OTEF

Oil-Insulated Voltage Transformers (VT) up to 420 kV

GE Vernova manufactures a complete range of high voltage oil-filled voltage transformers (VTs). The OTEF is a tank-type potential transformer with post insulator. Thousands voltage transformers are in service worldwide, in all types of climates and under the most severe conditions.

OTEF

Oil-Insulated Voltage Transformers (VT) up to 420 kV

GE Vernova manufactures a complete range of high voltage oil-filled voltage transformers (VTs). The OTEF is a tank-type potential transformer with post insulator. Thousands voltage transformers are in service worldwide, in all types of climates and under the most severe conditions.

Recommended Products & services

OSKF

Oil-Insulated Current Transformers (CT) up to 800 kV

GE Vernova’s OSKF have been designed for a 30 year lifetime and, thanks to the profound technical concepts, many well out-live this service life. The oil is hermetically sealed from the air by a stainless-steel diaphragm assembly and all external parts are of corrosion-resistant material.

OSKF

Oil-Insulated Current Transformers (CT) up to 800 kV

GE Vernova’s OSKF have been designed for a 30 year lifetime and, thanks to the profound technical concepts, many well out-live this service life. The oil is hermetically sealed from the air by a stainless-steel diaphragm assembly and all external parts are of corrosion-resistant material.

Recommended Products & services

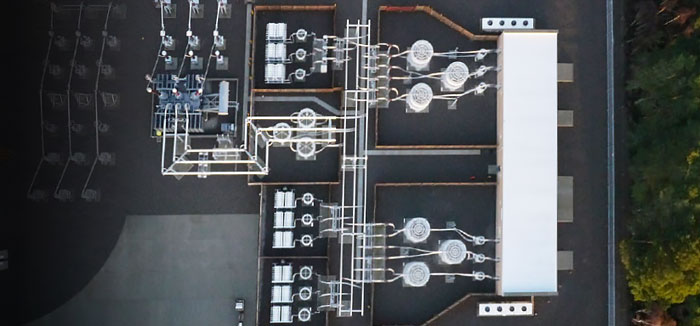

Mobile Substations

A complete range of flexible solutions

Substations play a crucial role in the transmission and distribution of electrical power throughout the grid. So what happens if a substation goes off-line? GE Vernova's mobile substations can bridge the gap during off-line events, helping to keep the grid operational and safe.

Mobile Substations

A complete range of flexible solutions

Substations play a crucial role in the transmission and distribution of electrical power throughout the grid. So what happens if a substation goes off-line? GE Vernova's mobile substations can bridge the gap during off-line events, helping to keep the grid operational and safe.

Key Benefits

GE Vernova's mobile substations are a turnkey solution, adapted to the specific requirements of each customer. Each project is unique and our project management team works closely with our customers to make sure that the huge range of possibilities are focused to the ideal customized solution.

Key benefits of GE Vernova's mobile substations

- No civil works cost

- Reduced maintenance costs

- Maximum utilization and return on investment

- Maximum mobility and flexibility

- Can be rapidly on site and available for service

- Maximum reliability through customized design

- Optimization of space equipment

- Reduced or minimal dismantling cost

Configurations

There are several possible configurations for mobile substations, depending on client requirements and local traffic regulations.

| Type of substation | Max. voltage level | Other characteristics |

|---|---|---|

| GIS | 220 kV | Complete bay |

| Hybrid - AIS | 145 kV | Complete bay, incl. power transformer up to 10 MVA |

| MV cubicles | 52 kV | Several bays, up to 15 cubicles |

| Power transformers | 145 kV | Up to 10 MVA |

| Other ratings available under request and study. | ||

| Type of substation | Max. voltage level | Other characteristics | |

|---|---|---|---|

| GIS | 420 kV | Complete bay | |

| Hybrid - AIS | 170 kV | Complete bay, incl. power transformer up to 60 MVA | |

| MV cubicles | 36 kV | Several bays, up to 19 cubicles | |

| Power transformers | 400 kV | Up to 105 MVA single phase transformer | |

Service & Support

To ensure we provide a solution that is always ready to go, GE Vernova provides a full range of services, from the wheel of the trailer to the top of the bushings. During standby periods or while in use on site, our teams can assess the condition of the equipment, such as the mechanical health of the solicited joints and mechanisms, dielectric health via PD monitoring, quality of the fluids and their sealing for oil or SF6, low-voltage panels integrity, then advise and apply preventive and corrective actions.

To maximize your asset performance and to reduce possible intervention delays due to administrative constraints, GE Vernova offers long-term operations and maintenance agreements, including 24/7 emergency service center assistance.

Recommended Products & services

B105 & T155

Hybrid Gas-Insulated Switchgear

The B105 & T155 H-GIS Hybrid Gas-Insulated Switchgear meet the challenges of networks up to 550 kV in power generation, transmission and heavy industry applications.

The B105 & T155 are compact and accessible, with a bay footprint 40% below the market average. Complete bays are assembled, wired, tested and shipped enabling shorter site works.

B105 & T155

Hybrid Gas-Insulated Switchgear

The B105 & T155 H-GIS Hybrid Gas-Insulated Switchgear meet the challenges of networks up to 550 kV in power generation, transmission and heavy industry applications.

The B105 & T155 are compact and accessible, with a bay footprint 40% below the market average. Complete bays are assembled, wired, tested and shipped enabling shorter site works.

Customer Benefits

Main Characteristics

Environment friendliness

- Lowest gas weight on market

- First-in-class SF₆ sealing system

High availability

- Best experiences and high data reliability

- Current transformers outside SF₆

- Pure-spring circuit breaker drives

- Outstanding accessibility: drives and accessories at easy reach

Short site works

- Complete bays assembled, wired, tested and shipped

Specifications

| General ratings | |||

| Reference electrotechnical standards | IEEE/IEC/GB | IEEE/IEC/GB | IEEE/IEC/GB |

| Voltages | 253 kV | 362/420 kV | 550 kV |

| Withstand voltages | |||

| - Short-duration power-frequency, phase-to-earth / across open switching device | 460/530 kV | 680/815 kV | 710/925 kV |

| - Switching impulse, phase-to-earth / across isolating distance | 1050/900(+345) kVp | 1175/900 (+450) kVp | |

| - Lightning impulse, phase-to-earth / across open switching device | 1050/1200 kVp | 1425/1425(+240) kVp | 1550/1550(+315) kVp |

| Frequency | 50/60 Hz | 50/60 Hz | 50/60 Hz |

| Continuous current | up to 4000 A | up to 5000 A | up to 5000 A |

| Short-time withstand current/Duration of short-circuit | 50-63 kA / 3 s | 63 kA / 3 s | 63 kA / 3 s |

| Ambient temperature range | down to -30 °C / up to +55 °C | down to -30 °C / up to +55 °C | down to -30 °C / up to +55 °C |

| Circuit-breaker ratings | |||

| First-pole-to-clear factor | 1.3 - 1.5 | 1.3 - 1.5 | 1.3 |

| Short-circuit breaking current | 50-63 kA | 63 kA | 63 kA |

| Short-circuit making current | 135-170 kAp | 170 kAp | 170 kAp |

| Operating sequence | O–0.3s–CO–3 min–CO/CO–15s–CO | O-0.3s-CO-3 min-CO/CO-15s-CO | O-0.3s-CO-3 min-CO/CO-15s-CO |

| Drive type | Pure-spring | Pure-spring | pure-spring or hydraulic |

| Breaking time | 3 cycles | 2 cycles | 2 cycles |

| Mechanical endurance | M2 class | M2 class | M2 class |

| Capacitive switching | C2 class | C2 class | C2 class |

Recommended Products & services

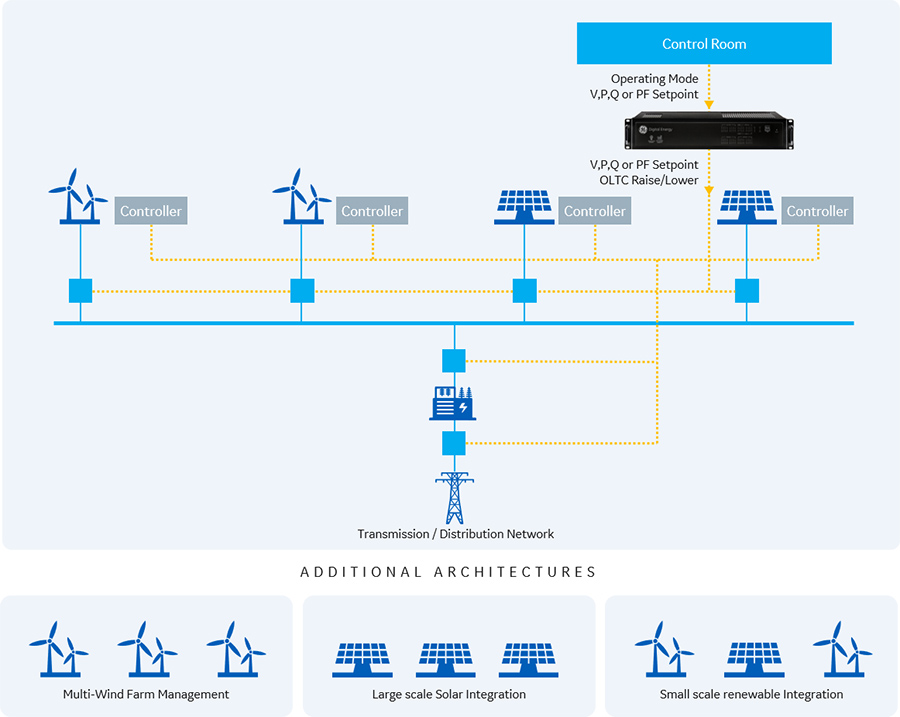

GridNode DER Management Solution

Energy trends of renewable penetration and decentralization of generation assets create new industry challenges. These challenges include integration, coordination, and maximizing return-on-investment (ROI) on distributed energy resources (DERs), while providing network reliability and flexibility.

GE Vernova's GridNode Distributed Energy Resources (DER) Management solution enables utilities and developers to easily integrate renewable energy resources

GridNode DER Management Solution

Energy trends of renewable penetration and decentralization of generation assets create new industry challenges. These challenges include integration, coordination, and maximizing return-on-investment (ROI) on distributed energy resources (DERs), while providing network reliability and flexibility.

GE Vernova's GridNode Distributed Energy Resources (DER) Management solution enables utilities and developers to easily integrate renewable energy resources

What is a Distributed Energy Resource (DER)

"A Distributed Energy Resource (DER) is any resource on the distribution system that produces electricity and is not otherwise included in the formal NERC definition of the Bulk Electric System (BES)". ~ NERC . Distributed Energy Resources are sometimes referred to as Distributed Generation, Distributed Energy, or Decentralized Energy and typically consist of renewable energy sources such as solar, wind, and storage.

Challenges with Integrating Renewables

- Reliability issues associated with connecting DERs onto the grid

- Coordination, Flexibility and Control of DER resources from different vendors for optimal and/or equal market participation

- Maximizing Return on Investment (ROI) through energy market participation

- Cost of Ownership and CAPEX

- Stress on existing network infrastructure

Benefits of GE Vernova’s GridNode: DER Management Solution

- Increase Reliability and Flexibility – Increase functionality and grid support capabilities, monitoring, and control

- Reduction in CAPEX – Life Extension of Assets, Ease of Operation

- Increase Revenue – Ability to provide grid support (Reactive Power)

- Increases Asset Life – Reduced OLTC Operations

GridNode DER Management Solution is a flexible and scale-able platform that incorporates various dispatch modes and control capabilities to easily integrate renewable energy onto the grid. The GridNode platform is vendor agnostic having the capability to integrate GE Vernova and 3rd party devices and assets.

GridNode: DER Management Solution

Dispatch Modes

GridNode: DER Management Solution, has the capability to dispatch commands to the connected DERs in one of the modes below in order to achieve the provided setpoint at the point-of-interconnection (POI).

Voltage

Reactive Power

Active Power

Power Factor

The GridNode: DER Management Solution considers the network limits and parameters and the individual DERs capacities and constraints when dispatching commands to each DER. In addition, the GridNode solution is capable to controlling a tap changer if required to obtain the desired value at the point of interconnection (POI).

Control Capabilities

Equitable Dispatch

- Ability to equitable dispatch the setpoint provided by the operator or DMS in an equitable manor, considering the system limits, across all DER assets.

Ramp-Rate Control

- Ability to control the ramp rate of the intermittent renewables connected to the system.

Feeder Controls

- Ability to integration feeder controls and monitoring into the solution

Volt-Var Control

- Ability to issue raise and lower commands to OLTCs, when the DER capabilities are exhausted

Services

GE Vernova's engineering and consulting services team provides a wide range of capabilities to assist you with integrating renewables.

Our dedicated team of experienced engineers can provide end-to-end solutions or specific activities based on the specific project requirements. From new installations to understanding the best way to upgrade an existing system, GE Vernova’s engineering team has been trusted to analyze, design and implement modern power systems.

Recommended Products & services

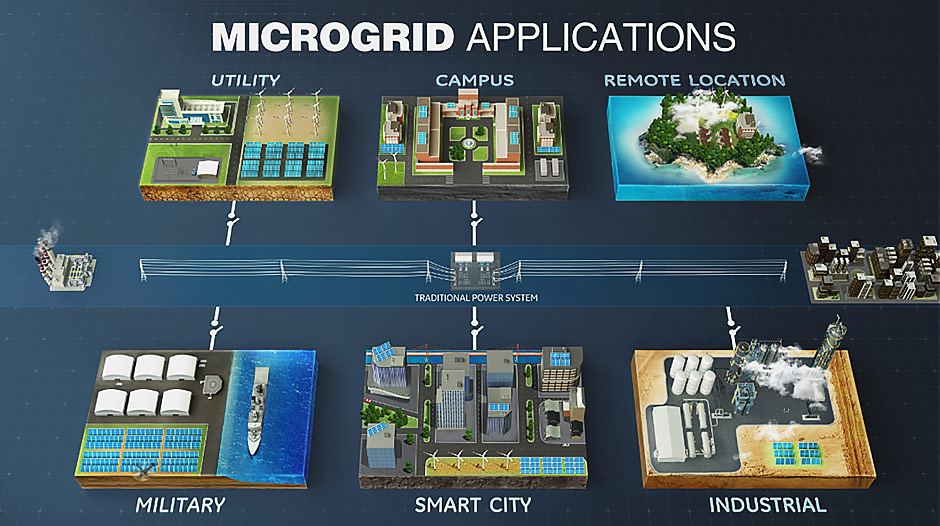

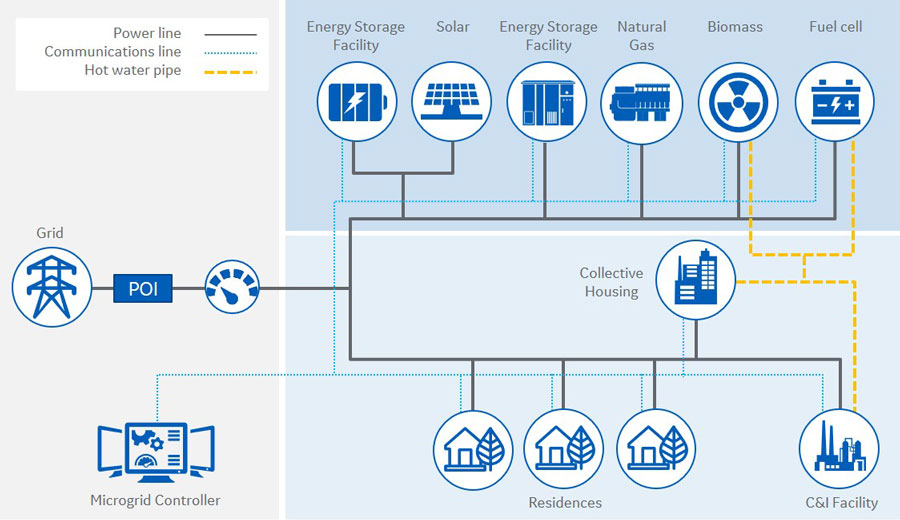

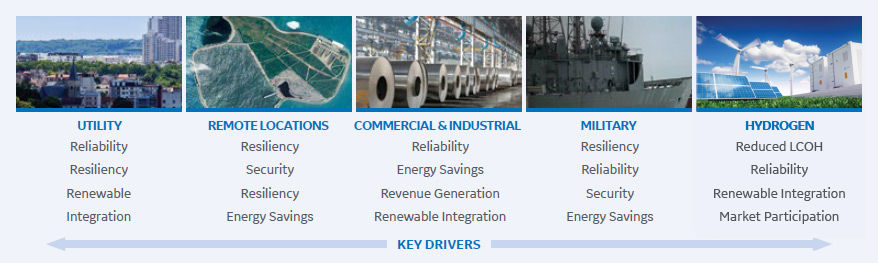

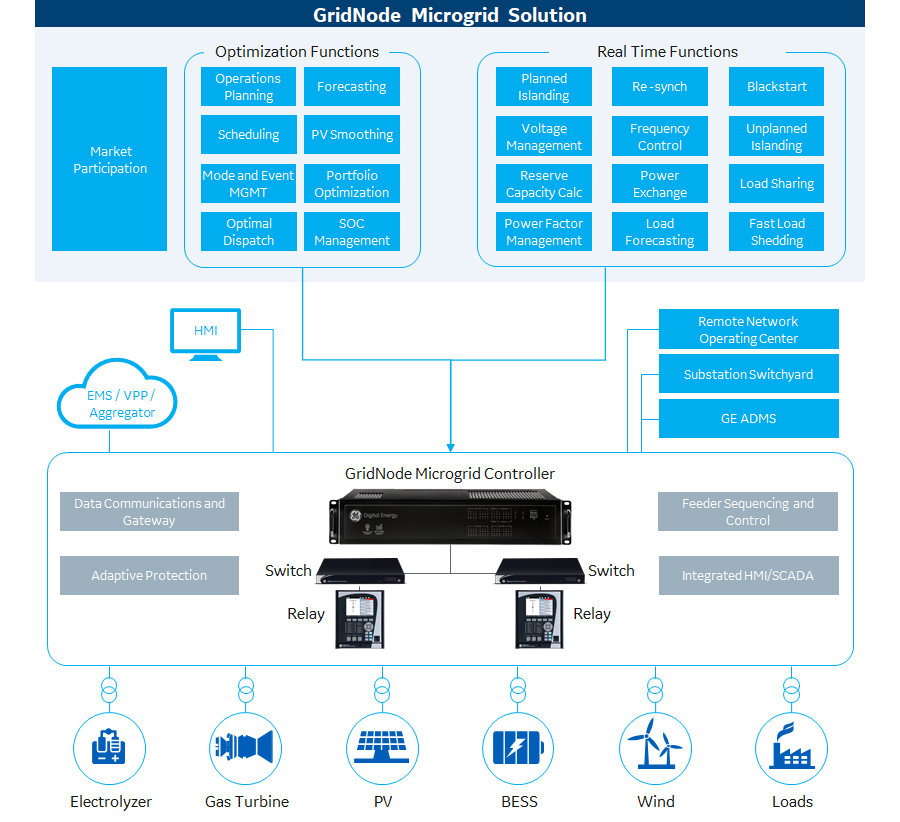

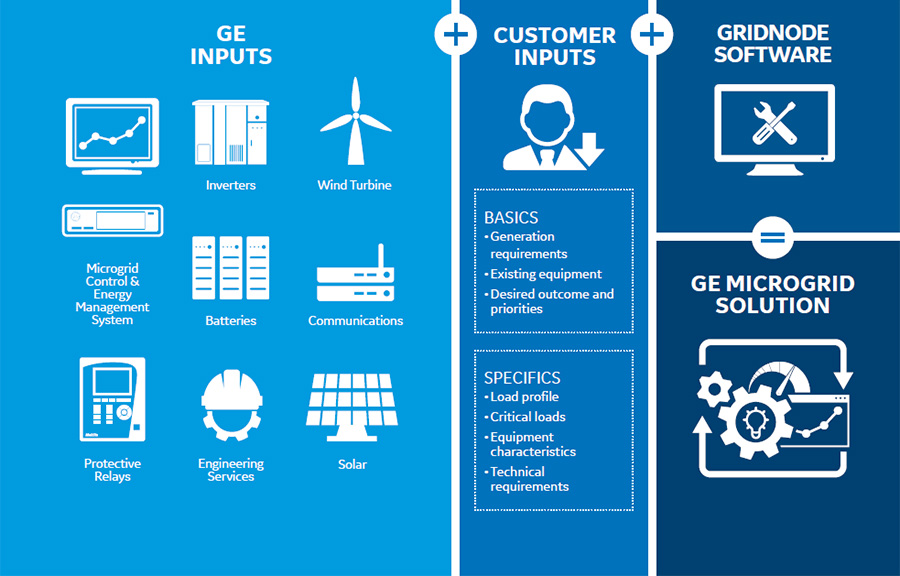

GridNode Microgrid Solutions

Global energy trends of electrification, decarbonization, digitization, and decentralization are changing the current energy landscape. These trends combined with customer’s demand for solutions that provide increasing reliability, resiliency, sustainability, energy independence and energy cost reduction has led to the growing demand for microgrids.

GridNode Microgrid Solutions

Global energy trends of electrification, decarbonization, digitization, and decentralization are changing the current energy landscape. These trends combined with customer’s demand for solutions that provide increasing reliability, resiliency, sustainability, energy independence and energy cost reduction has led to the growing demand for microgrids.

What is a Microgrid

"A microgrid is a group of interconnected loads and distributed energy resources (DERs) with clearly defined electrical boundaries that acts as a single, controllable entity with respect to the grid. A microgrid can connect and disconnect from the grid to enable its operations in both grid-connected or islanded mode" – US DOE Microgrid Exchange Group, 2010

Why a Microgrid

Today’s energy trends of Decarbonization, Digitization, Decentralization, and Electrification are changing the energy landscape. In addition, customer demand for clean, reliable, and economical energy is growing. Microgrids provide a way for customers to achieve various outcomes across different segments.

GridNode Microgrid solution is a flexible and scale-able platform that incorporates various real time control and optimization functions based on the customer’s requirements and desired outcome. The GridNode platform is vendor agnostic, having the capability to integrate GE Vernova and 3rd party devices.

GridNode Microgrid Solution Functions

Control Functions

Customer Benefits Include:

Autonomous Control and Flexibility

Planned And Unplanned Islanding

- Ability to transition between the Grid-connected mode and Islanded mode

Resynchronization

- Ability to seamlessly transition from the Islanded mode to the Grid-connected mode

Power Exchange at POI

- Ability to dispatch microgrid resources in order to manage power flow at the POI

Frequency Control

- Coordinate dispatch of various DERs to control the frequency of the island and control power flow during Grid Connected Mode

Power Factor Management

- Ability to dispatch microgrid resources to manage power factor at a reference point (e.g., POI)

PV Firming

- Ability to provide a firm the PV output on a real time basis

Voltage and Frequency Support

- Ability to dispatch microgrid resources in order to support the Voltage or Frequency of the Grid

Load Sharing

- Ability to control microgrid resources to regulate feeder voltage or the voltage at a reference point on the grid

Reserve Capacity Management

- Managing the reserved capacity of the microgrid to enhance remaining life of the island

Voltage Control

- Coordinate dispatch of various DERs to control the voltage of the island and control power flow during Grid Connected Mode

PV Curtailment

- Ability to curtail PV output to manage the power generation of the microgrid

Load Forcasting

- Ability to generate a day-ahead load forecast for optimal dispatch planning

Optimization Functions

Customer Benefits Include:

Energy savings, renewables enablement, emissions reduction

Optimal Dispatch

- Simplified/easy to use mode based DER optimal dispatch function

- Optimization Modes: Economics, Priority, Max Time of Life and Peak Shaving

- Incorporates load and renewable generation forecast

- Incorporates Grid Pricing

- Manages Reserve Capacity and BESS State of Charge

Ability to consider Power Export and Grid Services

Microgrid Energy Management System (MEMs)

Customer Benefits Include:

Ability to actively manage, schedule, plan, and monitor your optimal dispatch plan

Energy Optimization Platform

- Optimization Modes: Economic Dispatch, Peak Shaving, Minimize Emissions, Minimize Grid, Maximize Time of Life, and Maximize Renewables

- Provides a day-ahead (24hr) schedule, with 15min granularity

- Incorporates load and renewable generation forecasts

- Incorporates Grid Pricing

- Optimizes across DERs and Loads

- Manages Reserve Capacity and Battery SOC (Hard and Soft Limits)

- Provides Event Based Optimization changes

- Ability to compare various optimization scenarios prior to activating

- Ability to consider Power Export and inclusion of grid services

Advanced Functions

Customer Benefits Include:

System Reliability

Seamless Unplanned Islanding (FLS)

- Ability to perform adaptive fast load shedding to facilitate seamless unplanned islanding for reliability-centric microgrids

Market Participation

Customer Benefits Include:

Revenue Generation and Renewables Enablement

Market Participation

- Ability to integrate your system into the energy markets

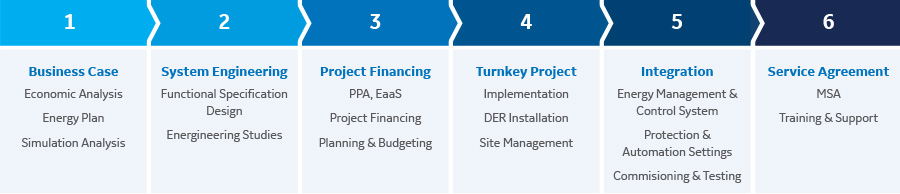

Business Model

As with most projects a microgrid project requires effective planning, analysis, and execution. Projects can range from large scale new installations consisting of engineering procurement, and construction of buildings, new DERs, electrical and mechanical equipment, protection and controls, as well as services to retrofits of existing systems with new microgrid controls. When required, GE Vernova partners with industry leaders to develop and design a system around our customers desired outcome. This approach enables GE Vernova to deliver a full turn-key solution.

GE Vernova works with partners to provide a turn-key solution to our customers

Services

GE Vernova's engineering and consulting services team provides a wide range of capabilities to assist you with implementing your microgrid project.

Our dedicated team of experienced engineers can provide end-to-end solutions or specific activities based on the specific project requirements. From new installations to understanding the best way to upgrade an existing system, GE Vernova’s engineering team has been trusted to analyze, design and implement modern power systems. Our broad range of services include activities such as:

Recommended Products & services

Utility & Industrial Substation Projects

Substation and electrical infrastructure projects for utility and industrial customers face a number of challenges in today's environment. Increasing demand and workload peaks, NERC and FERC regulations, and an aging workforce and infrastructure serve as drivers for outsourcing these complex projects.

GE Vernova serves these needs with a comprehensive range of products and services for substation and electrical grid projects that can be delivered as Engineered Equipment Packages (EEP), Engineer, Procure and Construct EPC) and support services.

Utility & Industrial Substation Projects

Substation and electrical infrastructure projects for utility and industrial customers face a number of challenges in today's environment. Increasing demand and workload peaks, NERC and FERC regulations, and an aging workforce and infrastructure serve as drivers for outsourcing these complex projects.

GE Vernova serves these needs with a comprehensive range of products and services for substation and electrical grid projects that can be delivered as Engineered Equipment Packages (EEP), Engineer, Procure and Construct EPC) and support services.

GE Vernova's Advantage

With more than a century of experience in the transmission and distribution industry, GE Vernova's projects team leverages their expertise to provide customers with a number of key benefits.

Extensive Experience

Deep domain knowledge and proven excellence in complex electrical projects results in increased customer confidence and reduced risk.

- Designed and implemented over 1,700 substation projects

- Lead engineering and project management professionals average more than 20 years industry experience

- Experience with large, complex projects valued over $100M

- Unique capability to execute technically complex upgrade projects

On-Time and On-Budget Delivery

Process rigor with seamless project execution and delivery produce streamlined, on-time and on-budget results.

- 99% on-time completion to in-service date

- Greater than 97% on-budget performance

- 50% fewer change orders than industry average resulting in improved price forecasting and total cost of ownership

Industry Leading Safety and On-Site Management Record

Rigorous, best-in-class quality and process standards provide and promote a safe and secure work environment. This ensures systematic project execution, on-time completion of deliverables and the highest level of on-site safety.

- Nearly 1.5 years of project site work without an OSHA

recordable injury - Comprehensive safety program focused on awareness, training and prevention

Comprehensive Integration Capability

A full line of OEM equipment integrated via state-of-the-art 3D knowledge-based design tools provide optimized system designs.

- Pioneered the use of 3D interactive tools that incorporate GE Vernova design experience into repeatable knowledge-based system to drive efficiency, quality and speed

- Simplified and streamlined commercial offerings eliminate project and logistical complexities of multiple vendor projects

Markets Served

GE Vernova's Projects teams serve a number of different market verticals including:

Utility Transmission Substations

GE Vernova leads the North American industry in successful completion of sophisticated and critical electric transmission projects varying from 69kV to 500kv. Typical project types include:

- Greenfield substations

- Capacity upgrades

- Bay additions

- Transformer and circuit breaker change-outs

- Bus reconfiguration and expansion (BAAH, Ring Bus)

- SCADA and protection and control upgrades

Utility Distribution Substations

GE Vernova offers a wide variety of distribution substation solutions, varying from 12kV to 69kV, that incorporate the latest GE Vernova technologies and a modular design that allows for standardization and scalability to cover small, medium and large distribution substations upgrades. Typical project types include:

- Greenfield substations

- Transformer and circuit breaker change-outs

- SCADA and protection and control upgrades

Industrial Substations

GE Vernova's solution is specifically engineered to provide the highest reliability possible, including redundant service if required. GE Vernova has extensive design and construction experience in building new or upgrading existing industrial substations including:

- Oil & Gas

- LNG/Petrochemical

- Metals & Mining

- Steel/paper/cement

Renewable Substations

(Wind & Solar)

GE Vernova provides Electrical Balance of Plant (EBoP) for wind and solar grid interconnect with a full line of solutions, products and services to support the development, design, installation and operations of renewable generation facilities. GE Vernova has designed and constructed nearly 10% of the wind generation connected to the North American grid.

Multi-year Upgrade Programs

GE Vernova provides multiyear programs to utilities and customers for a range of project types. A program approach is generally used for a group of projects that have a set criteria, common goals or anticipated results. For example, a customer may need to replace specific equipment or upgrade systems at multiple substations over an extended period of time. Typical project types can include:

- Protection and control hardware upgrades

- New or existing communications and SCADA upgrades

- Replacement of specific switchyard equipment, including transformer and circuit breaker change-outs

Specialized Technology Applications

Gas Insulated Switchgear Substations

GE Vernova provides Gas Insulated Switchgear (GIS) Substations ranging from 69kV to 500kV for utilities and industrial customers with a full complement of primary and secondary equipment, services and solutions to build and retrofit electrical infrastructure. GE Vernova's compact and modular design minimizes the installation footprint.

IEC 61850 Process Bus Solution

With the unique Multilin™ HardFiber Brick solution, GE Vernova offers customers an alternative to traditional copper wired substation designs that significantly reduces installation costs. This enabling technology creates a reliable high-speed network with the ability to connect and transmit data from the substation to an Advanced Distribution Management System (ADMS) or Energy Management System (EMS). The Multilin HardFiber Brick solution complies to the IEC 61850 global industry standard

Modular Control Buildings

GE Vernova provides electric utility and industrial customers with Modular Control Buildings intended for use in transmission and distribution substations. The Modular Control Building is manufactured in a controlled environment. The panels are wired and cabled to an intertie box that accepts the field cables from the switchyard equipment. The entire building and panels are pretested at the factory and shipped to site to be set on piers or a slab foundation.

Recommended Products & services

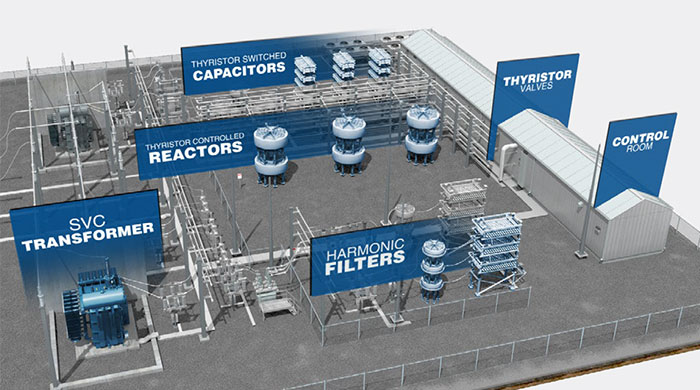

Static Var Compensator Solutions

Increasing Grid Reliability

GE Vernova’s Static Var Compensator (SVC) solutions are a cost-effective and efficient means to provide dynamic voltage support and maintain the reliability and efficiency of power supply. These solutions are highly reliable, easy to integrate into both existing and new infrastructures, and reduce the investment required for building new network extensions.

Static Var Compensator Solutions

Increasing Grid Reliability

GE Vernova’s Static Var Compensator (SVC) solutions are a cost-effective and efficient means to provide dynamic voltage support and maintain the reliability and efficiency of power supply. These solutions are highly reliable, easy to integrate into both existing and new infrastructures, and reduce the investment required for building new network extensions.

GE Vernova Advantage

GE Vernova’s SVC solutions are customized based on the utility’s technical and economic requirements for their network such as fault level and load parameters. GE Vernova provides an extensive services portfolio comprised of feasibility and network studies, project management, engineering capabilities, equipment, installation services and long term maintenance contracts, delivering an integrated and robust system that provides utilities with the following competitive advantages.

Model Based Design Control ensures optimal and accurate performance of the SVC by direct deployment into the system software

- Rapid technical responsiveness to the customer, from planning support and project execution to commissioning

- Intuitive graphical interface provides fast, automatic, and error free code generation from control models, ensuring a greater level of confidence to the customer

- Ease of integration into control system software with power system modeling tools such as PSCAD provides an accurate representation of system performance for planning and transients analysis

- Modular hardware design based on commercial off-the-shelf components which provide extensive scalability to any project rating, while maintaining quick system delivery time and simple life-cycle Management

Classic SVC and GE Vernova’s patented Main Reactor SVC provides more design flexibility to ensure optimized system performance

- Broad range of SVC configurations including: classic, hybrid, Main Reactor, fixed, modular, relocatable, low noise, and reduced footprint designs

- Ground level power to the thyristor valves provide system voltage independence and benefits operation at very low voltages, increasing SVC readiness during severe system events

- Unique Main Reactor configuration improves harmonic performance, reduces operational losses and design footprint, and ensures regulatory compliance at the point of interconnection

Manufacturing excellence and deep domain technical expertise providing full system lifecycle support resulting in simplified and streamlined commercial offerings

- Deep technical expertise gained though more than 50 years’ experience on more than 380 global installations ranging from small industrial to large utility projects, in diverse applications and extreme environmental conditions

- Full range of lifecycle support competencies including network analysis, system design, engineering, procurement, civil works, installation, testing and commissioning and asset management, eliminating project and logistical complexities of multiple vendor projects

- SVC main components are vertically integrated within GE Vernova’s advanced manufacturing facilities, which are certified to ISO 9001, ISO 14001 Environmental Standards and OHSAS 18001

GE Vernova’s Classic SVC Design

-100/+200Mvar classic SVC design

-100/+200Mvar classic SVC design

GE Vernova’s Classic SVC design is customized based on the utilities key requirements for system performance. Every system is tested extensively during factory acceptance testing and site commissioning to ensure guaranteed performance.

Benefits of classic SVC design:

- Allows grid operators to gain accurate control of network reactive power and voltage

- Increases power transfer capability

- Improves steady-state and dynamic stability of the grid with very fast response times

Main components of the system include:

- SVC transformers

- Thyristor Controlled Reactors (TCR)

- Thyristor Switched Capacitors (TSC)

- Harmonic Filters

- Advanced Thyristor Valve (ATV)

- Advanced Digital Control (ADC)

- Protection and Auxiliary systems

- Thyristor valve cooling system

System ratings include:

- Typical utility voltage levels: approx. 69 < kV < 800

- Typical utility overall ratings: approx. 40 < Mvar <1,200

Example of a classic SVC design

-100/+200Mvar Main Reactor design, with smaller footprint

-100/+200Mvar Main Reactor design, with smaller footprint

GE Vernova’s Patented Main Reactor SVC Design

GE Vernova’s patented Main Reactor SVC design is customized based on the utility’s key requirements for system performance. Every system is tested extensively during factory acceptance testing and site commissioning to ensure guaranteed performance.

Traditionally, the SVC medium voltage bus is connected directly to the SVC coupling transformer, but with the main reactor configuration there is a reactor connected between SVC bus and coupling transformer.

The Main Reactor concept efficiently isolates harmonics, even in demanding network conditions. This design requires fewer harmonic filters enabling a compact, optimized SVC layout.

The Main Reactor has many other inherent benefits for improved harmonics, simpler design and cost savings, including:

- Main Reactor blocks harmonics generated by the SVC

- Lower amount of filtering is needed

- Improved harmonic distortion at the Point of Common Coupling

- Less harmonic stress on the SVC coupling transformer

- Lower voltage stress on all components

- Minimized requirement for Thyristor Switched Capacitors (TSC), potentially eliminated

- Thyristor Controlled Reactors (TCR) has smaller coils, lower losses and reduced number of thyristor valve levels

- Only low order filters are needed (reactor blocks high order), wide filtering band can be used

Main components of the system include:

- SVC Transformers

- Thyristor Controlled Reactors (TCR)

- Main Reactor

- Harmonic filters

- Advanced Thyristor Valve (ATV)

- Advanced Digital Control (ADC)

- Protection and Auxiliary systems

- Thyristor valve cooling system

Example of a Main Reactor SVC design

Advanced Digital Control platform for SVC systems

Advanced Digital Control platform for SVC systems

GE Vernova’s Advanced Digital Control for SVC Systems

GE Vernova’s approach to SVC Control System represents the latest in design methodology by utilizing a powerful Model Based Design approach. With this approach the SVC Control System software is built using a core library of complex control algorithms that represents over 50 years of FACTS experience within GE Vernova. Model Based Design utilizes a graphical interface for the design stage and translation of control models with automatic code generation for all testing and verification stages. With this approach, GE Vernova has enhanced the quality, reliability, and maintainability of the Advanced Digital Control system for SVCs.

Model Based Design Advantages

- With Model Based Design, programming and customization of control functions is simplified by the use of a graphical programming interface.

- Testing and verification of the control system at the design stage starts early using real-time control models in closed loop with the SVC power electronics and the power grid.

- Simulation environment uses real-time control models providing the most accurate representation of control performance. The control models can be easily exported to PSCAD™ or similar tools with one-to-one representation for further testing and simulations.

- Automatic code generation allows direct conversion of graphical control models into real-time control software, eliminating the manual “coding stage”, resulting in improved quality and reliability.

- Complete traceability of customer requirements throughout the control model provides easy and efficient way for software modifications and new feature implementation at any stage of the project.

- Model Based Design approach adopted by GE Vernova has already revolutionized the development approach for critical control software in aviation, space and automotive industries, resulting in significant improvement in software quality for critical and life-supporting applications.

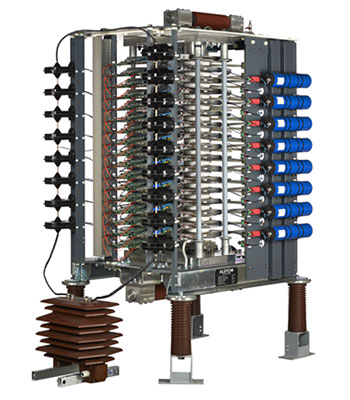

GE Vernova's Advanced Thyristor Valve

GE Vernova's Advanced Thyristor Valve

Thyristor Controlled Reactor and Thyristor Switched Capacitors

Thyristor valves are used for controlling reactive power in Static Var Compensators. Thyristor Controlled Reactor (TCR) valves are used to control the effective fundamental frequency current in the reactors by controlling the conducting ratio through varying the firing angle of the thyristors. Thyristor Switched Capacitors (TSC) bank valves are used for switching capacitor banks on or off according to the reactive power demand on a time scale of several periods or more.

Advanced Thyristor Valve for SVC Systems

The Advanced Thyristor Valve (ATV) is GE Vernova’s latest range of liquid-cooled thyristor valves for Static Var Compensator applications. These thyristor valves have been developed by drawing on GE Vernova’s extensive experience of more than 50 years of applying thyristor based SVCs both for transmission and industrial applications. The ATV provides a very compact, versatile and standardized platform for both TCR and TSC variants.

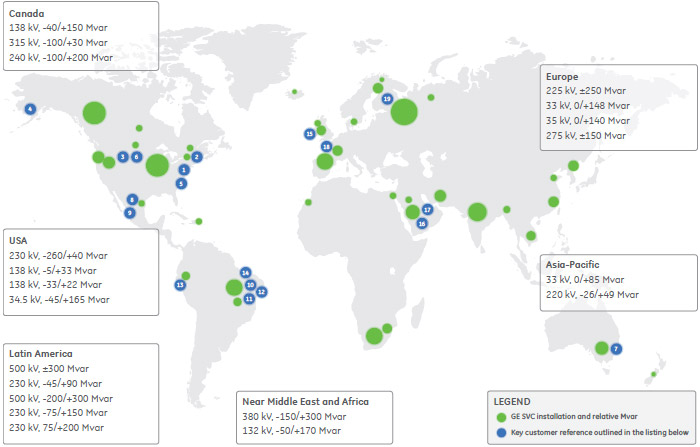

GE Vernova Experience

GE Vernova has designed, delivered and supports over 380 Static Var Compensator Systems globally in a broad range of applications and environments. The below details are a selected representation of recent projects, a complete reference list is available upon request.

Customer References

- Location: West Wharton, NJ, USA

Rating: -260/+40 Mvar, 230 kV - Location: St-Marc-de-Figuery, Canada

Rating: -100/+300 Mvar, 315 kV - Location: Alberta, Canada

Rating: -100/+200 Mvar, 240 kV - Location: Alaska, USA

Rating: Refurbishment of 3 SVCs - (-22 to +22 Mvar) - Wasilla,

AK-(-5 to +33 Mvar) - Fairbanks, AK-(-33 to +22 Mvar) - Healy, AK - Location: Roanoke, VA, USA

Rating: -45/+165 Mvar, 34.5kV (138 kV) - Location: Pasqua, Saskatchewan, Canada

Rating: -40/+150 Mvar in 2x(-20/+75) Mvar, 138 kV - Location: State of Victoria, Australia

Rating: -26/+49 Mvar, 220 kV - Location: Veracruz, Mexico

Rating: -60/+180 to 0/+240 Mvar, 34.5 kV - Location: Mexicali, Mexico

Rating: -75/+200 Mvar, 230 kV - Location: Brazil

Rating: -200 / +300 Mvar, 500 kV - Location: Brazil

Rating: -75 / +150 Mvar, 230 kV - Location: Brazil

Rating: -75 / +150 Mvar, 230 kV - Location: Peru

Rating: ±15 Mvar, 138 kV - Location: Imbirussu, Brazil

Rating: ±100 Mvar, 230 kV - Location: Scotland, UK

1st Installation of GE Vernova’s patented Main Reactor design

Rating: -150 / +150 Mvar, 275 kV - Location: Quway’iyah, Saudi Arabia

Rating: +170 /-50 Mvar SVC - Location: Saudi Arabia

Rating: +300/-150 Mvar SVC and expansion of 110kV GIS at 380kV BSP and two 110kV, 100Mvar bus connected shunt capacitors at 380kV BSP - Location: La Merlatiere and Domloup, France

Patented Main Reactor Design

Rating: ±250 Mvar at 225 kV - Location: Kangasala, Finland

Rating: -200/+240 Mvar, 400 kV - Location: Albany, New Zealand

Rating: ±100 Mvar, 220 kV

Recommended Products & services

Synchronous Condenser

Cost Effective Power Transfer

GE Vernova’s Synchronous Condenser Systems are engineered and designed to provide a highly reliable and efficient solution to address reactive compensation and voltage support requirements, providing transmission operators an optimized solution for cost, performance and operational flexibility.

Synchronous Condenser

Cost Effective Power Transfer

GE Vernova’s Synchronous Condenser Systems are engineered and designed to provide a highly reliable and efficient solution to address reactive compensation and voltage support requirements, providing transmission operators an optimized solution for cost, performance and operational flexibility.

Today’s Challenging Environment

For most utilities ensuring grid reliability, efficiency, and security is a primary concern. As the grid evolves and load profiles change, stresses are being put onto transmission and distribution networks, making the work of grid management much more challenging. Globally, utilities are facing many grid challenges and market condition changes including:

- Changes in generation mix

- Decrease in conventional generation

- Increase in renewable and distributed generation

- Environmental and regulatory policy changes, driving the retirement of traditional coal generating stations

These challenges have an operational impact on the electrical infrastructure, in particular creating an overall deficiency in:

- Reactive compensation support

- Voltage support

- System inertia

- Low short circuit ratios on the network

GE Vernova’s Solution

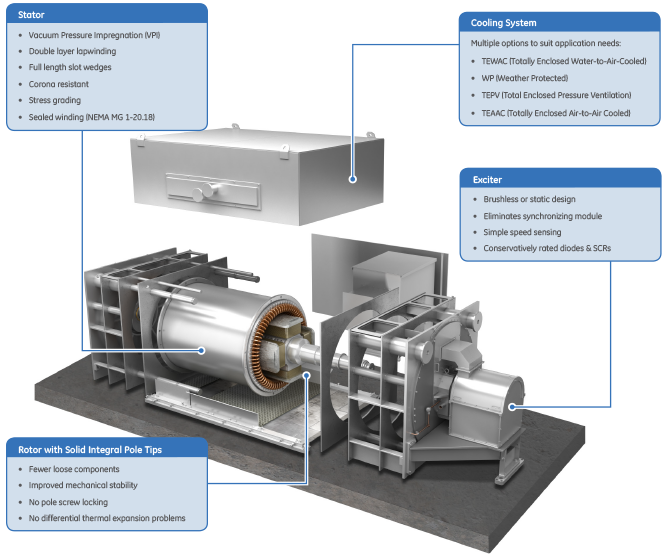

GE Vernova offers transmission utilities a simple and reliable solution to address reactive compensation and voltage support requirements. Our newly re-designed motor based Synchronous Condensers are custom designed to provide transmission operators with a proven, robust and reliable solution.

| GE Vernova Synchronous Condenser Overview | |

|---|---|

| Ratings | Range from 10 to 300 Mvar+ per machine |

| Rotor | Round 2-Pole or Solid Salient Pole |

| Poles | 2, 4 or 6 |

| Excitation | Static or Brushless |

| Starting | Full Voltage, Reduced Voltage, Reactor start, Pony Motor |

| Cooling | TEWAC, TEAAC, WP, TEPV |

The GE Vernova Advantage

GE Vernova’s Synchronous Condenser Systems are engineered and designed to provide a highly reliable and efficient solution, providing an optimized solution for cost, performance and operational flexibility.

Modular design resulting in operational flexibility and decreased down time

GE Vernova has combined multiple synchronous condenser machines into systems that allow for reduced overall footprint, customize Mvar ratings and maintenance flexibility for utilities to reduce operational downtime.

Robust design with extended life resulting in minimal maintenance

GE Vernova synchronous condensers have superior construction, resulting in high efficiency, reliability, and provide easy access for routine maintenance and low vibration for a long life.

Customized design and use of innovate technology resulting in increased reliability and reduced risk of failure

Unique forged integral pole tip design well suited to high load inertia applications. Low mechanical stress is achieved through:

- Fewer loose components

- Improved mechanical stability

- Reduced hot spots during starting

- No pole screw locking concerns

- No differential thermal expansion problems

- Proven experience including the world’s largest 1,800rpm motor

Extensive experience resulting in seamless integration into the utility transmission grid

GE Vernova leads the industry with more than 100 years of experience and the proven synchronous condenser design has been applied in over 200 applications.

Key Benefits of GE Vernova’s Synchronous Condensers

Short-term Overload Capability

The GE Vernova Synchronous Condenser has a large current overload capability. which can provide beneficial system support during emergencies or short term contingencies. As can be seen below, a GE Vernova Synchronous Condenser can provide more than two times its rating for up to 10 seconds. The machine’s significant overload capability can be accounted for in choosing the size of the machine required.

Low Voltage Ride Through

The GE Vernova Synchronous Condenser system has the ability to remain connected and to provide the necessary system benefits even under extreme low voltage contingencies. Mechanical inertia combined with state of the art excitation provides smooth reliable support that is naturally compatible with generation. Power electronic-based solutions do not have mechanical inertia and therefore cannot deliver comparable ride-through performance.

Provides System Inertia

Inertia is an inherent feature of a Synchronous Condenser, since it is a rotating machine. The benefit of this inertia is improved frequency regulation where more renewable generation is being added or where existing generation is being retired.

Response Time

GE Vernova Synchronous Condensers are fast enough to meet dynamic response requirements by using modern excitation and control systems. GE Vernova has integrated today’s advancements in control technologies into a proven machine design to make that solution better than ever.

Short Circuit Contribution

Synchronous Condensers provide real short circuit strength to the grid. Increased short circuit improves system stability with weak interconnections, facilitates system protection and can improve the operation of modern power electronics installations.

Minimal Harmonic Generation

The Synchronous Condenser is not a source of harmonics and can even absorb harmonic currents. The lack of harmonics help make the synchronous condenser friendly to the surrounding grid and other devices. This provides for ease of integration into existing networks.

Minimal Network Interactions

The GE Vernova Synchronous Condenser mitigates system control interaction concern by utilizing traditional and robust electrical components combined with state of the art control architecture that does not cause undesirable interactions with your existing FACTS devices.

Installation & Maintenance Benefits

Fast Project Cycle Time

The system only requires integration to commonly available power delivery components resulting in accelerated project cycle times. The design, manufacture, installation and commissioning of a Synchronous Condenser system can be completed within 16 months. GE Vernova’s experienced Power Projects team has 99% record of on-time project completion and greater than 98% on-budget execution.

Proven Design and Increased Reliability

The GE Vernova Synchronous Condenser is designed to provide trouble-free, reliable service and is a proven solution with more than 200 applications over nearly a century. Advancements in materials and manufacturing techniques, combined with modern control technologies, have greatly improved the reliability and functionality of this robust, time-tested solution. Operators can now utilize the simplicity of electro-mechanical system combined with the benefits of a state of the art excitation and control system in order to meet their grid support needs.

Minimal Maintenance

The GE Vernova Synchronous Condensers proven design requires minimum maintenance resulting in minimal operating costs and reduced total cost of ownership.

Core Components

GE Vernova’s Synchronous Condenser system consists of components commonly used in electric utilities and industrial facilities, with proven robustness and reliability.

Integrated Intelligent Controls

Control Systems & Protection Relays

- Proven controls architecture

- Multilin multi-function digital protection relays

- Secure communications infrastructure

- Human Machine Interface (HMI) operator friendly

- Digital solid state controls

Power Delivery Equipment

- Generator Step Up (GSU) transformer

- HV/MV circuit breakers & switches

- Ancillary systems (lube oil skid)

- Starting reactors

- Instrument transformers (CT/VT)

Typical Applications

HVDC

- Provides Short Circuit Strength

- Dynamic reactive power support (voltage regulation)

- Reduces local harmonic distortion (filter)

Wind/Solar

- Improves or increases short circuit ratio (SCR)

- Dynamic voltage support

- Can improve and extend wind plant capacity ratings

- Provides inertia to improve frequency regulation

Synch Condenser Upgrades

- Higher reliability and efficiency

- Lower total cost of ownership

- Modern controls and excitation – improved response time

Grid Code Compliance

- Enhanced ROCOF (Rate of Change of Frequency)

- Improved LVRT (Low Voltage Ride Through)

Grid Support

- Local voltage support during contingencies and faults

- Provides short term overload capability

- Improves weak AC grid performance

- EHV cables

- Excessive shunt compensation

- Weak AC Grid

Regulatory/Environmental

- Condenser can replace the dynamic voltage regulation and inertia from retired units

- Allows utility to maintain system performance and grid stability

- EPA Coal Requirements

- Once thru cooling requirements

- Generation Retirements

Customer Case Studies

Customer Name

Vermont Electric Company (VELCO)

Location

Granite Substation, Vermont, USA

Application / Challenge:

As part of the Northwest Vermont Reliability Project a number of upgrades were investigated to provide for the reactive power needs at the Granite substation. Simulations indicated that the power system is very near a point of voltage instability. In the case of an outage of the Vermont Yankee – Coolidge 345kV line, a continuous reactive power control device is critical to prevent voltage collapse.

Solution:

- Qty (4) +25/-12.5 Mvar sync condensers

- Qty (4) 25 Mvar shunt banks (MSC)

- Qty (2) Phase shifting transformers

- Integrated control system

Reasons cited for the synchronous condenser over static devices include low voltage ride through capability and the high short time overload characteristics. The overload capability of the condensers provides sufficient time for the mechanically switched 115kV shunt capacitors to be placed into service.

Customer Name

Korea Electric Power Company (KEPCO)

Location

Jeju Converter Station Jeju Island, Korea

Application / Challenge:

The function of a synchronous condenser system in a weak AC grid, and especially one that connects via an HVDC converter terminal, is to improve short circuit strength, provide inertia, and improve reliability.

Solution:

GE Vernova supplied two +50/-25 Mvar synchronous condensers to KEPCO that allow the Chejuu-Haenam HVDC link to continue to cost effectively and efficiently provide power to the island.

With successful installation of the synchronous condensers, KEPCO will be able to retire their existing, converted gas turbine synchronous condensers and transport more power on the existing grid network.

Recommended Products & services

Series Compensation Systems

Cost Effective Power Transfer

GE Vernova’s Series Compensation System allows utilities to cost effectively increase power transfer capabilities of their existing infrastructure and new transmission lines.

Series compensation systems are installed in series with the High Voltage transmission line, and consist of an integrated, custom-designed system with many power capacitors arranged in series and parallel. The most critical equipment is the parallel protective system that prevents damage to the capacitors during power system faults.

Series Compensation Systems

Cost Effective Power Transfer

GE Vernova’s Series Compensation System allows utilities to cost effectively increase power transfer capabilities of their existing infrastructure and new transmission lines.

Series compensation systems are installed in series with the High Voltage transmission line, and consist of an integrated, custom-designed system with many power capacitors arranged in series and parallel. The most critical equipment is the parallel protective system that prevents damage to the capacitors during power system faults.

Overview

Today’s transmission system is becoming increasingly complex and is expected to carry bulk power in ways it was never designed for. The expectation is that transmission requirements will only increase, as power generation sources continue to evolve. GE Vernova’s Series Compensation System allows utilities to cost effectively increase the power transfer capabilities of their existing infrastructure and new transmission lines, leveraging GE Vernova’s capabilities as outlined below.

Extensive Global and Unmatched Technical Experience

A worldwide leader in executing and delivering series compensation projects, in a broad range of utility environments resulting in reduced implementation risk.

- More than a century of experience designing transmission networks, including the first series compensation project in 1928

- Leading the industry by delivering over 30,000 Mvars of series compensation systems in the last three years

- Globally recognized as the foremost technical experts for power system projects since 1928

Industry Leading Patented Technology

Providing superior systems enabled by GE Vernova’s innovate products resulting in project cost savings and increased quality and reliability.

- Fastest Triggered Air Gap (TAG) available in the industry

- Newly patented TAG and Platform Damping Technologies

- Pioneered the use of SSR filter technology in a series capacitor system

Best-in-class Quality and Process Standards

Industry leading and well-established set of project management processes and procedures, certified to ISO® 9001 standards, resulting in on-time and on-budget execution.

- 99% record of on-time project completion

- Greater than 98% on-budget execution

- Over 3.6 million hours of project execution without an OSHA® recordable incident

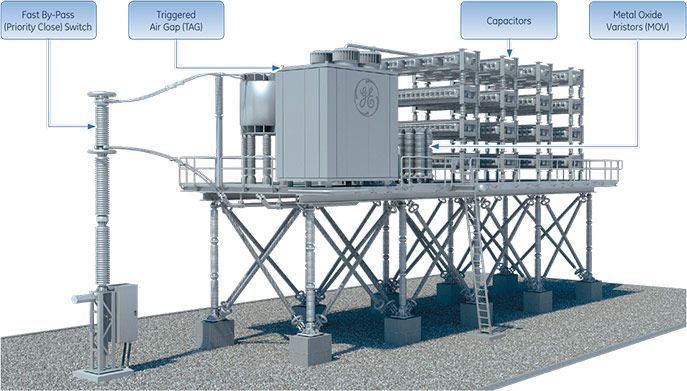

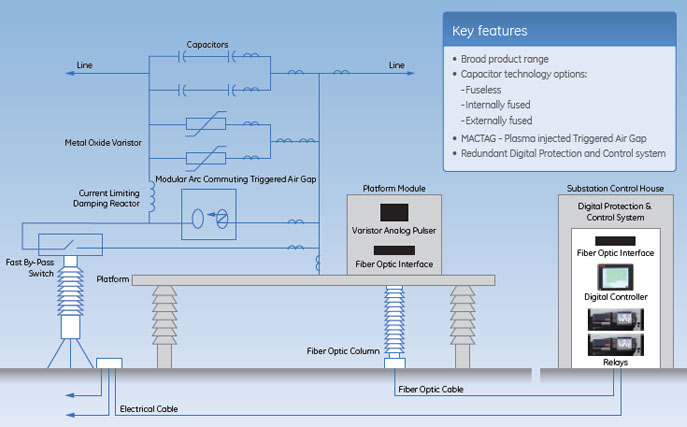

Components of a Series Capacitor Bank

Series Compensation System Components

GE Vernova’s Series Compensation System is comprised with industry leading and patented technology, helping customers achieve high reliability and lowest possible losses on their transmission lines. The major components of the Series Compensation System include Capacitors, Metal Oxide Varistors, Triggered Air Gap, and Fast By-Pass Switches.

Capacitors

The capacitors are placed in series on a transmission circuit intended to reduce the overall line impedance and offers improved load division on parallel circuits, system transient and steady state system stability and allows for increased power transfer capability.

Modular Arc Commutating Triggered Air Gap (MACTAG)

A MACTAG is often used as an intermediate bypass device and is faster than the bypass switch, but not instantaneous like the Metal Oxide Varistor (MOV). GE Vernova’s patented design uses plasma injection to establish an arc which bypasses the capacitors and MOV until the bypass switch can close. GE Vernova’s MACTAG is the fastest in the industry (< 0.3 ms) as it does not rely on ground-based controls to initiate a bypass. A MACTAG lowers MOV cost by reducing the required MOV energy absorption.

Metal Oxide Varistor (MOV)

MOV are the primary device that protects the capacitors from overvoltage by diverting fault current. The MOV are semiconductors that conduct above a specific voltage, known as the Protective Level Voltage. The MOV limits the voltage across the capacitor bank to a safe value for the capacitors handling very high current for short periods of time and protect the capacitors until another bypass path is established.

Fast By-Pass (Priority Close) Switch

The Fast By-Pass Switch closes rapidly to limit both MOV and TAG energy, removing the series capacitors from service. This switch is also used for normal switching to insert the series capacitors or bypass them.

Series Capacitor Bank – One Line Diagram

Capacitor Options

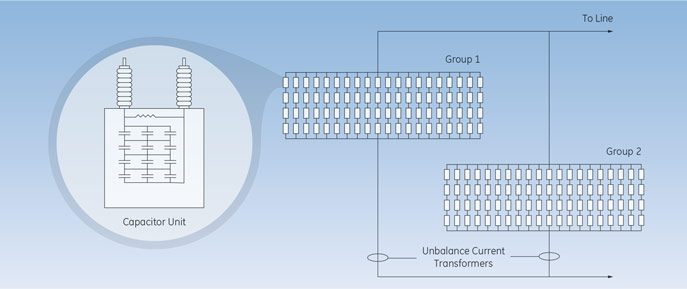

GE Vernova’s Series Compensation offerings include three capacitor options: fuseless, internally fused or externally fused. GE Vernova works with customers to evaluate their requirements and determine the best technical solution to meet customer needs to ensure, reliable and cost effective system.

Fuseless Design

- Lowest losses, typically < 0.12 watts/kvar

- High reliability: A lower internal element voltage stress rise for the same number of internal failures in comparison to an internally fused option

- A higher unbalanced current for the same internal element voltage stress

- Fault tolerance with continued operation even with failed rolls

- GE Vernova recommended option

Internally Fused Design

- Losses typically > 0.15 watts/kvar

- One fuse per internal roll. Each roll is protected by an internal fuse element

- The fuse allows a roll to fail as an open circuit

- There are multiple rolls in parallel. This places a very small incremental stress on adjacent rolls when a fuse operates. This helps prevent a cascading failure within an individual can

Externally Fused Design

- One fuse per capacitor unit. Fewer connections mean fewer points of failure

- Facilitates easy identification of a failed unit as the blown fuse is obvious

- Once the standard, now limited specialty applications

GE Vernova's Fuseless Design

GE Vernova recommends the fuseless option, which has been the dominant technology since the late 1990’s and is proven with a long term field failure rate of less than 0.03% per year. The film foil capacitor is a proven GE Vernova design that has been in use since the 1970s. The fuseless design produces the highest unbalance current (easy to detect a failed roll) with the lowest voltage stress on the remaining units (lower chance for a cascading failure). The diagram below depicts the two capacitor groups.

Project Management Approach

The GE Vernova project team represents unsurpassed worldwide power system engineering capabilities, comprehensive system design expertise, and unequaled project management experience. Our strength in each of these areas enables us to deliver a highly reliable solution that will fully meet your power system requirements. With each reactive compensation project GE Vernova undertakes, this team is committed to delivering 100% satisfaction.

Professional Services Process and Key Activities

Global Experience and Application Examples

GE Vernova’s Series Compensation Systems brings together an extensive portfolio of products, services and engineering excellence to deliver the next generation systems for customers based on specific requirements to address both technical and business objectives as well as support several applications. GE Vernova provides highly reliable and efficient designs that have low overall maintenance and cost of ownership. Below are just a few of GE Vernova’s selection of customer applications.

Cross Texas Transmission

Three Phase Bank Rating: 2 x 716 Mvar

Substations: Turkey, Texas – Cross Station 1 & 2

Customer Challenge

Maintain voltage stability and efficient operations of the Texas Transmission System under minimum and maximum export of wind power.

Customer Application

50% compensation on 2 transmission lines from Tule Canyon to Tesla required series compensation to reduce the inductive line impedance compiled due to long line length.

Customer Benefit

Ability to maximize amount of wind power to be transferred across the new 345 kV transmission lines.

Electricity of Vietnam

18 banks from 2012 - 2016

6,588 total Mvar in operation and awarded

Customer Challenge

Improve capacity of the 500 kV Vietnam transmission system with a compressed amount of time of less than 12 months to install systems.

Customer Application

Increase in the power transfer capability of existing transmission lines.

Customer Benefit

Increased reliability of existing transmission systems, improved voltage support and amount of power transfer capability and timely delivery of equipment meeting compact schedule requirements.

Electric Transmission Texas, LLC

Joint venture a joint venture between subsidiaries of American Electric Power and Berkshire Hathaway Energy

Edison, Gauss, Kirschoff, and Orsted Substations.

Customer Challenge

Need to provide reliable and efficient power across the new 345-kV transmission lines required to maximize the transfer of renewable generation. Must not negatively interact with the existing generation or system – Sub Synchronous Resonance concerns.

Customer Application

Eight series compensation banks located at four different sites to enable the maximum amount of power transfer capability on new 345-kV transmission lines in the CREZ regions throughout Texas.

Customer Benefit

Reliable and efficient means to transfer power from renewable generation on the new 345-kV transmission lines in the CREZ areas.

BPA (Bonneville Power Administration)

Three Phase Bank Rating: 2 X 675 Mvar

Substations: Bakeoven 1 & 2

Customer Challenge

Need to provide reliable and efficient power across the 500 kV California-Oregon Intertie . Required to increase the overall power transfer capability across the tie to facilitate the increase in capacity requirements from renewable generation projects being added to the regional system.

Customer Application

To enable the maximum amount of power transfer capability on the California-Oregon 500 kV transmission intertie.

Customer Benefit

Reliable and efficient means to transfer power from renewable generation on the new 500 kV transmission California-Oregon Intertie. GE Vernova supported a staged fault test performed by BPA, which demonstrated the capability of the GE Vernova Series Capacitor banks to withstand a close-in fault with no damage.

Modular Arc Commutating Triggered Air Gap (MACTAG)

GE Vernova’s family of Modular Arc Commutating Triggered Air Gap (MACTAG) solutions represent the industries leading technology for fast protective devices. The patented technology provides fast, reliable bypass protection, which can reduce the amount of Metal Oxide Varistors (MOV) required on a series capacitor bank resulting in project cost savings.

Customers can realize the following potential advantages with GE Vernova’s MACTAG solutions including:

- Enhanced Fault Durability and Voltage Withstand Performance

- Higher Protective Level Ratings with Fast Recovery Time Validated by Independent 3rd Party

- 50% Smaller Footprint with Reduced Installation Time

GE Vernova’s MACTAG is available in two models: MACTAG 240 and MACTAG 360. The MACTAG models are the fastest TAG’s in the industry and suitable for fast recovery applications. For applications where fast recovery time is not required, a Pilot Gap only option is available. The models include:

Modular Arc Commutating Triggered Air Gap

- MACTAG 240, maximum protective level of 240-250kV*

- MACTAG 360, maximum protective level of 360-400kV*

( * Depends on the application )

MACTAG 360

MACTAG 360

MACTAG 240

MACTAG 240

Pilot Gap (Suitable where fast recovery is not required)

- PG 240, maximum protective level of 240-250kV*

- PG 360, maximum protective level of 360-400kV*

PG 240

PG 240

PG 360

PG 360