Multilin 889

Comprehensive Protection and Management

The Multilin 889 relay, a member of the Multilin 8 Series protective relay platform, has been designed for the protection, control, monitoring and management generators and in-zone transformers used in both industrial and utilities applications.

The Multilin 889 provides advanced, high-speed protection, extensively customizable programmable logic, and flexible configuration capabilities, to maximize the operational performance and life of critical generators.

Equipped with the latest in advanced communications, the Multilin 8 Series supports IEC 61850 Edition 2 ensuring simplified device integration and dual communication ports with IEC 62439/PRP, enabling users to achieve zero latency in communications for high reliability network architectures, ensuring complete asset monitoring and control.

Key Benefits

- Enhanced generator protection algorithms provide sub-cycle differential protection, ensuring faster fault clearing times for reduced generator damage

- Dedicated generator monitoring and control functions providing mission critical operational data to enable a pro-active maintenance approach

- Additional overall generator-transformer differential (87O) providing additional back-up protection

- Advanced differential protection for both generator and in-zone transformer

- Industry standard cyber security tools such as AAA, Radius, RBAC and Syslog enabling NERC/CIP requirements

- Draw-out design simplifies testing and increases process uptime

- Optional Wi-Fi minimizes system configuration and facilitates safe relay programming and diagnostic retrieval

To simplify the migration and upgrade from an existing SR 489 protection relays, retrofit kits have been developed which significantly simplify the upgrade process.

Multilin 889

Comprehensive Protection and Management

The Multilin 889 relay, a member of the Multilin 8 Series protective relay platform, has been designed for the protection, control, monitoring and management generators and in-zone transformers used in both industrial and utilities applications.

The Multilin 889 provides advanced, high-speed protection, extensively customizable programmable logic, and flexible configuration capabilities, to maximize the operational performance and life of critical generators.

Equipped with the latest in advanced communications, the Multilin 8 Series supports IEC 61850 Edition 2 ensuring simplified device integration and dual communication ports with IEC 62439/PRP, enabling users to achieve zero latency in communications for high reliability network architectures, ensuring complete asset monitoring and control.

Key Benefits

- Enhanced generator protection algorithms provide sub-cycle differential protection, ensuring faster fault clearing times for reduced generator damage

- Dedicated generator monitoring and control functions providing mission critical operational data to enable a pro-active maintenance approach

- Additional overall generator-transformer differential (87O) providing additional back-up protection

- Advanced differential protection for both generator and in-zone transformer

- Industry standard cyber security tools such as AAA, Radius, RBAC and Syslog enabling NERC/CIP requirements

- Draw-out design simplifies testing and increases process uptime

- Optional Wi-Fi minimizes system configuration and facilitates safe relay programming and diagnostic retrieval

To simplify the migration and upgrade from an existing SR 489 protection relays, retrofit kits have been developed which significantly simplify the upgrade process.

Full Color Graphical HMI Front Display

A large, full color Graphic Control Panel (GCP) ensures clear representation of critical status and measurements. The 8 Series offers two options for front panels:

- 10 Programmable Push buttons with 12 programmable LEDs

- 3 Programmable Push buttons and 12 programmable LEDs

Switchgear Control and Configurable SLD

The Multilin 8 Series provides a configurable dynamic SLD up to six (6) pages for comprehensive switchgear control of up to 3 breakers and 9 disconnect switches; including interlocks. Up to 15 digital and metering status elements can be configured per SLD page.

Platform Overview

The Multilin 8 Series platform delivers the highest level of quality, reliability and performance with…

Innovative Technology & Design

- Patented environmental monitoring and diagnostics helps visibility on change in environmental parameters

- Advanced, flexible and embedded communications: IEC® 61850 Ed2, IEC 62439/PRP, Modbus® RTU & TCP/IP, DNP3.0, IEC 60870-5-104, IEC 60870-5-103

- Single setup and configuration across the platform

- Field swappable power supply

- Draw-out design simplifies testing, commissioning and maintenance, thereby increasing process uptime

- Optional Wi-Fi connectivity minimizes system configuration and provides safe relay programming and diagnostic retrieval

- Elimination of electrolytic capacitors

Exceptional Quality & Reliability

- IPC A-610-E Class 3 Manufacturing standards – highest industry standards for electronic manufacturing

- Highest reliability standards for electronics testing

- Environmental Stress Screening and full functional testing

- Rated for IP54 applications

- Standard Harsh Conformal Coating

Uncompromising Service & Support

- Covered under GE Vernova’s 10 year warranty plan

- Fully designed, tested and assembled at GE Vernova facilities

Multilin 889 Overview

The 889 has been designed for the protection, control, and management of generators and associated unit transformers in critical utility and industrial applications.

Applications:

- Comprehensive protection from small to large generators

- Industrial or utility power generation

- Co-generation and renewable generation applications

- Unit Transformer Protection applications

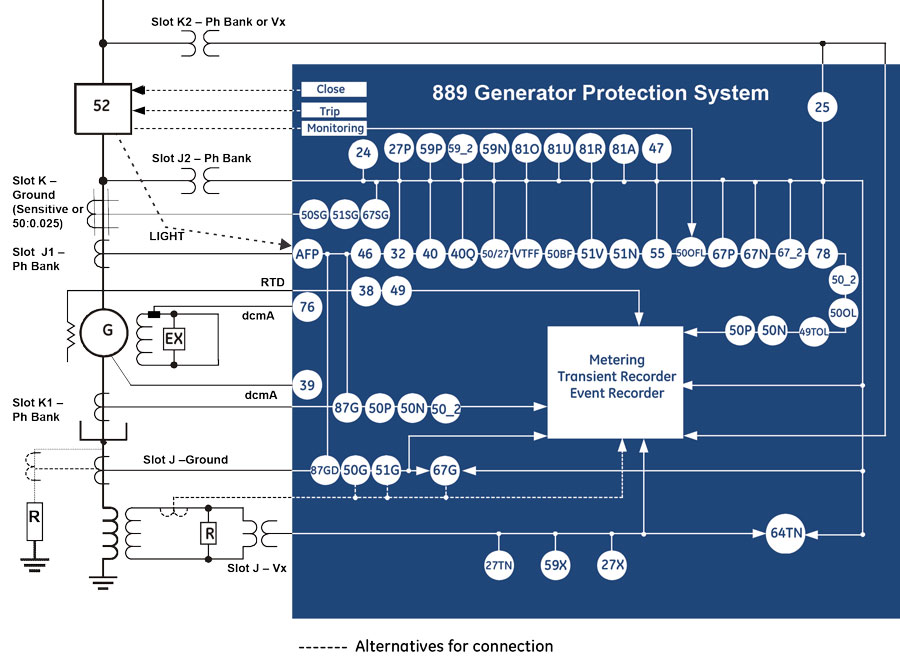

Multilin 889 feeder protection relay functional block diagram

ANSI Device Numbers & Functions

| Device Number | Function |

|---|---|

| 24 | Volts per Hertz |

| 25 | Synchrocheck |

| 27P | Phase Undervoltage |

| 27X | Auxiliary Undervoltage |

| 27TN | Third Harmonic Neutral Undervoltage |

| 32 | Directional Power |

| 38 | Bearing Overtemperature (RTD) |

| 39 | Bearing Vibration (dcmA) |

| 40 | Loss of Excitation |

| 40Q | Reactive Power |

| 46 | Generator Unbalance |

| 47 | Phase Reversal |

| 49 | Thermal (RTD) |

| 49TOL | Thermal Overload |

| 50/27 | Inadvertent Energization |

| 50BF | Breaker Failure |

| 50G | Ground Instantaneous Overcurrent |

| 50SG | Sensitive Ground Instantaneous Overcurrent |

| Device Number | Function |

|---|---|

| 50N | Neutral Instantaneous Overcurrent |

| 50P | Phase Instantaneous Overcurrent |

| 50_2 | Negative Sequence Instantaneous Overcurrent |

| 50OFL | Offline Overcurrent |

| 50OL | Overload |

| 51G | Ground Time Overcurrent |

| 51N | Neutral Time Overcurrent |

| 51SG | Sensitive Ground Time Overcurrent |

| 51V | Voltage Restrained Time Overcurrent |

| 55 | Power Factor |

| 59N | Neutral Overvoltage |

| 59P | Phase Overvoltage |

| 59X | Auxiliary Overvoltage |

| 59_2 | Negative Sequence Overvoltage |

| 64TN | 100% Stator Ground using 3rd Harmonic Voltage Differential |

| 67G | Ground Directional Overcurrent |

| Device Number | Function |

|---|---|

| 67N | Neutral Directional Overcurrent |

| 67P | Phase Directional Overcurrent |

| 67SG | Sensitive Ground Directional Overcurrent |

| 67_2 | Negative Sequence Directional Element |

| 76 | Excitation Current Protection (dcmA) |

| 78 | Out-of-Step Protection |

| 81A | Frequency out-of-band |

| 81O | Overfrequency |

| 81U | Underfrequency |

| 81R | Frequency Rate of Change |

| 87G | Generator Stator Differential |

| 87O | Overall Unit (Gen-Xfrm) Protection |

| 87GD | Restricted Ground Fault |

| AFP | Arc Flash Protection |

| VTFF | VT Fuse Failure |

Generator Stator Differential Protection

The 889 utilizes high-speed dual slope differential protection for detecting and clearing of stator phase faults. Advanced CT saturation detection algorithms maintain immunity to saturation conditions that may be caused due to external disturbances through the use of a directional check that provides additional supervision and ensures the fault is internal to the generator before triggering it to trip.

Overall Generator & Transformer Differential Protection

The 889 can provide overall generator and transformer differential protection (87O). It covers the protection zones from the generator neutral to the GSU (Generator Step-Up) transformer’s High Voltage (HV) winding. This additional protection element provides backup to both Generator Stator Differential (87G) and a dedicated transformer differential in a transformer relay (i.e.: Multilin 845 Transformer Protection System). The 889 with this Generator-Transformer Differential protection supports transformer setup, provides enhanced protection security by including both restrained and unrestrained (instantaneous) differential protection.

100% Stator Ground

100% stator ground fault protection is provided through an overvoltage element and an adaptive voltage differential feature responding to the unbalance of the third harmonic at the machine terminals and at the neutral point. The 889 compares the machine neutral voltage and ground current to determine if ground directional faults are within or outside the generator.

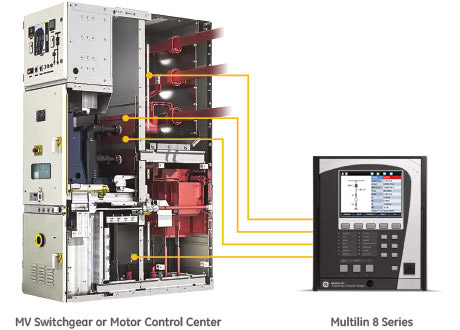

Integrated Arc Flash Protection

The Multilin 8 Series supports an integrated arc flash module providing constant monitoring of an arc flash condition within the switchgear, motor control control centers, or panelboards. With a 2ms protection pass, the 8 Series is able to detect light and overcurrent using 4 arc sensors connected to the 8 Series relay. In situations where an arc flash/fault does occur, the relay is able to quickly identify the fault and issue a trip command to the associated breaker thereby reducing the total incident energy and minimizing resulting equipment damage.

Self-monitoring and diagnostics of the sensors ensures the health of the sensors as well as the full length fiber cables. LEDs on the front panel display of the 889 can be configured to indicate the health of the sensors and its connections to the relay.

Fast, reliable arc flash protection with light-based arc flash sensors integrated within the Multilin 8 Series of protection & control devices. With arc flash detection in as fast as 2msec, the costs associated with equipment damage and unplanned down

Fast, reliable arc flash protection with light-based arc flash sensors integrated within the Multilin 8 Series of protection & control devices. With arc flash detection in as fast as 2msec, the costs associated with equipment damage and unplanned down

Monitoring & Diagnostics

The Multilin 889 includes high accuracy metering and recording for all AC signals. Voltage, current, and power metering are built into the relay as a standard feature. Current and voltage parameters are available as total RMS magnitude, and as fundamental frequency magnitude and angle.

Data Logging

The Multilin 889 includes high accuracy metering and recording for all AC signals. Voltage, current, and power metering are built into the relay as a standard feature. Current and voltage parameters are available as total RMS magnitude, and as fundamental frequency magnitude and angle.

Log generator operating parameters to allow for analyzing generator loading and performance over weeks and months.

Dedicated Generator System Monitoring & Control

- Running Hours - The 889 can calculate/accumulate generator running hours, which may be of interest for periodic maintenance. if total running hours exceed the use-setting limit, the function would alarm the condition.

- Frequency OOB Accumulation - The Frequency Out-Of-Band (OOB) Accumulation feature provides diagnostic information and alarms based on the accumulated off-nominal (out-of-band) frequency operation time of a turbine over several frequency bands. This alarm can be used to schedule maintenance or other actions as desired

Advanced Generator Monitoring Diagnosis

The 889 can calculate/accumulate generator running hours, which may be of interest for periodic maintenance. if total running hours exceed the use-setting limit, the function would alarm the condition.

- Bearing vibration (Analog Input)

- Excitation current (Analog Input)

- Any generator transducer (dcmA) input monitoring

- Breaker Health

- Data logger, Oscillography, Event Recorder.

The Multilin 889 offers a comprehensive generator health report that provides an easy-to-read snapshot of a generator's health and operating condition. Based on graphical representation and trend values of the generator historical data, the 889 enables operators and asset managers to identify process issues and maintenance requirements before damage occurs and costly repairs are required.

Trip and Close Circuit Monitoring

The 889 relay provides Trip and Close Circuit Monitoring elements

Breaker Arcing Current

This element calculates an estimate of the per-phase wear on the breaker contacts by measuring and integrating the current squared passing through the breaker contacts as an arc. When the threshold is exceeded in any phase, the relay can set an output operand and set an alarm.

Breaker Health

The 889 relay provides breaker health information by monitoring and analyzing the operation count, arcing energy of breaking current, arcing time, tripping time, closing time and spring charging time if applicable

Environmental Monitoring

The 889 implements a patented environmental monitoring system that measures and provides operating condition information. Reliable and secure operation of the 889 relay and other electronic devices in the vicinity may be affected by environmental factors. The 869 relay has been designed to meet or exceed all required industry standards. Some operating conditions may be beyond those standards and reduce total lifespan of the device.

The 8 Series built-in environmental awareness feature (patent “Systems and methods for predicting maintenance of intelligent electronic devices”) collects the histograms of each operating condition from the point the device is put into service. Monitored environmental conditions include temperature, humidity and transient voltage. These parameters are now available as Flexelement to output alarms in case of limits reached due to Temperature, humidity or surges. (Please confirm if this is the part to replace the existing part).

The 889 implements a patented environmental monitoring system that measures and provides operating condition information. Reliable and secure operation of the 889 relay and other electronic devices in the vicinity may be affected by environmental factors. The 869 relay has been designed to meet or exceed all required industry standards. Some operating conditions may be beyond those standards and reduce total lifespan of the device.

Communications

The 889 provides advanced communications technologies for remote data and engineering access, making it easy and flexible to use and integrate into new and existing infrastructures. Direct support for fiber optic Ethernet provides high-bandwidth communications, allowing for low-latency controls and high-speed file transfers of relay fault and event record information. The 889 also supports two independent IP addresses, providing high flexibility for the most challenging of communication networks.

Providing several Ethernet and serial port options, dual independent Ethernet Ports, and support for a wide range of industry standard protocols, the 889 enables easy, direct integration into DCS and SCADA systems. The 889 supports the following protocols:

- IEC 61850 Ed2, IEC 62439 / PRP

- DNP 3.0, IEC 60870-5-103, IEC 60870-5-104

- Modbus RTU, Modbus TCP/IP

The 889 has two interfaces as USB front port and Wi-Fi for ease of access to the relay. Wi-Fi Connectivity:

- Simplify set-up and configuration

- Simplify diagnostic retrieval

- Eliminate personnel in front of switchgear

- WPA-2 security

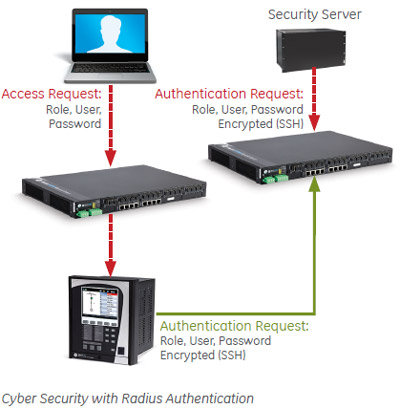

Cyber Security

The 869 cyber security enables the device to deliver full cyber security features that help operators to comply with NERC CIP guidelines and regulations.

AAA Server Support (Radius/LDAP)

Enables integration with centrally managed authentication and accounting of all user activities and uses modern industry best practices and standards that meet and exceed NERC CIP requirements for authentication and password management.

Role Based Access Control (RBAC)

Efficiently administrate users and roles within UR devices. The new and advanced access functions allow users to configure up to five roles for up to eight configurable users with independent passwords. The standard “Remote Authentication Dial In User Service” (Radius) is used for authentication.

Event Recorder (Syslog for SEM)

Capture all cyber security related events within a SOE element (login, logout, invalid password attempts, remote/local access, user in session, settings change, FW update, etc), and then serve and classify data by security level using standard Syslog data format. This will enable integration with established SEM (Security Event Management) systems.

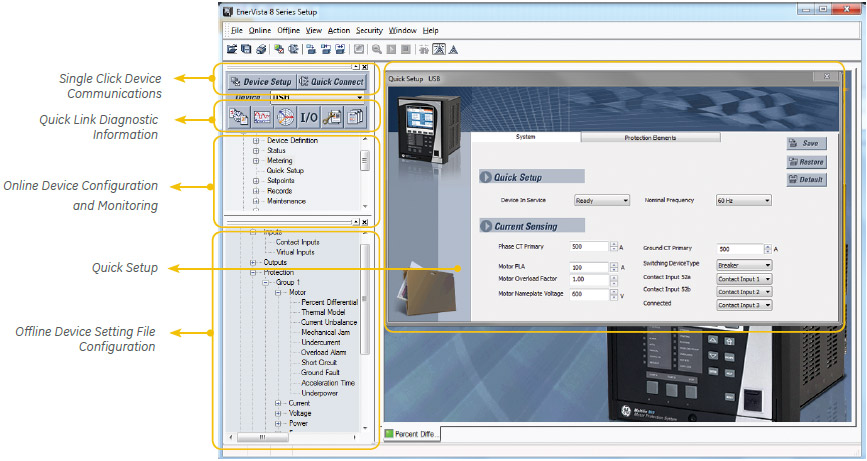

Software & Configuration

The EnerVista™ suite is an industry-leading set of software programs that simplifies every aspect of using the Multilin 869.

EnerVista provides all the tools to monitor the status of the protected asset, maintain the device and integrate the information measured by the Multilin 8 Series, into SCADA or DCS process control systems. The ability to easily view sequence of events is an integral part of the setup software, as postmortem event analysis is critical to proper system management.

EnerVista Launchpad

The setup tools within Launchpad allow for the configuration of devices in real-time, by communicating via serial, Ethernet or modem connections, or offline by creating device setting files to be sent to devices at a later time.

8 Series Setup Software

8 Series Setup Software is single setup and configuration tool across the platform and can reduce device setup and configuration time.

Simplified Setup & On-Going Maintenance

8 Series Retrofit Kit

Retrofit Existing SR 489 Devices to the Multilin 889 in Minutes

Traditionally, retrofitting an existing relay has been a challenging, time consuming task often requiring re-engineering, new drawings, panel modifications, re-wiring and re-testing.

The 8 Series Retrofit Kit provides a quick, 3-step solution to upgrade previously installed SR 489 relays. With the new 8 Series Retrofit Kit users are able to install the 889 Generator Management System without modifying existing cutouts and wiring, and without any drawing changes or re-engineering time.

EnerVista 8 Series Setup Software provides automated setting file conversion. Once completed, a graphical report is provided to verify and call out any specific settings that may need attention.

Simply remove the upper, lower and low voltage terminal blocks and then remove the SR chassis from the panel. No need to disconnect any of the field wiring.

Insert the new 8 Series Retrofit chassis into the switchgear and simply plug-in the old terminal blocks - there is no need to make any cut-out modifications or push and pull cables.