Overview

A Suite of Digital Technologies to Collect Data

The collection of required asset condition data from the field on a large scale for GE Vernova and 3rd party electrical equipment is a key step in building a robust Asset Performance Management strategy. Grid Services specialists are constantly evaluating and implementing new innovative inspection technologies applying strict processes and methods. The digital inspections methods are designed to improve the efficiency of data collection, oil analysis and online monitoring. All new approaches to capture data are integrated into the EnergyAPM ecosystem for automatic data transfer.

Putting your data to work with GE Vernova's multi-disciplinary team of consulting experts

Product Reliability Engineers

Assess the existing asset data collected and recommend new digital data collection based on criticality, age and operational environment

Telecommunications Engineers

Evaluate data standardization needs and propose a safe data exchange architecture

APM Specialists

Help to define the Asset Performance Management (APM) system taxonomy and harmonize it with the other enterprise applications

Connected Worker

Site inspections are supported by a well-defined methodology resulting from decades of experience in servicing power equipment and by a set of advanced digital tools ensuring data quality and rapid troubleshooting. GE Vernova field workers are connected:

DIGITAL INSPECTION APP

GE Vernova’s Field Inspection Tool (EnergyAPM FIT) is a tablet application designed by T&D maintenance specialists supporting safe, efficient and high-quality inspections.

- Standardized and normalized data are automatically shared in real time across the organization, minimizing administrative work and risk of error.

- Combined with the back-office application and a wide library of templates for various asset types, the inspection form library can be adapted to a specific application, dispatch work and rapidly generate reports.

- EnergyAPM FIT is an option of the GE Vernova Asset Performance Management program enriching EnergyAPM models and analytics.

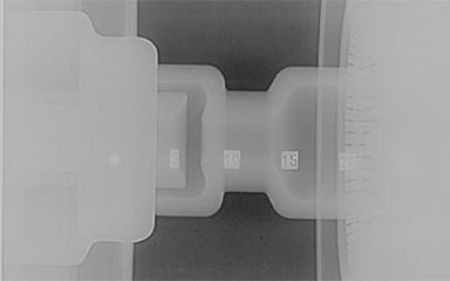

Advanced Non-Intrusive Inspections for GIS, Transformer and Circuit Breakers

Technologies are available to assess various components without the need to open the asset reducing outage time and risks.

Methods include:

- Dynamic Contact Resistance Measurement to detect arcing contact wear and over-travel condition

- X-Ray inspection to evaluate the condition of main arcing and moving components

- Vibration Monitoring to detect operating mechanism defect

Online Monitoring for Critical Asset

Multi Gas Transformer DGA

Solutions to monitor up to 9 fault gas and moisture

Switchgear Monitoring

Solutions for SF6 gas and partial discharge monitoring

Single Gas Transformer DGA

Cost effective solutions for transformer monitoring

Transformer Monitoring

Holistic but modular continuous on-line enhanced monitoring solutions

Ultra High Frequency Sensors

Measure GIS partial discharge to assess the condition of the SF6 or g3 insulation

GridBeats™ APM

Asset Performance Management Solutions