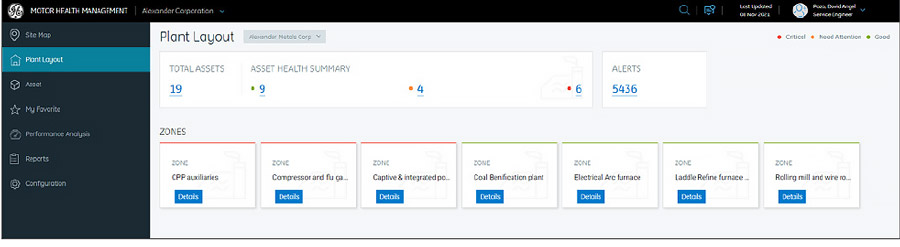

Plant Layout

View the status of an asset by navigating to a specific zone. Assets can be organized into four hierarchical levels for easy access.

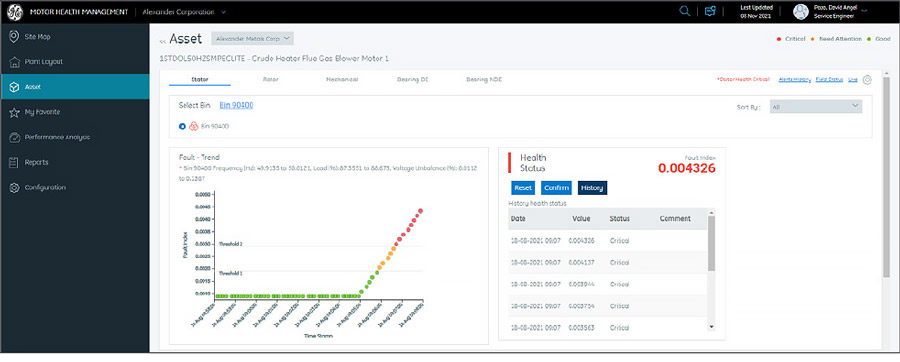

Asset Details

View current and historical data for each asset and failure type to validate a potential motor failure.

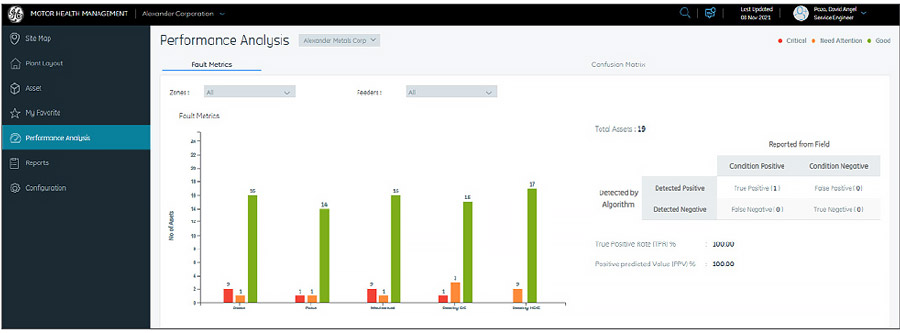

Performance Analytics

Monitor the performance of your assets with a set of dashboards that display the status of the assets by failure type, and a confusion matrix that displays the failure detection accuracy.

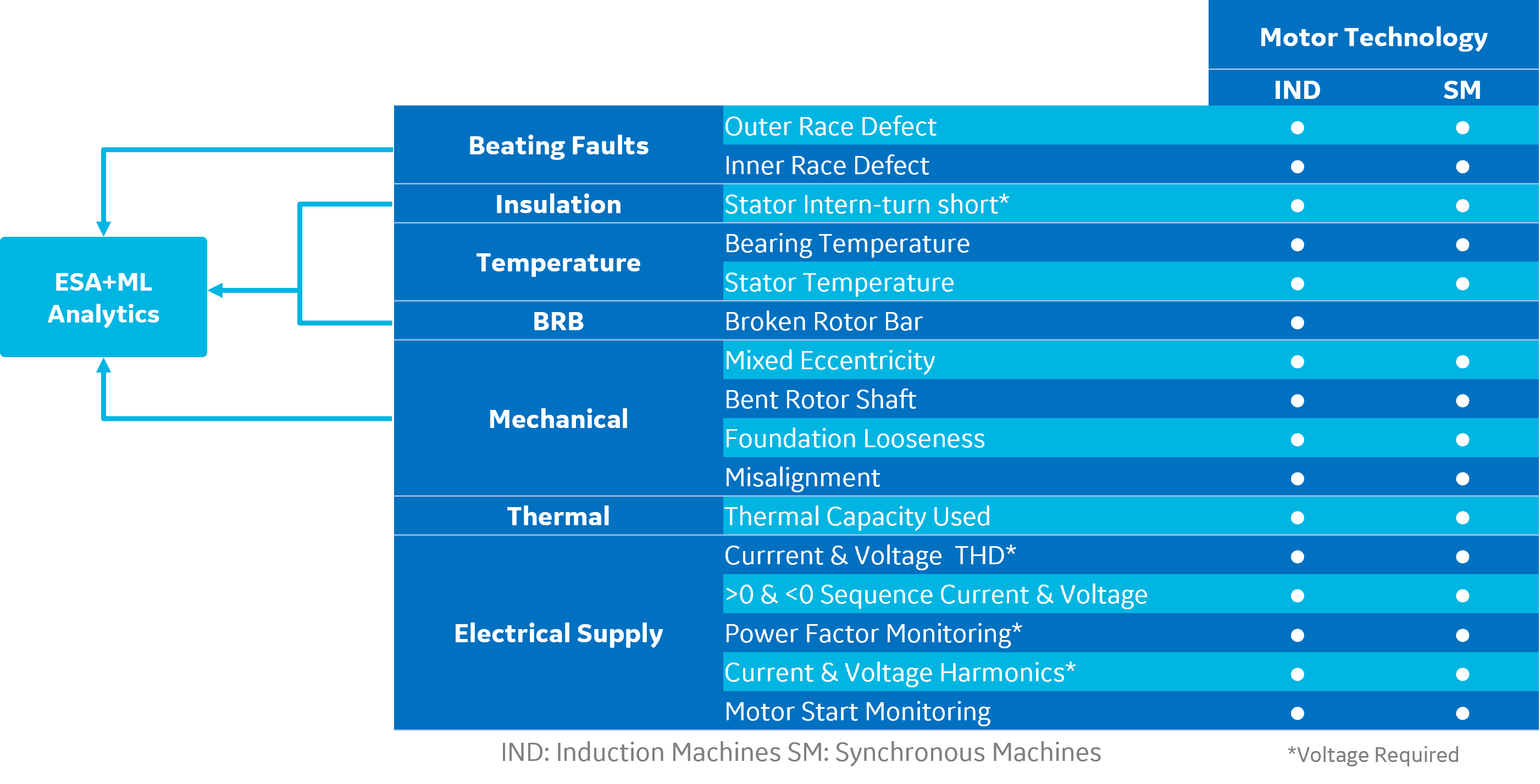

List of Failure Modes

Electrical Signature Analysis (ESA)

- Used to detect various failure modes in a rotating machine by analyzing stator current and voltage signals.

- ESA systems rely upon Fast Fourier Transformer (FFT) analysis, much like vibration analysis.

- ESA fault detection algorithm uses FFT computation of the current signal to detect fault conditions at vibration frequencies related to the corresponding fault condition and computes peak magnitudes with respect to the baseline peak magnitudes (healthy mode of the motor without misalignment).

Machine Learning (ML)

Being part of artificial intelligence, ML algorithms can improve automatically through experience and using data.

GE Vernova’s ML algorithms can automatically detect and classify healthy and unhealthy motor operating conditions (unsupervised clustering).

The algorithms consider multiple parameters derived from the current and voltage readings (frequency, power, speed, rate-of-change, etc.) to increase accuracy of pure ESA analytics.

Secure Gateway at the Plant

- Secured data transfer between IEDs and gateway through standard communication protocols

- Malware protection software, white-listing, and hardening are all implemented

Secure Communication from Plant to Cloud using 3rd Party Rail (3PR)

- All external communications between the WAN router and the GE Vernova data repository are secured using encrypted tunnels. No control system or management ports will be exposed on the outside interface of the WAN router.

- Strong encryption standards to protect the privacy of the communication between the plant and GE Vernova over public networks.

- Inspect inbound/outbound traffic at the edge of the GE Vernova network.

Security at the Cloud

- All the endpoints of the cloud are secured by proper authentications and firewall implementations.

- The data files that are uploaded from the GPG are stored in a folder that is exclusively assigned to a customer. Access to this folder is given only to designated users through appropriate authentication.

Managed Services

The managed services provided by GE Vernova are the core value of Motor Health Management. These services save the customer the unnecessary pain of being exposed to the analytic algorithms while they are still in the process of being fine-tuned, thus avoiding unnecessary mis-operations. They also provide recommendations with regards to the detected failures in the form of prescriptive analytics.

The Managed Services team performs three main actions:

- Service 1:Review and validate the incipient failure of the motor. Prepare and send recommendations of actions to be taken by the site maintenance team to address the problem.

- Service 2:Support the site maintenance team to investigate and correct the problem.

- Service 3:If failures are missed or incorrectly detected, the managed services team performs an investigation and performs modifications of asset parameters and/or performs enhancements to the failure detection algorithms to increase failure detectability.

Electrical motors operate under different load conditions depending on the application. A continuous improvement process can adapt failure detection to your specific operating conditions.

Reduce unplanned downtime

PowerNode: Motor Health Management solution uses advanced diagnostics and prognostics to ensure you can plan your actions before the asset fails, avoid unplanned downtime, and reduce O&M costs.

Make the most of your IEDs

No additional sensors are required. The system uses protection and control relay data and existing communication infrastructure to minimize cost of deployment and installation impact.

Leverage GE Vernova's managed services

Our managed services team will accurately interpret the results and guide you in making the right decisions.