GE Vernova’s Technical Institute works with you to build the training plan best adapted to your teams’ needs and provides training through advanced methodologies with e-learning, theoretical courses, hands-on training on real size equipment or competence development programs.

Improved efficiency and safety at work

Training is the most efficient tool to develop know-how and enhance employee performance.

Better technical expertise

As GE Vernova develops and manufactures leading transmission products and solutions, its experienced trainers benefit from engineering and maintenance service expertise.

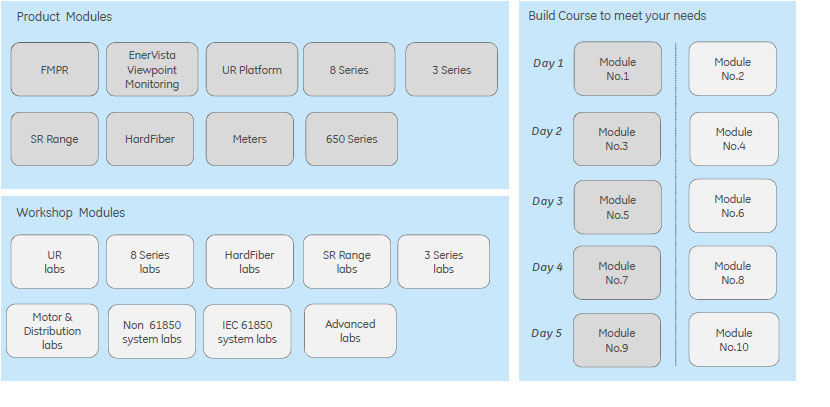

Training perfectly adapted to the audience

With more than 200 training courses in different languages, you will find one adapted to the trainee level of knowledge (operators, managers, engineers…) and objectives. If not, you can ask for customized training!

Industry experience

With more than 13,500 trainee days per year and 30 years of experience in training, our Technical Institutes, all located in our manufacturing sites, provide hands-on training using real equipment and sandbox for practical application.

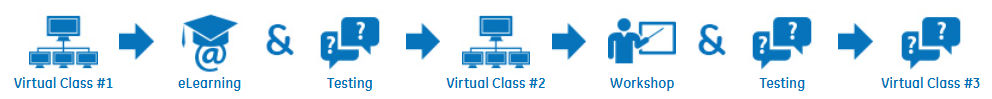

State-of-the-art methods and tools

To better answer your needs, choose from a large range of training methods: tutored e-learning, classroom course, hands-on, set curriculums, 3D modules and competence development.

The latest knowledge content

We continuously improve existing training modules and develop new ones according to local regulations, new technologies, products and solutions.