Multilin DGCR - Legacy

Advanced Distribution Automation Controller

Manufacturing for this product has been discontinued. Please contact us to discuss alternatives.

The Multilin DGCR is an advanced Controller for detection of faults and controlling overhead reclosers. The Multilin DGCR is compatible with many traditional and magnetic actuator reclosers and provides a great degree of flexibility in integrating with FDIR systems.

Multilin DGCR - Legacy

Advanced Distribution Automation Controller

Manufacturing for this product has been discontinued. Please contact us to discuss alternatives.

The Multilin DGCR is an advanced Controller for detection of faults and controlling overhead reclosers. The Multilin DGCR is compatible with many traditional and magnetic actuator reclosers and provides a great degree of flexibility in integrating with FDIR systems.

Key Features

- Auto/manual or Local/Remote

- Cold Load Pickup

- Phase IOC detection

- Phase TOC detection

- Neutral TOC detection

- Over Voltage

- Under Voltage

- Voltage Unbalance

FDIR/FLISR

A key driver and measurement of utility effectiveness is in the reliability of power to its customers. As many faults on overhead distribution lines are transient in nature, reclosing at the substation and installation of mid-line reclosers./switches can improve a utilities SAIDI reliability index by up to 24%.

When permanent faults occur on overhead lines, having feeders with increasing degrees or automation can greatly enhance distribution grid reliability and reduce restoration of unfaulted segments from several hours to a few seconds or minutes. A key component of these automation schemes is intelligent controllers that can integrate with FDIR systems through sharing local information and accepting control commands.

Recloser Control

Robust Design

Based on GE Vernova's proven controller platform with tens of thousands of units installed globally, the Multilin DGCR undergoes extensive Accelerated Life Testing (ALT) and Highly Accelerated Life Testing (HALT) to validate accurate functionality under specified conditions and to ensure accurate performance in extreme operating conditions and harsh environments.

Modes of Operation

The Multilin DGCR Recloser controller provides two modes of operation:

- Remote mode

- Local mode

The Multilin DGCR recloser controller measures three phase voltages and currents, and based on the measurements, manages Auto-Recloser functionality:

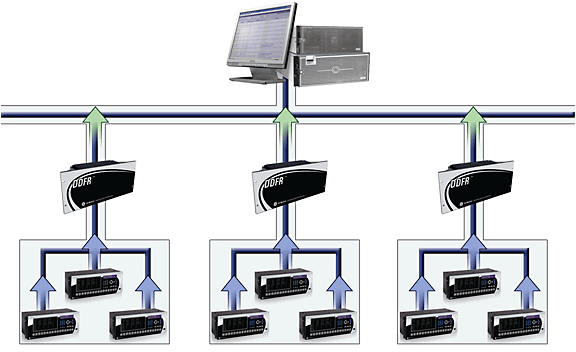

Typical Application of Distribution Automation solutions

(Centralied Volt/VAR control (CVVC) & Fault Detection, Isolation & Restoration(FDIR))

Above depicts a simplified distribution network and two key distribution automation solutions driving grid optimization, efficiency and reliability

Above depicts a simplified distribution network and two key distribution automation solutions driving grid optimization, efficiency and reliability

Key Features

- Multiple setpoint groups

- Expandable inputs and outputs for advanced applications

- Customized automation schemes using FlexLogic™

Automation & Control

The Multilin DGCR offers powerful I/O and programmable logic (FlexLogic™) options for advanced automation and control, reducing the need and costs associated with additional programmable controllers or discrete control devices.

Remote Control

For both operational efficiency and reliability reasons, the Multilin DGCR provides remote control for operating switchgear. The Multilin DGCR is capable of providing both local and manual control of the switchgear.

Set Point Group Control

The Multilin DGCR has three identical set point groups. The activation of the group can be done either from the HMI or via a digital input.

Virtual Inputs and Outputs

The Multilin DGCR provides 32 virtual inputs and 32 virtual outputs that provide users with the ability to send commands to the device. The Multilin DGCR can accept commands from SCADA, through the front HMI, or front USB port to issue commands such as close or open.

Command Setting

The Multilin DGCR has the ability to force commands from the menu structure. This can also be achieved via the EnerVista™ software that runs on a PC. This simulation ensures that the close and open commands can be safely issued from a distance without using the HMI.

FlexLogic™

FlexLogic in the Multilin DGCR provides the ability to create customized control schemes. This minimizes the need and costs associated with auxiliary components and wiring.

Key Features

- Metering - current, voltage, power, energy,frequency, PF, Harmonics

- Event Recorder - Up to 256 time tagged events

- Statistics & counters

- Enhanced system diagnostics & reporting

Metering & Monitoring

The Multilin DGCR provides high accuracy metering and recording of all AC signals, measuring the following key parameters:

- Phase-Ground Voltages (kV)

- Phase to phase Voltages (kV)

- Positive, Negative, Zero Sequence Voltage

- Phase A, B, and C currents (A)

- Positive, Negative, Zero Sequence Current Ground Current (A)

- 3-Phase Active power (KW)

- 3-Phase Reactive power (KVar)

- 3-Phase Apparent Power

- Power Factor (Lag or Lead)

- Pos. & Neg. (Import & Export) Real Energy (kWh)

- Pos. & Neg. (Import & Export) Reactive Energy (kVarh)

- 2nd to 8th harmonic up to 20% – for current

- 2nd to 8th harmonic up to 20% – for voltage

- THD in 20% – for current

- THD in 20% – for voltage

These data points can be easily integrated into a customer's database for seamless viewing through a SCADA or DMS system like GE Vernova's PowerOn or GeNe.

Statistics & Counters

- Trip Counter

- Open Counter

- Close Counter

- KI²t Phase A Counter

- KI²t Phase B Counter

- KI²t Phase C Counter

- Total Close/Open Operation

Maintenance Elements

The maintenance elements in the Multilin DGCR provides alarms to the system based on the maximum number of closing/opening executed commands per period of time and I²t measurements per feeder.

Event recorder

The Multilin DGCR provides an integrated event recorder and detailed diagnostic features. The sequence of events recorder offers the following features:

- Up to 256 consecutive events stored

- Enable or disable, operate and dropout events by set points

- Phase voltage/current and power metering shot is also included and stored at each event

Advanced Device Health Diagnostics

Comprehensive device health diagnostic tests are performed by the Multilin DGCR during startup and continuously at runtime to test its own major functions and critical hardware User Interface.

Key Features

Networking Interface

- Two Wire RS485

- Multiple Protocols (Modbus®, DNP3.0)

- Optional wireless communications (radio or cellular)

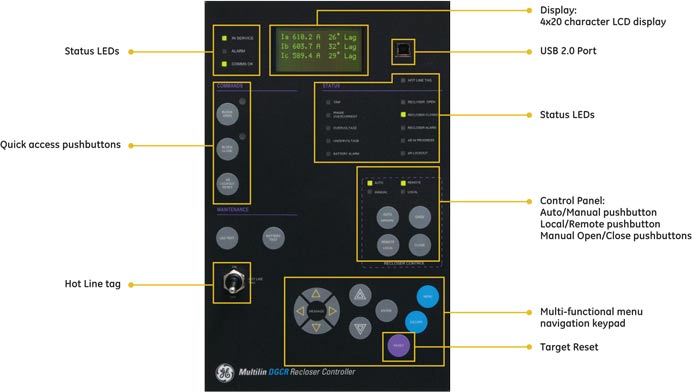

User Interface

- Front panel USB por

- 4 line HMI Display

- 20 System status LED’s

Key Features

- 4-Level device security to maintain authorized access only

- Simplified device configuration software tool and industry leading suite of software tools to manage and maintain Multilin devices.

Security

The DGCR and associated software tools provide a suite of security features that ensure only approved personnel can make changes to the device configuration or execute operational commands.

Password Security

The DGCR offers multiple levels of password security to limit access control based on settings or command levels. There are four levels of password security provided:

- Local Settings Access

- Local Control Access

- Remote Settings Access

- Remote Control Access

Local Access refers to users making changes using the front USB serial port and the HMI. Remote Access refers to users making changes using the rear RS485 port.

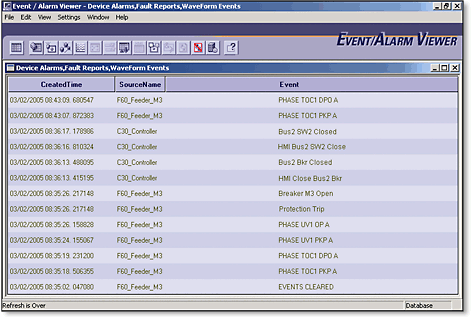

EnerVista™ Software

The EnerVista™ Suite is an industry-leading set of software programs that simplifies every aspect of using the DGCR Voltage Regulator Conroller. The EnerVista™ suite provides all the tools to monitor the status of the protected asset, maintain the controller, and integrate information measured by the DGCR into SCADA or the DMS monitoring systems. The ability to easily view sequence of events is an integral part of the setup software, as postmortem event analysis is critical to proper system operation. Learn More

Recommended Products & services

DGCM Field RTU - Legacy

Manufacturing for this product has been discontinued. As an alternative, please refer to the iBox.

DGCM Field RTU - Legacy

Manufacturing for this product has been discontinued. As an alternative, please refer to the iBox.

Fault/Level Detections

Effective fault isolation is a key feature for grid reliability. The Multilin DGCM provides early warning for downstream overcurrent and earth faults. It can be programmed to isolate a faulted segment, either independently or from the remote. The Multilin DGCM also offers control, monitoring and diagnostics in one integrated, efficient design.

Overcurrent Protection

Instantaneous and time overcurrent functions are available for phase, neutral and negative sequence currents. A variety of time curves are provided, including IEEE/ANSI, IEC A/B/C/long time inverse/short time inverse, definite time and user-programmable curves.

Cold Load Pickup

The Multilin DGCM can be programmed to block instantaneous overcurrent elements, and raise the pickup time of overcurrent elements, when a cold load condition is detected. The cold load condition is detected during the closing of the breaker on a feeder that has been de-energized for a long time. The feeder inrush and motor accelerating currents during breaker closing may be above some overcurrent protection settings.

Overvoltage (OV) Detection

The phase OV protection guards voltage sensitive feeder loads and circuits against sustained OV conditions. It generates alarms when the voltage exceeds the selected voltage level for the specified time delay.

Undervoltage (UV) Detection

The phase UV detection alerts utilities against sustained UV conditions. The UV detector generates an alarm when the voltage drops below the selected voltage level after a specified time delay.

Power Loss

The Multilin DGCM can detect a power loss condition in each phase of the power distribution line. Open/close commands are blocked, unless currents and voltages of each phase fall below minimum set values.

Application Overview

Metering & Monitoring

The Multilin DGCM provides high accuracy metering and recording of all AC signals, measuring the following key parameters:

Basic Measurements

- Current: Ia, Ib, Ic, In

- Phase-to-phase and phase-to-ground voltages for bus and line: Van, Vbn, Vcn, Vbb, Vab, Vbc, Vca

- Active power (per-phase and total): Wa, Wb, Wc, W

- Reactive power (per-phase and total): VARa, VARb, VARc, VAR

- Total active, reactive and apparent energy: MWh, MVARh, MVAh

- Power factor (per-phase and total)

- Frequency

Power Quality Measurements

- Voltage sag/swell

- Current unbalance

- Demand: voltage, current, active power, apparent power, energy, temperature

- 2nd to 15th harmonic for current

- 2nd to 15th harmonic for voltage

- THD in 20% for current

- THD in 20% for voltage

Data Management & Diagnostic

Event Recorder

To enable more effective distribution, post fault analysis and troubleshooting, the Multilin DGCM provides an integrated event recorder and detailed diagnostic features. The event recorder offers:

• Storage for up to 1024 consecutive events

Trending and Data Logging

The Multilin DGCM provides a 200 channel RMS recorder for advanced disturbance diagnostic features.

The Multilin DGCM data logger helps in better understanding the analog channel behavior, by sampling at a selectable time interval rate of 1 to 60 minutes.

The Multilin DGCM event recorder enables users to analyze the sequence of events . Each event is stored with the event number, date, time and analog data of interest.

The Multilin DGCM event recorder enables users to analyze the sequence of events . Each event is stored with the event number, date, time and analog data of interest.

Communications

The Multilin DGCM utilizes industry standard communications technologies, making it one of easiest and flexible controllers to use and integrate into new and existing SCADA or DMS infrastructures.

Multiple Protocol Support

Multiple communication ports and protocols allow for remote control and easy access to device and system information. All communication ports are capable of simultaneous communications.

Simultaneous industry standard protocols supported:

- DNP 3.0 – Serial and Ethernet

- Modbus Serial and Ethernet

- IEC 60870-5-104

Integrated Cellular

The Multilin DGCM’s integrated cellular modem eliminates the need for external wireless devices, which reduces infrastructure costs.

Several options for MDS™ radios when purchased with enclosure:

- MDS iNET-II

- MDS TransNet

Software

Software and Configuration

The EnerVista Suite is an industry-leading set of software programs that simplifies every aspect of using the Multilin DGCM. EnerVista provides the tools to monitor the status of the protected asset, maintain the controller and integrate information measured by the Multilin DGCM into SCADA or DMS monitoring systems.

EnerVista Launchpad

EnerVista Launchpad is a powerful software package that provides users with of the setup and support tools needed for configuring and maintaining GE Vernova’s Multilin products. The setup software within Launchpad allows the configuration of devices in real-time, by communicating via serial, Ethernet or modem connections, or offline, by creating device setting files to be sent to devices at a later time.

Recommended Products & services

Capacitor Bank Controller - Legacy

Manufacturing for this product has been discontinued. Please contact us if you have any inquiries.

Capacitor Bank Controller - Legacy

Manufacturing for this product has been discontinued. Please contact us if you have any inquiries.

Key Features

- Auto/Manual or Local/Remote control

- Automatic control based on Time, Temperature, Voltage and VAR

- Control override based on Temperature and voltage

- Over/Under Voltage settings

- Perpetual calendar with time zones and day light savings Options for multiple seasons

- Close operations counters

Volt/VAR control

Voltage regulator controllers and Capacitor bank controllers can operate as part of an integrated Volt/VAR Control (IVVC) scheme or as a Centralized Volt/VAR control (CVVC) system. The IVVC or CVVC system works to achieve two key objectives:

Optimize Voltage - through ‘Conservation of Voltage’ that leads to reduced demand, that may result in decreased generation up to 6%.

Increased efficiency- through improved power factor and reduced VAR which helps to reduce power line losses.

Capacitor Bank Control

Robust Design

As a complete package, the Multilin Capacitor Bank Controller is offered in a NEMA-4 certified cabinet that is suitable for operation of harsh environments with an operating range of -40°C to + 60°C (-40°F to +140°F).

Mode of Operation

To provide optimal application flexibility, the Multilin Capacitor Bank Controller offers two modes or methods of operation in which the device can be implemented to control the Capacitor Bank:a) Manual Mode (Local Control or Remote Control). b) Automatic Mode

Manual Mode – Local Control

In this mode, it is possible to Open or Close the Capacitor Bank, locally, from the large pushbuttons located on the front panel of the Multilin Capacitor Bank Controller. For increased operational reliability and operator safety, inhibit functions configured in the unit will continue to operate as defined.

Manual Mode – Remote Control

In this mode, the commands for Open or Close of the Capacitor Bank are received via communication channels from the SCADA or an integrated Volt/VAR system. This communication channel can be provided via optional radio or cellular communications.

Automatic Mode

In automatic mode, the Multilin Capacitor Bank Controller issues commands to Open or Close the Capacitor Bank. In this mode, the Capacitor Bank is controlled

Key Capacitor Bank Control Features:

- Four Season Configuration

- Time Schedule Control

- Temperature control

- Voltage control

- VAR Control (Min Delta KVAR)

- Inhibit Controls

Key Features

- Star Neutral Overcurrent (Blown Fuse Indication)

- Customized automation schemes using FlexLogic™

- Expandable inputs and outputs for advanced applications

Protection

Reverse Power Detection

The Multilin Capacitor Bank Controller includes a Reverse Power Detection function, which defines the minimum pickup required to detect reverse power conditions.

Neutral Overcurrent Protection (Blown Fuse Condition)

In situations where the capacitor bank has been tripped due to a neutral current unbalance situation, the Multilin Capacitor Bank Controller will execute a reclose action to validate the state of the fault, ensuring the fault was not transient in nature. This automatic reclose action ensures maximizes system reliability.

Automation

The Multilin Capacitor Bank Controller offers powerful I/O and programmable FlexLogic™ options for advanced automation control, reducing the need for additional programmable controllers or discrete control relays. The Multilin Capacitor Bank Controller has three identical set point groups. The activation of the group can be done either from the HMI or via a Digital Input.

Set point group control

The Multilin Capacitor Bank Controller has three identical set point groups. The activation of the group can be done either from the HMI or via a Digital Input.

Virtual Inputs and Outputs

The Multilin Capacitor Bank Controller provides 32 virtual inputs and 32 virtual outputs that provide users the ability to send commands to the device. The Multilin Capacitor Bank Controller can accept commands from SCADA, through the front HMI, or front USB port to issue commands such as Open or Close.

Command Setting

The Multilin Capacitor Bank Controller has the ability to force commands from the menu structure accessible through the Multilin EnerVista setup software that runs on a PC.

FlexLogic™

Advanced FlexLogic in the Multilin Capacitor Bank Controller provides the ability to create customized control schemes. This minimizes the need for auxiliary components and wiring, thus reducing complexity and costs.

Key Features

- Metering - current, voltage, power, frequency, PF, Harmonics

- Event Recorder - Up to 256 time tagged events

- Temperature via RTD inputs

- Enhanced system diagnostics & reporting

Metering & monitoring

The Multilin Capacitor Bank Controller provides high accuracy metering and recording of AC signals, measuring the following key parameters:

- Phase-Ground Voltage (kV)

- Phase-to-Phase Voltage (kV)

- Line Voltage (kV)

- A, B, and C Phase Currents (A)

- Line Current (A)

- Ground Current (A)

- 3-Phase Active Power (kW)

- 3-Phase Reactive Power (kVAR)

- 3-Phase Apparent Power

- Delta Reactive Power (KVAR)

- Power Factor (Lag or Lead)

- 2nd to 8th harmonic up to 20% – for current

- 2nd to 8th harmonic up to 20% – for voltage

- THD in 20% – for current

- THD in 20% – for voltage

- Temperature [ ºC ]

These data points can be easily integrated into a customer’s database for seamless viewing through a SCADA or DMS system.

The Multilin Capacitor Bank Controller has the ability to monitor the following setpoints / conditions and issue an alarm if measured values fall outside of specified limits:

- Minimum voltage limit

- Bank switch failed

- Switching alarm (Reverse Power)

- Total close counter reached

- Max Daily operation counter reached

- Minimum VAR Delta (variation)

- Minimum Volt. Delta (variation)

- Neutral overcurrent

Event recorder

To significantly reduce time and enable more effective disturbance, post fault analysis and troubleshooting, the Multilin Capacitor Bank Controller provides an integrated event recorder and detailed diagnostic features.

Data Management and Diagnostics

The Multilin Capacitor Bank Controller provides advanced disturbance diagnostic features that significantly reduce the time and costs associated with troubleshooting power system events and reconstruction. Recording functions include enhanced diagnostics with a 10 channel RMS recorder Data Logger.

Statistics & Counters

The Multilin Capacitor Bank Controller provides counters which records key operational parameters to aid in enabling preventative maintenance programs. The Multilin Capacitor Bank Controller includes many counters & statistical values.

Advanced Device Health Diagnostics

Comprehensive device health diagnostic tests are performed by the Multilin Capacitor Bank Controller during startup and continuously at runtime to test its own major functions and critical hardware. These diagnostic tests monitor for conditions that could impact the Multilin Capacitor Bank Controller’s performance, evaluates the potential impact and criticality of this condition and presents the device status to operators, via SCADA and/or through the front panel display.

Communications

The Multilin Capacitor Bank Controller utilizes industry standard, communications technologies making it one of easiest and most flexible controllers to use and integrate into new and existing SCADA or DMS infrastructures. Supported communication protocols include:

- DNP 3.0

- Modbus RTU (RS485)

Multiple communication ports and protocols allow for remote control and easy access to device and system information. All communication ports are capable of simultaneous communications. The Multilin Capacitor Bank Controller can also communicate to Volt/VAR or SCADA systems via wireless communications media. The supported wireless media includes:

- Wireless Radio (MDS or customer specific)

- GSM/GPRS

- Pre-wired for future radio

Front Panel

Front Panel Quick Keys

Front Penel quick keys provides direct access to key individual setting parameters

Key Features

4-Level device security to maintain authorized access only

Simplified device configuration software tool and industry leading suite of software tools to manage and maintain Multilin devices.

Security

The Multilin Capacitor Bank Controller and associated software tools provide a suite of security features that ensure only approved personnel can make changes to the configuration of the system or execute commands. These functions enable a utility to meet NERC/CIP requirements.

Password Security

The Multilin Capacitor Bank Controller offers multiple levels of password security to limit access control based on settings or command levels. There are four levels of password security provided:

- Local Settings Access

- Local Control Access

- Remote Settings Access

- Remote Control Access

Local Access refers to users making changes using the front USB serial port and the HMI. Remote Access refers to users making changes using the rear RS485 port.

EnerVista™ Software

The EnerVista™ Suite is an industry-leading set of software programs that simplifies every aspect of using the Multilin Capacitor Bank Controller The EnerVista™ suite provides all the tools to monitor the status of the protected asset, maintain the controller, and integrate information measured by the DGCC into SCADA or the DMS monitoring systems. The ability to easily view sequence of events is an integral part of the setup software, as postmortem event analysis is critical to proper system operation.

Learn More

Recommended Products & services

DFP200 Digital Feeder Protection (Discontinued)

The DFP200 is a digital relay system that provides distribution feeder protection, control, metering, and monitoring. It uses waveform sampling of the current and voltage inputs at 32 times per cycle. Incorporating multiple functions in one package eliminates the need for expensive discrete components.

DFP200 Digital Feeder Protection (Discontinued)

The DFP200 is a digital relay system that provides distribution feeder protection, control, metering, and monitoring. It uses waveform sampling of the current and voltage inputs at 32 times per cycle. Incorporating multiple functions in one package eliminates the need for expensive discrete components.

Recommended Products & services

DFP100 Digital Feeder Relay (Discontinued)

The DFP100 is a digital protection, control, metering, and monitoring system. It uses waveform sampling of the current and voltage inputs together with appropriate algorithms to provide distribution feeder protection. The DFP100 incorporates the protection, control, metering, and both local and remote human interfaces in one assembly. This eliminates the need for expensive discrete components.

DFP100 Digital Feeder Relay (Discontinued)

The DFP100 is a digital protection, control, metering, and monitoring system. It uses waveform sampling of the current and voltage inputs together with appropriate algorithms to provide distribution feeder protection. The DFP100 incorporates the protection, control, metering, and both local and remote human interfaces in one assembly. This eliminates the need for expensive discrete components.

Recommended Products & services

DFF Digital Frequency Relay - Legacy

Manufacturing for this product has been discontinued. As an alternative, please refer to the F60, G60

DFF Digital Frequency Relay - Legacy

Manufacturing for this product has been discontinued. As an alternative, please refer to the F60, G60

Recommended Products & services

DDS Digital Distribution System - Legacy

Manufacturing for DDS has been discontinued. Please see individual product pages for more information.

The DDS family of devices provide economical protection, control, metering and monitoring functionality to electrical utilities and industrial customers.

DDS Digital Distribution System - Legacy

Manufacturing for DDS has been discontinued. Please see individual product pages for more information.

The DDS family of devices provide economical protection, control, metering and monitoring functionality to electrical utilities and industrial customers.

DDFR - Legacy

Distributed Digital Fault Recorder

Data Recording

Key Features

- Retrieves and Archives Transient Fault Records, Sequence of Event Records, and Disturbance Records recorded in protection relays distributed across the substation

- Automatically merges Events recorded in protection relays distributed across the network into a single substation wide Sequence of Event Record

- Stores months of fault and disturbance records internally, facilitating local substation analysis

- Discrete second Ethernet port will allow isolation between the network LAN and the IED’s connected to the DDFR.

Data Recording

The DDFR will detect that new information has been recorded in a relay and automatically retrieve and archive this data. Information that will be archived from protection relays include:

- Transient Fault Records

- Sequence of Event Records

- Disturbance Records

The DDFR is a Transient Fault, Sequence of Event, and Disturbance record archiving system that will seamlessly make available all of the recorded power system information necessary for performing post mortem fault and disturbance analysis.

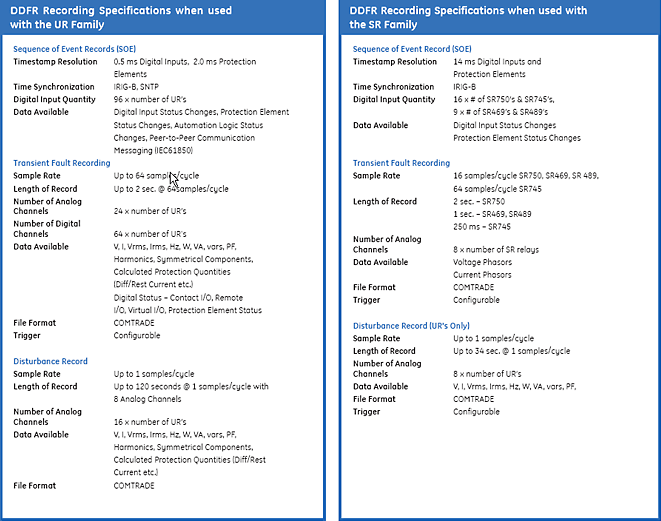

Sequence of Event Record (SOE)

The DDFR will retrieve the Event Records stored in protection relays distributed across a substation and merge all of these Events into a Station-Wide Sequence of Event Record. Connecting the protection relays to an IRIG-B time clock will synchronize the relay internal clocks with 1 millisecond accuracy and enable the DDFR to create a Station-Wide Event Record that will be an exact representation of the sequence of operations that occurred in the substation.

Sequence Of Event Records (SOE)

Sequence Of Event Records (SOE)

Transient Fault Records

Transient Fault Records (also known as Oscillography records) that are recorded in protection relays will be retrieve by the DDFR and stored in its internal memory space. All Transient Fault Records will be archived using a naming convention that will make it easy for users to relate the Transient Fault records with a particular substation fault. Each record will be stored with a name that includes the exact date and time that the record was initially triggered. If the Transient Fault record was originally recorded in the relay as a COMTRADE file, the DDFR will store this record in its native format; if the protection relay stores it’s record in another format, such as a CSV file, the DDFR will automatically convert this file into the COMTRADE-1999 format so that the record can be analyzed using a standard COMTRADE viewer.

Disturbance Records

Protections relays that are capable of recording Disturbance Records that are used for analyzing extended or evolving power system disturbances such as Voltage Sags or Swells will be retrieved and archived be the DDRF. All Disturbance Records will be archived using a naming convention that will make it easy for users to relate the Disturbance records with a particular power system disturbance. Each record will be stored with a name that includes the exact date and time that the record was initially triggered. Disturbance records will be stored in COMTRADE format and if needed, first convert this file to a COMTRADE file from its native format.

Key Features

- Effortlessly archives recorded data to a permanent enterprise network location or server for remote investigation and analysis

- Non-volatile, solid state storage able to store months worth of fault and disturbance information locally inside the DDFR.

Entreprise Network Archiving

The DDFR Archiving System will automatically copy all data stored in DDFR’s located throughout a companies wide area network into a centralized network location allowing users to analyze fault and disturbance data without having to be at the same location as the DDFR. This DDFR Archiving System that runs on coma network PC or Server can retrieve data from multiple DDFR’s thereby creating a permanent enterprise wide library of all past disturbances on your power system. The information collected by the DDFR Archiving System will be categorized in separate directories for each DDFR, making it easy for users to identify data about faults and disturbances related to each individual substation.

Archive data collected in DDFR’s distributed across the network into a centralized, accessible network location

Archive data collected in DDFR’s distributed across the network into a centralized, accessible network location

Viewing Archived Records

Users can analyze sequence of Event Records, Transient Fault Records, and Disturbance Records that have been stored on a DDFR or archived onto a network location by the DDFR Archiving System by using the EnerVista DDFR Setup Software. The DDFR Setup Software’s Event Record viewer and COMTRADE viewer can access archived records to provide local or remote analysis capability to anyone with access to network storage location.

Sequence of Event Viewer

The EnerVista™ DDFR Setup Software contains a Sequence of Event viewer that allows for easy analysis of the Events stored in the DDFR or archived to the network location. Each recorded event will contain detailed information including:

- Timestamp of Event

- Description of the Event

- Name of Substation

- Name of Source Relay

- Model of the Source Relay

The Sequence of Event viewer provides the ability to sort the recorded events by any of the available fields of information or to perform queries to show only the events that are necessary for troubleshooting a particular fault.

COMTRADE Viewer

The COMTRADE viewer that is included with the EnerVista DDFR Setup Software provides the ability of analyzing the Transient Fault Records and Disturbance Records that have been archived by the DDFR. This full featured COMTRADE viewer allows for analyzing records in a standard time based format that shows the magnitude of all measured quantities, or in Phasor diagram view that shows the magnitude and angle differences between any of the parameters. The COMTRADE viewer can also perform a harmonic analysis on all measured Phasor quantities and display the harmonic content for every point in the record up to the 25th harmonic.

Meet Standards DDFR Requirements

When used with advanced microprocessor based relays such as the UR family, the DDFR System meets or exceeds requirements of International Standards for Digital Fault Recording.

Recommended Products & services

DBF Digital Breaker Failure - Legacy

Manufacturing for this product has been discontinued. As an alternative, please refer to the 8 Series and UR Family relays

DBF Digital Breaker Failure - Legacy

Manufacturing for this product has been discontinued. As an alternative, please refer to the 8 Series and UR Family relays

Recommended Products & services

DAR Modular Reclosing Relays (Discontinued)

The relays type DAR 2000 are multiple reclose electronic relays, manufactured in modular version, designed to perform automatically the three-phase reclose of a power breaker, tripped by the action of a protection relay.

DAR Modular Reclosing Relays (Discontinued)

The relays type DAR 2000 are multiple reclose electronic relays, manufactured in modular version, designed to perform automatically the three-phase reclose of a power breaker, tripped by the action of a protection relay.