SUPERBUTE™

Current and Voltage Transformers up to 69 kV

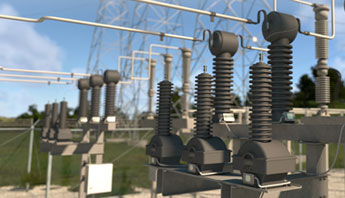

SUPERBUTE dry-type instrument transformers are engineered and rigorously tested to provide a measurable difference in reliability and durability. Since the very first unit produced in 1955, SUPERBUTE instrument transformers have provided utilities with a number of benefits for enhanced safety and a lower total cost of ownership. SUPERBUTE is designed to meet IEEE C57.13 standards and ANSI standard mounting provisions, terminals, and construction.

GE Vernova’s SUPERBUTE family of products supports system voltages up to and including 69 kV. The unique design of the SUPERBUTE family addresses the challenges with traditional voltage and current instrument transformers.

Features

GE Vernova’s SUPERBUTE product range consists of Inductive Voltage Transformers and Current Transformers:

- Indoor and outdoor designs

- Rated voltages up to 69 kV

- Rated basic insulation levels (BIL) up to 350 kV

- Relay class ratings up to T800

- Standard & Special High Accuracy metering classes

Applications

GE Vernova’s SUPERBUTE product range includes specifications suitable for a wide range of revenue metering, protection and control applications. Common uses include:

- Substation metering and relaying

- Primary metering cabinets

- Pole-top primary metering assemblies

- Control power for reclosers, capacitors, and other distribution equipment

- Current of voltage sensing for switchgear, circuit breakers, and other control equipment

SUPERBUTE™

Current and Voltage Transformers up to 69 kV

SUPERBUTE dry-type instrument transformers are engineered and rigorously tested to provide a measurable difference in reliability and durability. Since the very first unit produced in 1955, SUPERBUTE instrument transformers have provided utilities with a number of benefits for enhanced safety and a lower total cost of ownership. SUPERBUTE is designed to meet IEEE C57.13 standards and ANSI standard mounting provisions, terminals, and construction.

GE Vernova’s SUPERBUTE family of products supports system voltages up to and including 69 kV. The unique design of the SUPERBUTE family addresses the challenges with traditional voltage and current instrument transformers.

Features

GE Vernova’s SUPERBUTE product range consists of Inductive Voltage Transformers and Current Transformers:

- Indoor and outdoor designs

- Rated voltages up to 69 kV

- Rated basic insulation levels (BIL) up to 350 kV

- Relay class ratings up to T800

- Standard & Special High Accuracy metering classes

Applications

GE Vernova’s SUPERBUTE product range includes specifications suitable for a wide range of revenue metering, protection and control applications. Common uses include:

- Substation metering and relaying

- Primary metering cabinets

- Pole-top primary metering assemblies

- Control power for reclosers, capacitors, and other distribution equipment

- Current of voltage sensing for switchgear, circuit breakers, and other control equipment

Key Benefits

Distribution class SUPERBUTE offers compact designs for more efficient application to solid-state metering and other modern installations.

Distribution class SUPERBUTE offers compact designs for more efficient application to solid-state metering and other modern installations.

Station class SUPERBUTE offers higher burden, higher thermal rating, and extra creep distance for substations or installations where higher ratings are required.

Station class SUPERBUTE offers higher burden, higher thermal rating, and extra creep distance for substations or installations where higher ratings are required.

Longer Product Life

Field studies and accelerated life testing has shown an average operating life of more than 40 years, with reliability measures 3 times better than published industry benchmarks

Enhanced Safety

Internal insulation is made from epoxy resin which is encapsulated in tough, elastic butyl rubber, dampening and minimizing the impact of high energy events

Environmentally Friendly & Minimum Maintenance

Unique dry-type construction ends oil leakage problems, eliminates breakage and vandalism issues, and does not support combustion

Lower Total Cost of Ownership

The dry-type design eliminates the need for oil testing or filtering and allows for a compact design which facilitates mounting flexibility for more economical installations such as on existing steel structures, inside a cabinet, or on a pole

Fast Delivery

Extensive vertical integration within the factory allows for standard lead times of 4-6 weeks, nearly half the industry average

Tough & Resilient Insulation

GE Vernova’s proprietary formula of non-arc tracking butyl rubber showed no carbonization after 4,000 hours in salt-fog testing, compared to standard butyl rubber which failed after 107 hours or standard porcelain which failed after 400 hours under the sa

GE Vernova’s proprietary formula of non-arc tracking butyl rubber showed no carbonization after 4,000 hours in salt-fog testing, compared to standard butyl rubber which failed after 107 hours or standard porcelain which failed after 400 hours under the sa

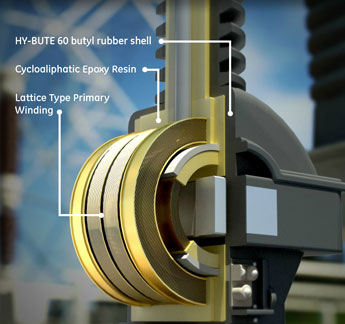

HY-BUTE 60™ butyl rubber as the external insulation

The outer shell of SUPERBUTE transformers are made with GE Vernova’s proprietary formula of butyl rubber, which is called HY-BUTE 60. This material adds the following timeless advantages over epoxy resins or porcelains designs:

- Encapsulating the unit with a tough, elastic rubber provides an inherent safety advantage as it dampens the severity of any potential failure

- Unique chemistry provides for non-arc tracking surface, significantly reducing risk of failure from flashover

- Legendary durability as this material does not easily chip, crack, or shear

- Will not stress crack due to the external environment, even in extreme conditions such as -50°C

- Maintains hydrophobicity over the life of the transformer

- Does not support combustion

- Does not oxidize or corrode

Cross section of a JVS350 station-class voltage transformer showing Epoxy encapsulated with HY-BUTE 60 butyl rubber shell

Cross section of a JVS350 station-class voltage transformer showing Epoxy encapsulated with HY-BUTE 60 butyl rubber shell

Epoxy as the internal insulation

Epoxy takes the place of oil as the internal insulation and winding impregnation. The advantage of this design includes:

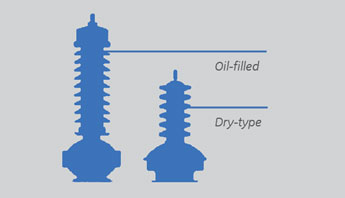

- Reduced footprint with a compact design with up to 30% less height than the leading oil-filled designs

- High tensile strength which allows for mounting in any position including vertical, horizontal, upside down, or at any angle

- Environmentally friendly design eliminates hidden costs associated with traditional liquid-filled designs such as:

- oil-leakage problems

- oil filtering or testing

- construction requirements for a large installation space or dedicated support structure

Superior Design Features

SUPERBUTE Advantage: Superior primary winding design and extra creep distance ensure accurate, reliable performance in harsh conditions

SUPERBUTE instrument transformers are designed for quality and reliability with features engineered to withstand high voltage stresses and extreme environmental conditions, while delivering the highest accuracies possible, all within a compact design. The result is a reliable, long-lasting, easy to handle design that ultimately lowers total cost of ownership.

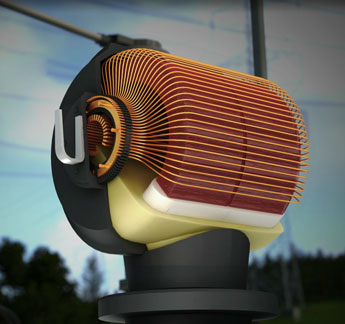

Lattice-type winding in a JVS350 station-class VT

Lattice-type winding in a JVS350 station-class VT

Multi-gap type primary in a JKW350 station-class CT

Multi-gap type primary in a JKW350 station-class CT

Lattice-type windings for voltage transformer

Originally patented by GE Vernova, lattice-type windings have precise controlled positioning and distribution of each turn to reduce maximum voltage stress within the winding. This unique design also minimizes the possibility of partial discharges within the winding. The coil configuration, and the outer electrostatic shields distribute steep voltage fronts across the coil to reduce concentration of stress.

Built-in surge protection for current transformers

A unique multi-gap type primary by-pass on current transformers 600 amps and below protects windings during line disturbances or steep current wave fronts. The gaps are factory adjusted to fire at 5000-7500 crest volts, thereby by-passing surge currents up to 100 times rated, which could otherwise result in excessive voltages across the primary winding.

High accuracy, extended range ratings for current transformers

The use of high accuracy instrument transformers with solid-state metering allows for improved billing accuracy and/or the potential to reduce inventory requirements. GE Vernova offers high accuracy and extended range ratings which meet the accuracy needed for these applications. Since introducing the first dry-type high-accuracy transformer solution in 1991, GE Vernova’s high accuracy product line has grown to a portfolio that includes a wide variety of voltage classes up to and including 69 kV.

Compact size & mounting flexibility

SUPERBUTE transformers require up to 30% less height and up to 40% less floor space compared to the leading oil-filled designs, and can be mounted in any position. This allows substation design flexibility including mounting on a substation steel structure or a pole.

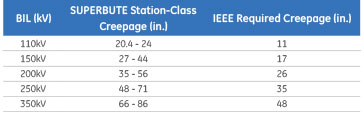

Extra creep & strike

Even with 30% less height, standard units can be used in environmentally severe conditions and in high altitude (10,000ft) applications. Station class units have creep distances that exceed the requirements for even the next-level voltage class.

SUPERBUTE station-class creepage distances versus IEEE C57.13-2008</em> <em>required levels, by system voltage

SUPERBUTE station-class creepage distances versus IEEE C57.13-2008</em> <em>required levels, by system voltage

SUPERBUTE transformers are more compact and lower profile compared to the lead liquid filled transformers

SUPERBUTE transformers are more compact and lower profile compared to the lead liquid filled transformers

Voltage Transformers

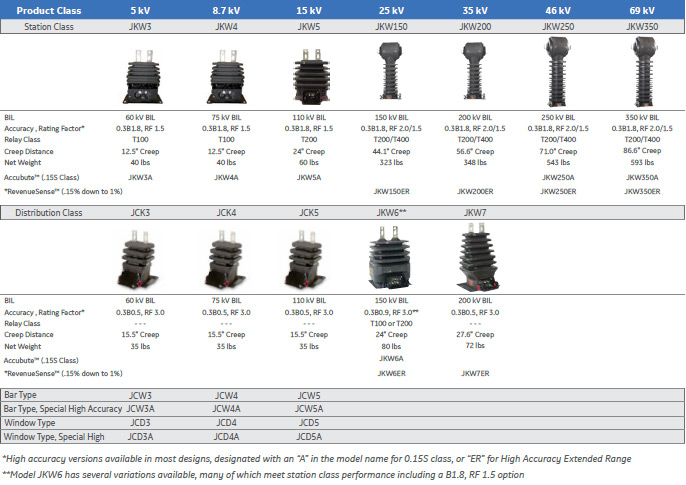

SUPERBUTE Product Overview: Inductive Voltage Transformers

Outdoor Voltage Transformers: Outdoor voltage transformers are available at 5-69 kV and 60-350 kV BIL. These units are offered in two distinct sizes for efficient sizing:

- Station class: Higher burden, higher thermal rating, and extra creep distance for metering and/or relaying applications in substations or installations where higher ratings are required such as high altitude or high contamination locations.

- Distribution class: Compact designs, with lighter burden and thermal rating for more efficient application to solid-state metering and other modern relay and control power installations.

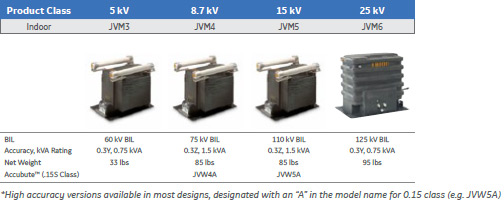

Indoor Voltage Transformers: Indoor Voltage Transformers are available at 5-25 kV system voltage and 60-200 kV BIL.

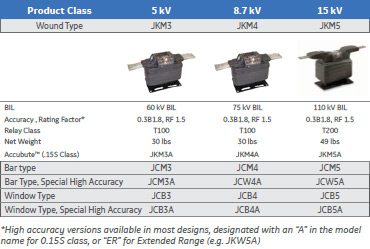

Current Transformers

SUPERBUTE Product Overview: Current Transformers

Outdoor Current Transformers: Outdoor current transformers are available in Bar-Type and Window-Type styles, 5-15 kV, 60 kV-110 kV BIL, up to 4000 A. Outdoor wound-type current transformers (CTs) are available 5-69 kV, 60-350 kV BIL, up to 1200 A. Wound-type units are available in two distinct sizes:

- Station class: Station class CT’s have a versatile design that is suitable for metering and/or relaying applications. Units are larger in size, have additional creep distance, and are rated for heavier metering burdens.

- Distribution class: Distribution class CT’s are more compact and are designed specifically for maximum efficiency in solid-state revenue metering applications. These CT’s generally do not have a relay rating.

Outdoor current transformers are also available in Bar-Type and Window-Type styles, 5-15 kV, 60 kV-110 kV BIL, up to 4000A.

Indoor Current Transformers: Indoor current transformers are available 5-15 kV system voltage and 60-150 kV BIL. Product types include wound type up to 1200 A, and window-type or bar-type up to 4000 A.

Combined CT/VT

Outdoor CT/VT combo: Designed for outdoor service, a combination voltage transformer (VT) and current transformer (CT) is typically used for primary metering applications. GE Vernova’s RevenueSense™ CT design provides 0.15 accuracy from 1% of rated current through rating factor.

Why a combo unit

- Safety – fewer HV connections

- Savings – reduced field labor (1/2 the # of units)

- Simplification – fewer items to stock

GE Vernova unique features

- HY-BUTE 60™ Butyl Rubber

- Dual primary voltage options

- RevenueSense™ CT (0.15% accuracy down to 1%)

- Lattice style primary winding VT

- Proven non-arc tracking design

- Meets IEEE C57.13-2016 heavy pollution standards