Capacitors for High Current, Power Semiconductor and DC Applications

Capacitors for power electronics require special high performance designs for varied applications. This catalog describes capacitors for a number of demanding applications where high currents and/ or high voltages are common. Given the special nature of these types of applications, care must be taken to ensure that the capacitors are correctly applied. Information is included to help with the more common application conditions. An application data sheet is also provided to enlist the help of GE Vernova’s Application Engineers.

Capacitors for High Current, Power Semiconductor and DC Applications

Capacitors for power electronics require special high performance designs for varied applications. This catalog describes capacitors for a number of demanding applications where high currents and/ or high voltages are common. Given the special nature of these types of applications, care must be taken to ensure that the capacitors are correctly applied. Information is included to help with the more common application conditions. An application data sheet is also provided to enlist the help of GE Vernova’s Application Engineers.

Recommended Products & services

Active Filters

GE Vernova’s portfolio of active filters include the GEMActive™ and Maxsine™ filters. They effectively cancel harmonics by dynamically injecting out of phase harmonic current. Installation of the active filters will allow for compliance with IEEE 519 – 1992 recommended harmonic limits. Reduced harmonic levels results in improved electrical network reliability and reduced operating costs. Nuisance tripping of protective devices and nuisance clearing of fuses due to harmonic heating effects is greatly reduced.

Active Filters

GE Vernova’s portfolio of active filters include the GEMActive™ and Maxsine™ filters. They effectively cancel harmonics by dynamically injecting out of phase harmonic current. Installation of the active filters will allow for compliance with IEEE 519 – 1992 recommended harmonic limits. Reduced harmonic levels results in improved electrical network reliability and reduced operating costs. Nuisance tripping of protective devices and nuisance clearing of fuses due to harmonic heating effects is greatly reduced.

Recommended Products & services

Fast Switching Capacitor Banks (Flicker Banks)

GE Vernova offers quick responding, transient free reactive compensation and harmonic filtering systems. Transient free group switching using electronic switching elements provides fast reacting harmonic filtration; built in three phase network analyzer measures network parameters including harmonics; Real time switching (less than 1 cycle) is also available as an option; Single-phase control available as an option for severely unbalanced loads or special applications.

Key features & benefits:

Fast Switching Capacitor Banks (Flicker Banks)

GE Vernova offers quick responding, transient free reactive compensation and harmonic filtering systems. Transient free group switching using electronic switching elements provides fast reacting harmonic filtration; built in three phase network analyzer measures network parameters including harmonics; Real time switching (less than 1 cycle) is also available as an option; Single-phase control available as an option for severely unbalanced loads or special applications.

Key features & benefits:

Recommended Products & services

Low Voltage Capacitor Banks

GE Vernova provides a wide range of automatic and fixed power factor equipment available with and without filters. GE Vernova’s line of GEM™ capacitors are manufactured with high-grade metallized polypropylene film. Low loss polypropylene film with metallized electrode provides smaller, lighter units. Dielectric self-healing characteristics, plus internal Pressure Sensitive Interrupters, result in a double assurance of safety. Multiple cell construction allows for complete flexibility in capacitor selection.

Instant “Self-Healing” Feature

Low Voltage Capacitor Banks

GE Vernova provides a wide range of automatic and fixed power factor equipment available with and without filters. GE Vernova’s line of GEM™ capacitors are manufactured with high-grade metallized polypropylene film. Low loss polypropylene film with metallized electrode provides smaller, lighter units. Dielectric self-healing characteristics, plus internal Pressure Sensitive Interrupters, result in a double assurance of safety. Multiple cell construction allows for complete flexibility in capacitor selection.

Instant “Self-Healing” Feature

Recommended Products & services

Low Voltage Capacitors

GE Vernova’s low voltage capacitor units help customers improve performance through energy savings and better power quality. With our products and solutions, customers save money and reduce the environmental impact of their operations. GE Vernova’s low voltage capacitors are available in a wide range of designs, including internally fused, externally fused and fuseless.

Low Voltage Capacitors

GE Vernova’s low voltage capacitor units help customers improve performance through energy savings and better power quality. With our products and solutions, customers save money and reduce the environmental impact of their operations. GE Vernova’s low voltage capacitors are available in a wide range of designs, including internally fused, externally fused and fuseless.

Recommended Products & services

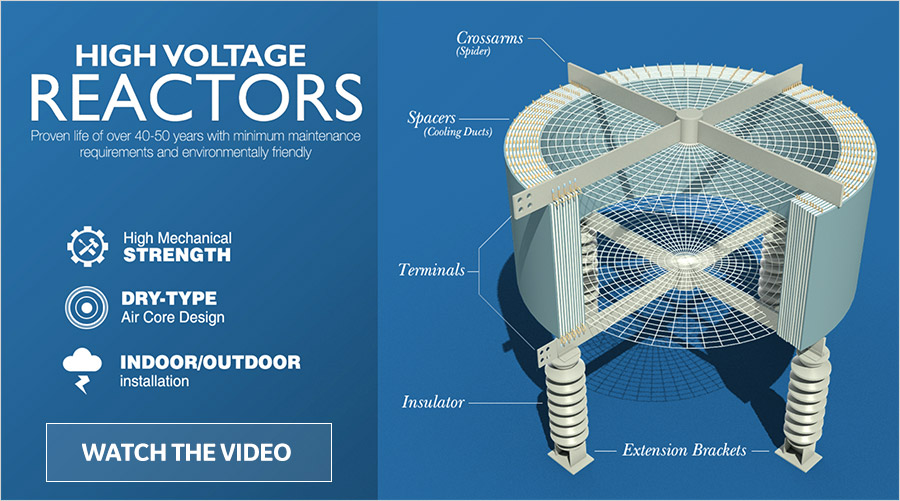

Reactors

Long life with maintenance-free operation and environmentally friendly design

For more than 50 years, GE Vernova has supplied a broad range of reactors to markets around the world. With proven industry expertise, stringent quality controls, first class materials and full international compliance, GE Vernova’s reactors are designed to meet a wide variety of customer needs.

Reactors

Long life with maintenance-free operation and environmentally friendly design

For more than 50 years, GE Vernova has supplied a broad range of reactors to markets around the world. With proven industry expertise, stringent quality controls, first class materials and full international compliance, GE Vernova’s reactors are designed to meet a wide variety of customer needs.

Air-core Reactors

GE Vernova’s air-core reactors (ACR) provide a linear response of impedance versus current which is essential for numerous applications. GE Vernova’s reactors consist of aluminum or copper conductors, which are insulated with first class insulation materials. In encapsulated design, the conductors are mechanically immobilized and encapsulated by epoxy impregnated fiberglass, which assure high hygroscopic characteristic and long service life.

Why GE Vernova’s air-core reactors?

- Complete range of products and solutions in power compensation

- Long term expertise and know-how in power compensation projects

- Full line supplier with synergies between business and product lines

- Proven quality and performance of the products

- Worldwide presence with customer intimacy and proximity

- State-of-the-art in manufacturing process and machinery

Solution portfolio

Our portfolio of air-core reactors includes cost-effective solutions for power generation, transmission and distribution utilities, and industry:

- Shunt reactors

- Current-limiting reactors

- Neutral-earthing reactors

- Harmonic filter reactors

- Damping reactors

- Smoothing reactors

- Arc-furnace series reactors

- Power flow control reactors

- Motor starting reactors

- Special applications, such as test lab reactors

Series Application

Challenge

Integration of new power plants, transmission lines, power transformers and capacitor banks typically increases the normal, transient and short-circuit currents of the transmission and distribution networks. These new current levels exceed the current carrying capabilities of existing equipment.

Solution

GE Vernova’s series reactors provide a cost-effective solution to limit and/or reduce the excessive current levels under normal, transient and short time conditions, assuring quality, reliability and continuity of the power supply.

Shunt Application

Challenge

Transmission and distribution systems operating at low loading levels cause voltage increases in busbars and lines, resulting in insulation failures of the equipment on the grid and overall system instability.

Solution

GE Vernova’s shunt reactors provide system voltage control, operational flexibility, stability and reliability assuring long equipment life and continuity of power supply.

Iron-core Reactors

HV iron-core reactors are connected in series with the capacitor units to form a series resonant circuit with very low impedance. GE Vernova’s line of iron-core reactors are ideal for a variety of applications including capacitor banks formed by several steps, several capacitor banks connected in the same busbar, and capacitor bank installations with risk of resonance or with presence of harmonics.

Key benefits

- Reactive power compensation (power factor correction) in networks with harmonics

- Reduction of inrush currents that flow from step to step of the capacitor banks when switched

- Avoiding the risk of resonance as the LC circuit is having a resonance frequency below the first existing harmonic

- Decrease the level of harmonic distortion, as the circuit is also having a certain tuning frequency at which the branch will offer low impedance path for harmonic currents

Applications for renewable generation, wind and solar farms:

- Shunt reactors (up to 500kV)

- Short-circuit current-limiting reactors (up to 800kV)

- Tuning reactors for harmonic filters and MSCDN

- Damping reactors for shunt capacitor banks

Applications for FACTS, HVDC LCC and VSC, and transmission and distribution substations:

- Thyristor-controlled and thyristor-switched reactors for SVC

- Phase-reactors for STATCOM

- Tuning/blocking reactors for AC/DC, harmonic filters and MSCDN

- Damping reactors for TSC and shunt banks

- Smoothing and valve reactors for HVDC

- Shunt reactors (up to 500kV)

- Short-circuit current-limiting reactors (up to 800kV)

- Power-flow control reactors

- Neutral grounding reactors

Applications for buildings and cities, oil and gas, and industry and infrastructure:

- Shunt reactors (up to 500kV)

- Short-circuit current-limiting reactors (up to 800kV)

- Tuning reactors for harmonic filters and MSCDN

- Damping reactors for shunt capacitor banks

- Arc-furnace reactors

- Motor-starting reactors

- Laboratory reactors (special applications)

Manufacturing Excellence

GE Vernova manufacturing plants are highly automated digital factories that use the GE Vernova Predix platform for machine learning and modeling.

Itajubá, Brazil

Our Itajubá factory supplies a broad range of engineered equipment for all segments and commercial regions, by means of state-of-the-art machinery and design criteria, first class raw material, strict production and quality controls, and very experienced staff.

Products manufactured in Itajubá, Brazil:

- Air-core dry-type reactors

- High voltage capacitor units and banks

- High voltage harmonic filters

- AIS products (instrument transformers, circuit breakers, disconnectors and line traps)

References

For more than 50 years, GE Vernova has provided global support and advanced technologies to +1,000 customers in 80 countries, offering a broad range of reactors for many market segments. GE Vernova is an industry leader in design and manufacturing process with compliance in international technical and certification standards. Below are a select representation of our projects, a complete reference list is available upon request.

1. Canada (2016)

HVDC Smoothing Reactors

AC/DC Filter Reactors

2. USA (1995-2018)

FACTS – SVC & FSC

Shunt Reactors

Current Limiting Reactors

Neutral Grounding Reactors

Damping & Filter Reactors

3. Mexico (2000-201)

FACTS – SVC & FSC

Current Limiting Reactors

Damping & Filter Reactors

4. Brazil (2012)

Rio Madeira HVDC

5. Peru & Colombia (2012-2018)

Current Limiting Reactors

Neutral Grounding Reactors

Damping & Filter Reactors

6. Chile (2010-2017)

FACTS – SVC & FSC

Current Limiting Reactors

Neutral Grounding Reactors

Damping & Filter Reactors

7. Uruguay (2010)

Melo HVDC

8. Brazil (1976-2018)

FACTS (SVC & FSC)

Current Limiting Reactors

Neutral Grounding Reactors

Damping & Filter Reactors

Arc-Furnace Reactors

Laboratory Reactors

9. Scotland (2002)

FACTS (SVC)

10. France, Germany and Netherlands (2002-2018)

Damping & Filter Reactors

Neutral Grounding Reactors

11 Turkey (2008)

FACTS (SVC)

12. South Africa (1998-2018)

Current Limiting Reactors

Damping & Filter Reactors

13. South Korea (2014)

HVDC Smoothing Reactors

14. Thailand (2006-2018)

Damping & Filter Reactors

15. Malaysia (2002-2018)

Damping & Filter Reactors

16. Australia (2010-2018)

Shunt Reactors

Damping & Filter Reactors

Recommended Products & services

High Voltage Capacitors

Increase Capacity, Stability & Power Quality

GE Vernova's high voltage capacitors provide simple and reliable reactive power to improve system performance, quality and efficiency. They are designed and manufactured using advanced technology and high-quality materials, and are all-film dielectric units impregnated with biodegradable dielectric liquid.

High Voltage Capacitors

Increase Capacity, Stability & Power Quality

GE Vernova's high voltage capacitors provide simple and reliable reactive power to improve system performance, quality and efficiency. They are designed and manufactured using advanced technology and high-quality materials, and are all-film dielectric units impregnated with biodegradable dielectric liquid.

High voltage capacitor banks

GE Vernova provides solutions for high voltage PFC (Power Factor Control) and filtering. GE Vernova’s high voltage capacitor bank equipment is offered in three primary types of fusing schemes: internally fused, externally fused and fuseless. GE Vernova can analyze your network thoroughly and help you to choose the design that best fits your specific requirements.

Typical passive solutions

Shunt bank capacitor bank provided optionally with accessories including surge current limiting reactors and switches.

Detuned filter is a power factor solution for networks with harmonics. Series connected capacitor bank and reactor increase the impedance of the circuit at network harmonics reducing capacitor overload.

Tuned harmonic filter provides power factor solutions at fundamental frequency and filters harmonics at a specific frequency. Series connected capacitor bank and reactor create a low impedance path for specific network harmonic(s).

For more information on our shunt bank, detuned filter & tuned harmonic filter solutions, view the brochure and application guide.

Mechanically Switched Capacitor with Damped Network (MSCDN) mitigates undesired network resonances by adding a damping circuit in series with a capacitor bank. For more information view the brochure.

Open rack equipment

Open stack rack capacitor banks are applicable where a large amount of reactive power is required at high voltage. Capacitors and auxiliary equipment are installed in welded aluminum or galvanized steel racks and shipped ready for field installation.

Features:

- Rated power up to 600MVAr / rated voltage up to 800kV

- Rugged for corrosive environment and wild life protection

- Multiple fusing schemes (internal, external and fuseless)

- Multiple switching and protection options available

- Fast installation and quick return-on-investment

For more information view the brochure and application guide.

Pole mounted equipment

GE Vernova’s pole mounted capacitor products are pre-wired, factory assembled and shipped ready for installation with single-phase capacitor units. Racks are made of welded structural aluminum suitable for mounting switches, junction box, cable assembly, lightning arresters and/or potential transformers.

Features:

- Power range 150-3600 kVAR / voltage range 2.4-34.5 kV

- Oil or vacuum switching available

- 3, 6, 9, or 12 unit racks available

- Individual or group fusing available

- High current vacuum switch mounting capability

- Rugged for corrosive environment and wild life protection

For more information view the brochure and application guide.

Metal enclosed capacitor banks

GE Vernova’s metal enclosed capacitor banks provide modular small footprint solution for power factor controlling and harmonic filtering at medium voltages. Capacitors, reactors and auxiliary equipment are installed in a welded galvaneal enclosure and shipped ready for installation. Banks are designed to meet extreme conditions from marine conditions to desert and from artic to tropic.

Features:

- Voltages from 2.4kV through 38kV

- Power ratings up to 40MVAr in a single enclosure

- Oil or vacuum switching

- Up to 15 steps in a single bank

- Enclosure protection level up to IP56/NEMA 4X

- Protection, grounding, disconnect, & interlock options

- Compliant with ANSI, IEEE, IEC, NEC and NESC

For more information view the brochure.

Fixed medium voltage PFC

GE Vernova’s High Voltage WeatherTight (HWT) capacitor banks are suitable for use on primary circuits where small amounts of kVAR are required. They may be installed at various load centers or directly at the terminals of 2300 and 4000 volt motors. Equipment is suitable for indoor and outdoor applications.

Features:

- Low losses <0.2W/kVAr

- Voltage ratings up to 13.8kV, power ratings up to 900kVAr

- Blown fuse indication lights

- Rugged design for harsh environment

- Operating temperature -40°C to +46°C (-40°F to 115°F)

- Compliant with IEEE, IEC, CSA and NEMA

For more information view the brochure.

HVDC / FACTS applications

GE Vernova’s HV reactive power compensation solutions have extensive experience in FACTS and HVDC, with a large installation base on both. Needs for compensation and filtering equipment in these solutions vary depending on overall design of the equipment, and is typically a combination of different kinds of capacitor banks and filters including:

- Detuned filter capacitor bank

- Single, double or triple tuned filter bank

- High-pass filter

- C-type filter

- HV DC capacitor banks

Visit GE Vernova’s FACTS and HVDC webpages for more information on these solutions for challenges that the modern power grid faces today.

Surge protection capacitors

GE Vernova’s surge capacitors protect the winding insulation of medium voltage rotating machines and transformers exposed to transient overvoltage or surges. GE Vernova’s non-PCB power capacitor is an environmentally acceptable product with superior performance and reliability. GE Vernova’s protective capacitors contain an all film dielectric system and hermetically sealed bushings, which permits flexible mounting configurations.

Surge protection for:

- Large motors and generators

- Synchronous condensers

- Large motors

- Medium voltage switchgear and motor control centers

- Large transformers

- Shunt reactors

For more information view the brochure.

Features:

- Rated voltage up to 25kV

- Typical capacitance range 0.1-0.5µF

- 1- or 3-phase designs

- Time proven GE Vernova HAZY® film foil dielectric system

- Non-PCB insulating fluid

- Low loss fuseless design

- Provides turn-to-turn insulation protection by reducing steepness of wave fronts applied to or reflected within the machine

- Use in combination with GE Vernova TRANQUELL station arresters for optimum protection

Applications for power generation, renewable generation and offshore wind farms:

- Protection capacitors for generators

- Compensation and filtering inside the power plant

- Harmonic filters AC/DC, HVDC

- Current limiting reactors

- Shunt capacitor banks for AC/DC converter systems

- Mechanically switched capacitor banks with damping network

Applications for FACTS, HVDC, transmission substations and distribution networks:

- Series compensation

- STATCOMs

- SVCs

- Harmonic filters

- Shunt capacitor banks

- Transformer and reactor protection capacitors

- Pole top capacitors

- AC and DC capacitor banks (shunt, series, filter)

Applications for buildings and cities, oil and gas, and industry and infrastructure:

- Harmonic filters

- Active filters

- Shunt capacitor banks

- Protection capacitors for motors and generators

- Feeder substation filters

- Detuned capacitor banks

For PDF in Spanish click here

Manufacturing Excellence

GE Vernova manufacturing plants are highly automated digital factories that use the GE Vernova Predix platform for machine learning and modeling.

Clearwater, FL, USA

Our Clearwater Factory converts raw data to useful insights. Data from RFID and sensor enabled machines are converted to traceable CTQs, design specification and test results that provide useful information for engineering and modeling. Our Clearwater factory is ISO 9001 certified.

Products manufactured in Clearwater, FL:

- High voltage capacitor units and banks

- Induction heating and melting capacitors

- Low voltage capacitor units and banks

- Surge arresters

Itajubá, Brazil

Our Itajubá factory supplies a broad range of engineered equipment for all segments and commercial regions, by means of state-of-the-art machinery and design criteria, first class raw material, strict production and quality controls, and very experienced staff.

Products manufactured in Itajubá, Brazil:

- Air-core dry-type reactors

- High voltage capacitor units and banks

- High voltage harmonic filters

- AIS products (instrument transformers, circuit breakers, disconnectors and line traps)

References

GE Vernova provides HV capacitor solutions and support to +1,000 customers in 80 countries. With more than 50 years of experience, GE Vernova is an industry leader with its all-film, extended foil design and robust manufacturing process. Our capacitors are installed globally in a variety of environmental conditions including extreme temperatures, highly corrosive dessert and offshore environments, and high level seismic zones. Below are a selected representation of our projects, a complete reference list is available upon request.

1. Canada (2013)FSC, 735kV, 659MVAr, 60Hz |

2. USA (2014)Peterson Flats FSC |

3. USA (2010)Mojave Desert Shunt bank 533kV 226 & 170MVAr |

4. Brazil (2012)Rio Madeira HVDC |

5. Chile (2017)Sic Sing FSC |

6. Canada (2017 -2018)Lower Churchill HVDC |

7. Canada (2014)SVC, 315kV, -100/+300MVAr, 60Hz |

8. Scotland (2015)MSCDN 150kV 60MVAr |

9. Germany (2013 - 2018)MSCDNs |

10. Nigeria (2014)Kano Substation, Shunt bank 330kV 50MVAr |

11. Namibia (2016)C-type filter 220kV 40MVAr |

12. Russia (2007)Shunt bank 121kV 42MVAr |

13. Saudi Arabia (2016)Jeddah North SVC |

14. South Korea (2016)KEPCO HVDC |

15. Hong Kong/ China (2012)Shunt bank 145kV 100MVAr |

16. Australia (2015)Black Range FSC |

Recommended Products & services

CCV

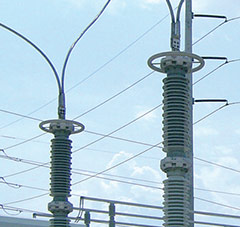

CVT and CC Coupling Capacitors up to 800 kV

In high and extra high voltage transmission systems, capacitor voltage transformers (CVTs) are used to provide potential outputs to metering instruments and protective relays. In addition, when equipped with carrier accessories, CVTs can be used for power line carrier (PLC) coupling.

CCV

CVT and CC Coupling Capacitors up to 800 kV

In high and extra high voltage transmission systems, capacitor voltage transformers (CVTs) are used to provide potential outputs to metering instruments and protective relays. In addition, when equipped with carrier accessories, CVTs can be used for power line carrier (PLC) coupling.

Recommended Products & services

OTCF

Coupling Capacitor Voltage Transformers up to 800 kV

In high and extra high voltage transmission systems, capacitor voltage transformers (CVTs) are used to provide potential outputs to metering instruments and protective relays. In addition, when equipped with carrier accessories, CVTs can be used for power line carrier (PLC) coupling.

OTCF

Coupling Capacitor Voltage Transformers up to 800 kV

In high and extra high voltage transmission systems, capacitor voltage transformers (CVTs) are used to provide potential outputs to metering instruments and protective relays. In addition, when equipped with carrier accessories, CVTs can be used for power line carrier (PLC) coupling.

Recommended Products & services

KOTEF

Oil-Insulated Combined CT/VT up to 420 kV

KOTEF utilizes the same components as the individual CTs and VTs. Both transformers are combined in a single metering unit and are available in porcelain or composite. The KOTEF combines the advantages and design features of the OSKF and OTEF lines.

KOTEF

Oil-Insulated Combined CT/VT up to 420 kV

KOTEF utilizes the same components as the individual CTs and VTs. Both transformers are combined in a single metering unit and are available in porcelain or composite. The KOTEF combines the advantages and design features of the OSKF and OTEF lines.