DT1-245P

Dead Tank Circuit Breaker for 245 kV

GE’s DT series of dead tank circuit breakers are characterized by advanced self-blast interrupters, leak-resistant, cast aluminum enclosures and durable, low-energy spring-operated mechanisms. More than 100,000 circuit breakers with self-blast interrupters and FK spring-operated mechanisms have been in service since 1989.

The DT1-245P is available for single pole or for the three-pole gang operation. By utilizing tank heaters, the DT1-245P can be installed in regions with temperatures as low as -60°C. The field-proven interrupter chamber with double-motion technology utilizes the energy-optimized, self-blast principle which dramatically reduces the mechanical stress in the chamber, enabling a higher interrupting capability with a lower operational energy requirement.

DT1-245P

Dead Tank Circuit Breaker for 245 kV

GE’s DT series of dead tank circuit breakers are characterized by advanced self-blast interrupters, leak-resistant, cast aluminum enclosures and durable, low-energy spring-operated mechanisms. More than 100,000 circuit breakers with self-blast interrupters and FK spring-operated mechanisms have been in service since 1989.

The DT1-245P is available for single pole or for the three-pole gang operation. By utilizing tank heaters, the DT1-245P can be installed in regions with temperatures as low as -60°C. The field-proven interrupter chamber with double-motion technology utilizes the energy-optimized, self-blast principle which dramatically reduces the mechanical stress in the chamber, enabling a higher interrupting capability with a lower operational energy requirement.

Spring-spring mechanism

The reduced energy requirements of the breaking chamber allows for the utilization of the world class FK spring-spring mechanism. The combination of the proven FK drive mechanism and interrupter technology results in a significant reduction of reaction forces, thus reducing foundation design requirements.

Gas Tightness Guarantee

GE leads the industry in SF6 gas tightness testing technology including seals, castings, and plumbing systems. Each breaker is factory tested using GE’s proprietary gas tightness testing system which provides measurable, quantifiable test results on the breaker in its fully assembled, as-shipped condition.

Certified Quality

GE designs, manufactures, tests and delivers its circuit breakers in accordance with the latest IEEE/ANSI and IEC standards, maintaining a quality assurance system according to ISO-9011 and ISO-14001 certifications. The center of excellence for dead tank circuit breakers is located in Charleroi, PA.

Installation and Maintenance

The DT1-245 series is factory tested and prepared for shipment with bushings assembled and prefilled with SF6 gas, therefore the on-site installation requires only a few simple steps without requiring any special tools. The DT1-245 circuit breaker range has lower maintenance costs and requirements, thanks to an engineering and design philosophy that has focused on these key needs since the inception of the development process.

Specifications

| IEEE/ANSI | IEC | Value | Units |

| Rated maximum voltage | Rated voltage | 245 | kV |

| Rated power frequency | Rated frequency | 50/60 | Hz |

| Dry withstand | At power frequency,dry | 425/460 | kV |

| Rated lightning impulse withstand voltage | At lightning impulse | 900/1,050 | kV |

| Rated chopped wave impulse voltage 2us | 1,160 | kV | |

| Rated continuous current | Rated normal current | 3,000/4,000 | A |

| Rated short-circuit current | Rated short-circuit breaking current | 40 | kA |

| Rated closing,latching and short time carrying | 104 | kA | |

| Rated short-circuit making current | 104 | kA | |

| Rated capacitance switching* | |||

| Rated interrupting time | 3 | cycles | |

| Rated break time | 50 | ms | |

| Rated standard operating duty | O-CO-15s-CO O-0.3s-CO-180s-CO | ||

| *Rating available upoon request **Contact Grid Solutions for special purpose, high TRV, high X/R or other ratings requirements. | |||

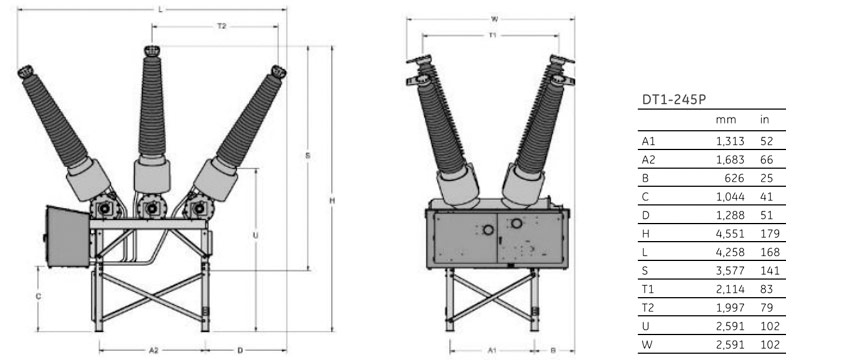

Drawings