Multilin F650

Cost effective protection, automation and control of distribution feeders

The Multilin F650 has been designed for the protection, control and automation of feeders or related applications. The Multilin F650 feeder protection relay provides high speed protection and control for feeder management and bay control applications, and comes with a large LCD and single line diagrams that can be built for bay monitoring and control for various feeder arrangements including ring-bus, double breaker or for breaker and half.

Key Benefits

- Comprehensive and flexible protection and control device for feeder applications

- Increased system uptime and improved stability with load shedding and transfer schemes

- Advanced automation capabilities for customized protection and control solutions

- Human machine interface (HMI) with graphical LCD, programmable buttons, and easy keys for selecting setting menus, and submenus

- Reduced replacement time with modular draw-out construction

- Reduced troubleshooting time and maintenance costs with IEEE 1588 (PTP), IRIG-B and SNTP time synchronization (configuration of two different SNTP masters), event reports, waveform capture, and data logger

- Simplified system integration with communications supporting serial and Ethernet interfaces as well as multiple protocols

- Embedded IEC® 61850 protocol (and support for edition 2), IEC 60870-5-103/104, IEC 62439/PRP/HSR, IEEE 802.1D/RSTP

- Proven interoperability and KEMA 61850 Edition 2 certified

Applications

- Primary or back-up protection and control for feeders on solidly grounded, high impedance grounded or resonant grounded systems

- Bus blocking/Interlocking schemes

- High-speed fault detection for arc flash

- Throw over schemes (bus transfer scheme applications)

- Load shedding schemes based on voltage and frequency elements

- Distributed Generation (DG) interconnect protection, including active and passive anti-islanding

Multilin F650

Cost effective protection, automation and control of distribution feeders

The Multilin F650 has been designed for the protection, control and automation of feeders or related applications. The Multilin F650 feeder protection relay provides high speed protection and control for feeder management and bay control applications, and comes with a large LCD and single line diagrams that can be built for bay monitoring and control for various feeder arrangements including ring-bus, double breaker or for breaker and half.

Key Benefits

- Comprehensive and flexible protection and control device for feeder applications

- Increased system uptime and improved stability with load shedding and transfer schemes

- Advanced automation capabilities for customized protection and control solutions

- Human machine interface (HMI) with graphical LCD, programmable buttons, and easy keys for selecting setting menus, and submenus

- Reduced replacement time with modular draw-out construction

- Reduced troubleshooting time and maintenance costs with IEEE 1588 (PTP), IRIG-B and SNTP time synchronization (configuration of two different SNTP masters), event reports, waveform capture, and data logger

- Simplified system integration with communications supporting serial and Ethernet interfaces as well as multiple protocols

- Embedded IEC® 61850 protocol (and support for edition 2), IEC 60870-5-103/104, IEC 62439/PRP/HSR, IEEE 802.1D/RSTP

- Proven interoperability and KEMA 61850 Edition 2 certified

Applications

- Primary or back-up protection and control for feeders on solidly grounded, high impedance grounded or resonant grounded systems

- Bus blocking/Interlocking schemes

- High-speed fault detection for arc flash

- Throw over schemes (bus transfer scheme applications)

- Load shedding schemes based on voltage and frequency elements

- Distributed Generation (DG) interconnect protection, including active and passive anti-islanding

Key Features

- Time, instantaneous & directional phase, neutral, ground and sensitive ground overcurrent

- Manual close with cold load pickup control, Forward Power and Directional Power Units

- Load encroachment supervision

- Wattmetric ground fault detection

- Positive and negative sequence based over/under voltage elements

- 2nd Harmonic restraint

- CT Supervision

- Four-shot autorecloser with synchronism check

- Trip circuit supervision, breaker control and

breaker failure - Frequency protection (rate of change and six

stages of under and over frequency) - Broken conductor and locked rotor

- Programmable digital inputs and outputs

- 6 Setting Groups

Protection & Control

The F650 feeder protection relay provides high speed protection and control for feeder management and bay control applications, including:

| 25 | Synchrocheck |

| 27/27X | Bus/Line Undervoltage |

| 32 | Sensitive Directional Power |

| 32FP | Forward Power |

| 32N | Wattmetric zero-sequence directional |

| 46 | Negative Sequence Time Overcurrent |

| 47 | Negative Sequence Voltage |

| 48 | Blocked Rotor |

| 49 | Thermal Image - overload protection |

| 50 BF | Breaker Failure |

| 50PH/PL | Phase Instantaneous Overcurrent (High/Low) |

| 50N | Neutral Instantaneous Overcurrent |

| 50G | Ground Instantaneous Overcurrent |

| 50SG | Sensitive Ground Instantaneous Overcurrent |

| 50IG | Isolated Ground Instantaneous Overcurrent |

| 51N | Neutral Time Overcurrent |

| 51G | Ground Time Overcurrent |

| 51SG | Sensitive Ground Time Overcurrent |

| 51PH/V | Voltage Restraint Phase Time Overcurrent |

| 51PL/V | |

| 59/59X | Bus/Line Overvoltage |

| 59NH/NL | Neutral Overvoltage - High/Low |

| 67P | Phase Directional Overcurrent |

| 67N | Neutral Directional Overcurrent |

| 67G | Ground Directional Overcurrent |

| 67SG | Sensitive Ground Directional Overcurrent |

| 79 | Autorecloser |

| 81 U/O | Under/Over Frequency Broken Conductor Detection |

| 81R | Frequency Rate of Change |

| VTFF | VT Fuse Failure Detection |

| Load Encroachment |

Key Features

- Fault locator, fault and event recorder

- Comprehensive breaker monitoring

- High resolution oscillography and Data Logger, with programmable sampling rate

- Metering: V, I, Hz, W, VA, PF

- Demand: Ia, Ib, Ic, Ig, Isg, I2, MW, MVA

- Breaker Arcing Current (I2t)

- Fault Locator

Monitoring & Metering

The F650 provides advanced monitoring and metering that includes:

Current Transformer Failure

In event of abnormal behaviour of the CT or a loss of phase the F650 detects a change in zero sequence current to initiate a CT failure event and an output that can be used to block critical protection functions. This feature can be inhibited either by zero sequence voltage, ground /sensitive ground current.

2nd harmonic inhibit

The F650 provides 2nd harmonic detection that can be used to block sensitive elements, especially during transformer energization. The setting can be based on any phase, any two phases, all three phases or an average of the 3 phases.

VT Fuse Failure

Use the VT Fuse Failure feature to issue an alarm and/or to block voltage driven protection functions that can operate incorrectly due to an abrupt partial or total voltage loss. This loss is caused by the voltage transformers secondary circuit protection fuse failure. Different methods are used to detect the different types of VT fuse failure.

Trip Circuit Monitoring

F650 can be used to monitor the integrity of both the breaker trip and closing coils and circuits. The supervision inputs monitor both the battery voltage level, while the outputs monitor the continuity of the trip and/or closing circuits, by applying a small current through the circuits.

Basic Metering

Ia, Ib, Ic, Ig, Isg, Va, Vb, Vc and Vx signals are available locally and remotely and can be stored in the oscillography record or data logger.

Event Recording and Oscillography

The F650 is capable of storing 479 or 512 (depending on the selected model) time-tagged events (1 ms tagging), to help with troubleshooting. The trigger point, the channels, and sampling rate of the oscillography files are user programmable features. Up to five seconds at maximum sample rate can be stored.

Advanced Communications

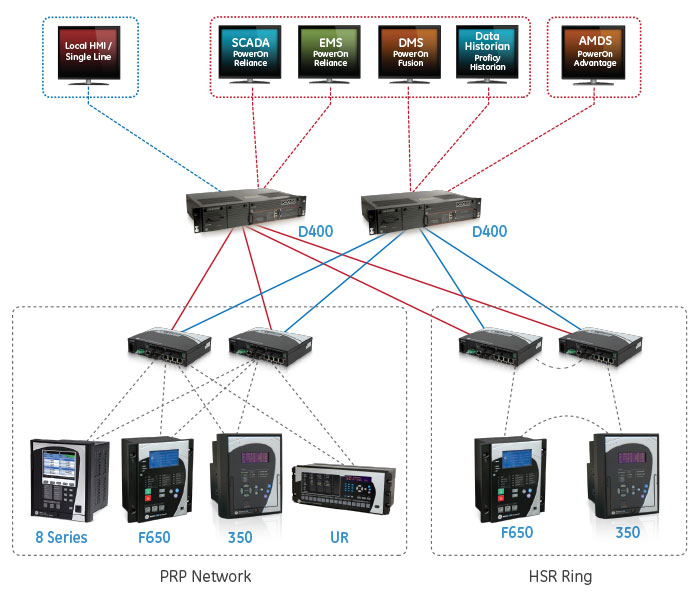

The F650 incorporates the industry-leading communication technologies making it one of the easiest and flexible feeder protection relays for use and integration into new and existing infrastructures. The F650 provides optional Parallel Redundancy Protocol (PRP), High Availability Seamless Ring (HSR) (IEC 62439-3) and also Rapid Spanning Tree Protocol (RSTP) (IEEE 802.1D) to increase network availability and reliability for critical applications.

The F650 includes up to three communication ports that operate simultaneously. Redundant ports are also available for special applications.

The F650 supports popular industry leading standard protocols enabling easy, direct integration into electrical SCADA and HMI systems. The protocols supported by the F650 include:

- IEC 61850 Edition 2

- DNP 3.0

- Modbus RTU

- Modbus TCP/IP

- IEC 60870-5-103 and IEC 60870-5-104

- PRP & HSR (IEC 62439-3)

- RSTP (IEEE 802.1D)

- IEEE 1588 (PTP) for time synchronization

The F650 provides integration with 61850 standard edition 2. IEC 61850 allows for the seamless connection of IEDs from multiple vendors. In addition to device interoperability, these protocols are designed to control the substation via a LAN instead of through discrete wiring to an RTU.

Example of redundant HSR and PRP Architecture

Redundancy protocols (PRP and HSR) can be used for various networking architectures including combined PRP/HSR topologies.

EnerVista Software

The EnerVista Suite is an industry-leading set of software programs that simplifies every aspect of using the F65 relay. The EnerVista suite provides all the tools to monitor the status of your the protected asset, maintain the relay, and integrate information measured by the F650 into DCS or SCADA monitoring systems. Convenient COMTRADE and Sequence of Events viewers are an integral part of the 650 Setup software included with every F650 relay, to carry out postmortem event analysis to ensure proper protection system operation.

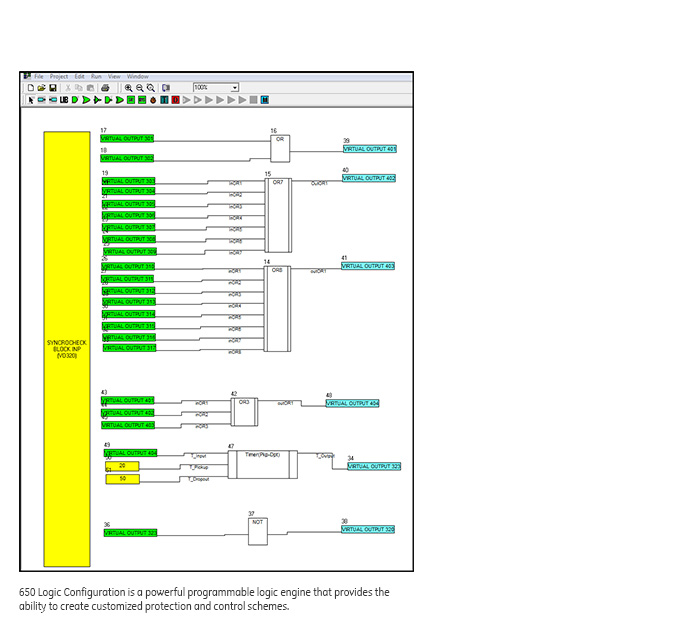

The 650 Logic Configuration software is a powerful programming logic engine that provides the ability to create customized protection and control schemes thereby minimizing the need, and costs associated with auxiliary components and wiring.