Multilin 369 - Legacy

Integrated protection and control for medium sized AC motors

Manufacturing for the 369 has been discontinued. As an alternative, please refer to 859.

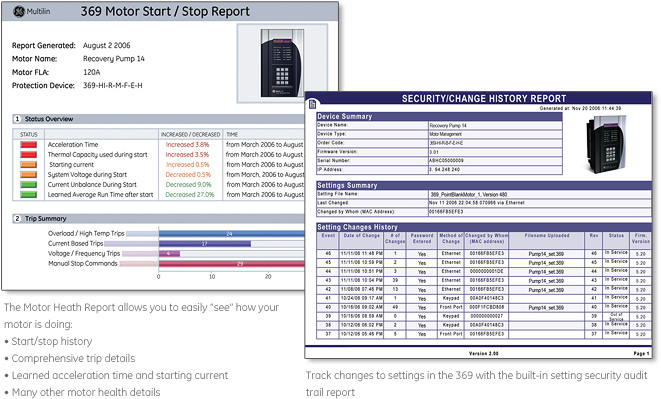

Designed for medium voltage motors, the 369 delivers simple setup configuration through the use of the Motor Settings Auto-Configurator, advanced graphical diagnostics with the Motor Health Report, comprehensive communications with multiple communication options and complete traceability of all setting changes with the Security Setting Change History Report, providing unparalleled motor protection for medium sized AC motors.

Key Benefits

- Enhanced Thermal Model

- Complete Asset monitoring

- Enhanced reporting

- Reduce troubleshooting time and maintenance costs

- Multiple communication protocols

- Simplified programming with the EnerVista™ 369 Motor Settings Auto-Configurator

- Optional Conformal coating

- Field upgradeable settings and firmware

- Suitable for hazardous locations

- Installation flexibility

- Safe and reliable motor re-start on “Down Hole” pump applications

- User definable parameters and data size for DeviceNet polling

- User definable parameters and data size for Profibus DPV1 cyclic data

- Motor learned data on historical start characteristics

Applications

- Protection and control for medium sized AC motors

- “Down Hole” pump applications

- Suitable for applications involving Variable Frequency Drives

- Two Speed motor application

Multilin 369 - Legacy

Integrated protection and control for medium sized AC motors

Manufacturing for the 369 has been discontinued. As an alternative, please refer to 859.

Designed for medium voltage motors, the 369 delivers simple setup configuration through the use of the Motor Settings Auto-Configurator, advanced graphical diagnostics with the Motor Health Report, comprehensive communications with multiple communication options and complete traceability of all setting changes with the Security Setting Change History Report, providing unparalleled motor protection for medium sized AC motors.

Key Benefits

- Enhanced Thermal Model

- Complete Asset monitoring

- Enhanced reporting

- Reduce troubleshooting time and maintenance costs

- Multiple communication protocols

- Simplified programming with the EnerVista™ 369 Motor Settings Auto-Configurator

- Optional Conformal coating

- Field upgradeable settings and firmware

- Suitable for hazardous locations

- Installation flexibility

- Safe and reliable motor re-start on “Down Hole” pump applications

- User definable parameters and data size for DeviceNet polling

- User definable parameters and data size for Profibus DPV1 cyclic data

- Motor learned data on historical start characteristics

Applications

- Protection and control for medium sized AC motors

- “Down Hole” pump applications

- Suitable for applications involving Variable Frequency Drives

- Two Speed motor application

| |||||||||||||||||||

| ||||||||||||

| ||||||||||||

|

| ||||||||||||

| A front RS232 port is provided for downloading setpoints and interrogating the relay using the EnerVista™ 369. Three independent rear RS485 ports offer the customer flexibility and performance for their communication network. The 369 can communicate at baud rates up to 19,200 bps using the industry standard Modbus® RTU protocol. Fiber optic (option F) Profibus interface (option P), DeviceNet (option D), and Ethernet (option E) ports are also available. The optional direct connect RJ45 Ethernet port can be used to connect the 369 to 10 Mbps Ethernet networks. The communication system of the 369 is designed to allow simultaneous communication via all ports. Using Ethernet as the physical media to integrate the 369 to Local or Wide Area Networks replaces a multipoint wired network (e.g., serial Modbus®), and eliminates expensive leased or dial-up connections, reducing operating costs. | ||||||||||||

|

| EnerVista™ Software | ||

The EnerVista™ Suite is an industry leading set of software programs that will simplify every aspect of using the 369 relay. Tools to monitor the status of the motor, maintain the relay, and integrate information measured by the 369 into HMI or SCADA monitoring systems are available. Also provided are the utilities to analyze the cause of faults and system disturbances using the powerful waveform and Sequence of Event viewers that come with the EnerVista™ 369 Setup Software that is included with each relay. Learn More Motor Settings Auto-Configurator Automatically generate a complete settings file, eliminating the need to manually program hundreds of individual protection settings. |  |

| ||||

|