Oil Test and Analysis

The analysis of dielectric materials and the preventive maintenance programs of oil-insulated equipment can reduce the risk of unscheduled outages, ensuring asset performance and durability. Transformer active part and cellulosic insulation immersed in oil generate markers during their lifecycle. With analysis, oil variations can be detected at an early stage before failure occurs. Oil analysis provides critical information on asset health status, including electrical properties and ageing.

Oil analysis can be provided on all brands of high and medium voltage (HV/MV) transformers including OLTC, instrument, and on-board transformers.

GE Vernova provides oil tests and analysis performed in GE Vernova’s labs, along with a detailed report that includes remedial actions and condition severity as per IEEE® or IEC® standards.

Analysis

GE Vernova performs reliable preventive and curative fluid analysis to provide an expert assessment of overall transformer condition:

- Thermal and electrical faults are detected by measuring the concentration, respective proportions and rate of 13 characteristic gases.

- Dielectric fluid condition is determined through dielectric strength, water content and the acidity index, verifying insulating and cooling properties.

- Pollution level is evaluated by detecting PCBs in mineral oils and checking compliance with environmental regulations.

- Cellulose insulation is assessed through furans analysis as well as new investigation methods using methanol/ethanol tests.

Other assessments can also be performed on a case-by-case basis depending on various criteria including the device’s age, brand, power, load, and criticality.

GE Vernova Advantage

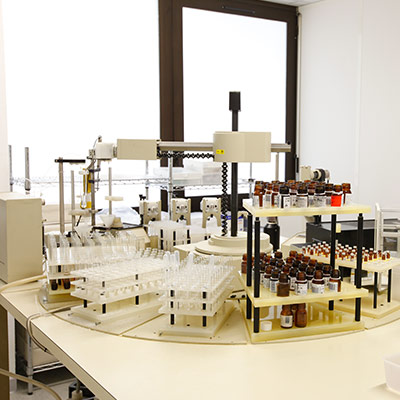

For 30 years, GE Vernova oil analysis and transformer specialists have performed highly accurate tests in accredited oil labs which have pioneered DGA, furans and methanol analysis.

The analysis report provides clear diagnosis and operational recommendations summarized in a simple colored-coded severity index.

It can be accessed online or during an annual customer review. Analysis data and report can be integrated in GE Vernova Asset Performance Management platform.

Our teams can respond to emergency situations, even during peak volume times.

Based on transformer criticality and condition, GE Vernova can provide flexible services agreements to monitor data and alarms from DGA continuous online monitoring systems.

Customers and channel partners can select from packaged solutions and book an order in the GE Vernova’s Grid Solutions Online Store.

Oil Test and Analysis

The analysis of dielectric materials and the preventive maintenance programs of oil-insulated equipment can reduce the risk of unscheduled outages, ensuring asset performance and durability. Transformer active part and cellulosic insulation immersed in oil generate markers during their lifecycle. With analysis, oil variations can be detected at an early stage before failure occurs. Oil analysis provides critical information on asset health status, including electrical properties and ageing.

Oil analysis can be provided on all brands of high and medium voltage (HV/MV) transformers including OLTC, instrument, and on-board transformers.

GE Vernova provides oil tests and analysis performed in GE Vernova’s labs, along with a detailed report that includes remedial actions and condition severity as per IEEE® or IEC® standards.

Analysis

GE Vernova performs reliable preventive and curative fluid analysis to provide an expert assessment of overall transformer condition:

- Thermal and electrical faults are detected by measuring the concentration, respective proportions and rate of 13 characteristic gases.

- Dielectric fluid condition is determined through dielectric strength, water content and the acidity index, verifying insulating and cooling properties.

- Pollution level is evaluated by detecting PCBs in mineral oils and checking compliance with environmental regulations.

- Cellulose insulation is assessed through furans analysis as well as new investigation methods using methanol/ethanol tests.

Other assessments can also be performed on a case-by-case basis depending on various criteria including the device’s age, brand, power, load, and criticality.

GE Vernova Advantage

For 30 years, GE Vernova oil analysis and transformer specialists have performed highly accurate tests in accredited oil labs which have pioneered DGA, furans and methanol analysis.

The analysis report provides clear diagnosis and operational recommendations summarized in a simple colored-coded severity index.

It can be accessed online or during an annual customer review. Analysis data and report can be integrated in GE Vernova Asset Performance Management platform.

Our teams can respond to emergency situations, even during peak volume times.

Based on transformer criticality and condition, GE Vernova can provide flexible services agreements to monitor data and alarms from DGA continuous online monitoring systems.

Customers and channel partners can select from packaged solutions and book an order in the GE Vernova’s Grid Solutions Online Store.

France – Laboratory of Oil Services

Parc technologique du canal

8 rue Giotto

31520 Ramonville-St-Agne

Phone: +33 (0)562 190 560

Email: [email protected]

Web: LOS

Certified ISO 9001, ISO 14001, OHSAS 18001, Accredited COFRAC based on ISO 17025

Australia - Transformer Oil Testing Laboratory

Unit4B/29-41 Lysaght Street Acacia Ridge,

QLD 4110

Australia

Phone: +61 408 885 801

Email: Email Contact

Certified ISO 9001, ISO 14001, OHSAS 18001, Accredited National Association of Testing Authorities (NATA)

Turkey - Transformer Oil Testing Laboratory

Baris Mah. Guney Yanyol Cad. No:320 Gebze

41410 Kocaeli

Turkey

Phone: +90 (0) 262 648 3300 Ext 3373-3390

Email: Email Contact 1 and Email Contact 2

Certified ISO 9001, ISO 14001, OHSAS 18001, Accredited Turkish Accreditation Agency TS EN ISO/IEC 17025