Engineering Services

Our engineering services team provides a wide range of capabilities to assist you with your power protection, substation automation, and monitoring and diagnostics challenges.

We provide end-to-end solutions to support your project needs. From new installations to understanding the best way to upgrade an existing system, our engineering team has been trusted to analyze, design, and implement modern power systems with a broad range of engineering services that includes:

- Assuring proper logic design and IED configuration based on your specific project needs through our support on complex configurations like busbar engineering and automatic transfer schemes.

- Communication mapping on IEC 61850 MMS GOOSE, Modbus, Ethernet Global Data (EGD) or other protocols for smooth system integration.

- Uploading of configuration files prior to delivery to reduce work at destination through pre-load configuration.

- Confirming alignment between your project-specific requirements and protection system performance with our test procedures and factory acceptance testing (FAT).

Our range of Engineering services includes but is not limited to:

- Busbar engineering solutions

- Digital substation standardization

- IED configuration

- Protection schemes

- Automatic transfer schemes

- DER integration studies, dynamic line rating (DLR), distribution automation, and fast load shedding (FLS)

- IEC 61850 configuration

- Test procedures

Engineering Services

Our engineering services team provides a wide range of capabilities to assist you with your power protection, substation automation, and monitoring and diagnostics challenges.

We provide end-to-end solutions to support your project needs. From new installations to understanding the best way to upgrade an existing system, our engineering team has been trusted to analyze, design, and implement modern power systems with a broad range of engineering services that includes:

- Assuring proper logic design and IED configuration based on your specific project needs through our support on complex configurations like busbar engineering and automatic transfer schemes.

- Communication mapping on IEC 61850 MMS GOOSE, Modbus, Ethernet Global Data (EGD) or other protocols for smooth system integration.

- Uploading of configuration files prior to delivery to reduce work at destination through pre-load configuration.

- Confirming alignment between your project-specific requirements and protection system performance with our test procedures and factory acceptance testing (FAT).

Our range of Engineering services includes but is not limited to:

- Busbar engineering solutions

- Digital substation standardization

- IED configuration

- Protection schemes

- Automatic transfer schemes

- DER integration studies, dynamic line rating (DLR), distribution automation, and fast load shedding (FLS)

- IEC 61850 configuration

- Test procedures

Overview

IED configuration and pre-loading

These services entail configuration of Grid Automation and third-party P&C devices as per agreed settings and functionality.

Settings can be determined by our calculation of settings and studies or can be supplied by the customer.

Under request, the files can also be uploaded into the customer devices and tested before shipping or installation. Additionally, functional testing for final settings can be tested and reported.

Communication mapping

Communication capabilities of current relays are extensive and complex architecture networks are needed in existing substations.

Grid Automation experts can help to unleash communication capabilities within already installed devices, support customers in new deployments, or improve communications architecture and ensure efficient use of network traffic.

Our support can be as simple as helping to configure customer signal mappings, or complex IEC 61850 device integrations. Any protocol supported by our products can be managed.

FAT

The Grid Automation business offers the technical expertise to provide a reliable factory acceptance test, no matter if it is be carried out on our premises, or at third-party installations.

Before material delivery, our FAT support ensures functionality, quality, and integrity with our comprehensive checking process, guaranteeing that the equipment performs as expected under the testable range of foreseeable conditions.

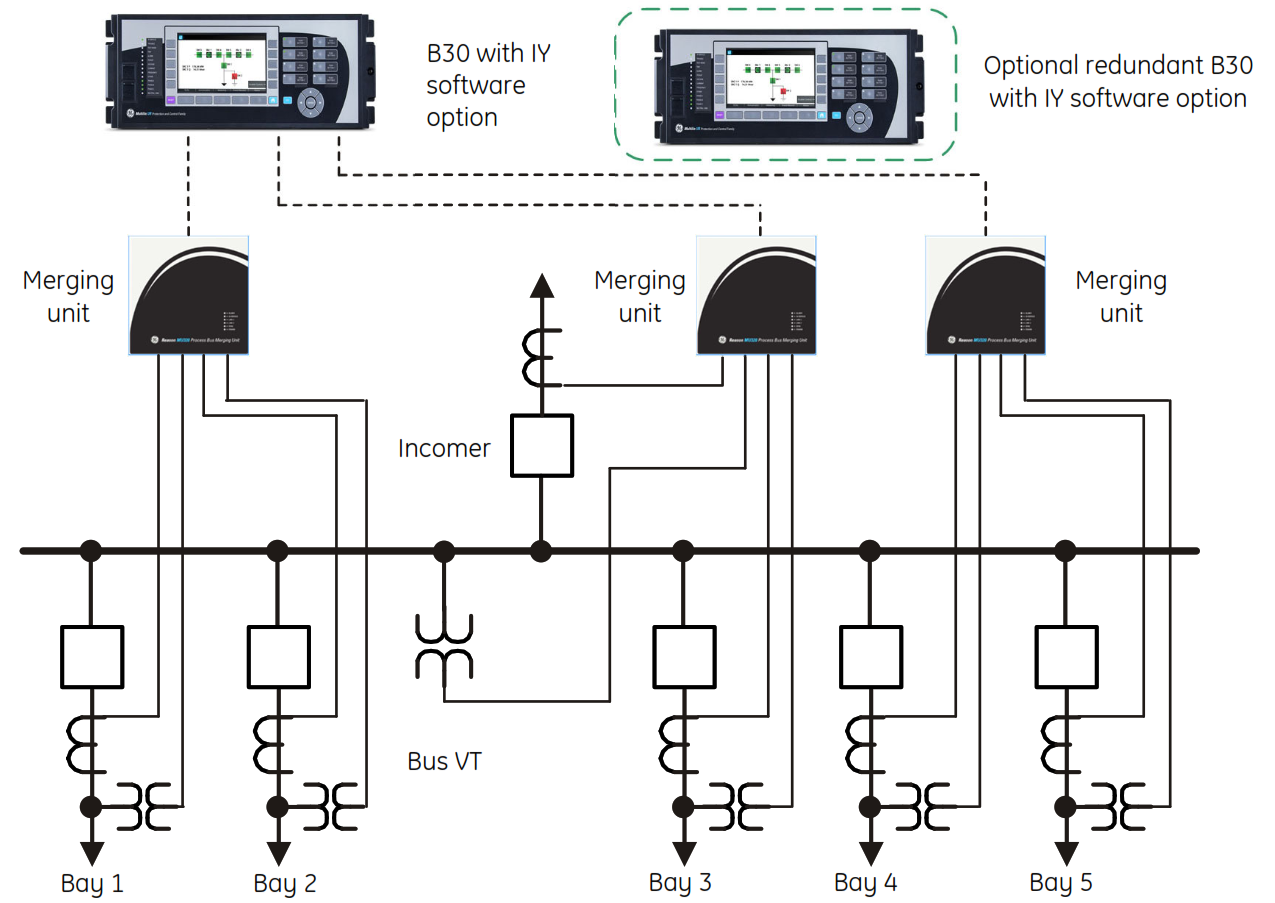

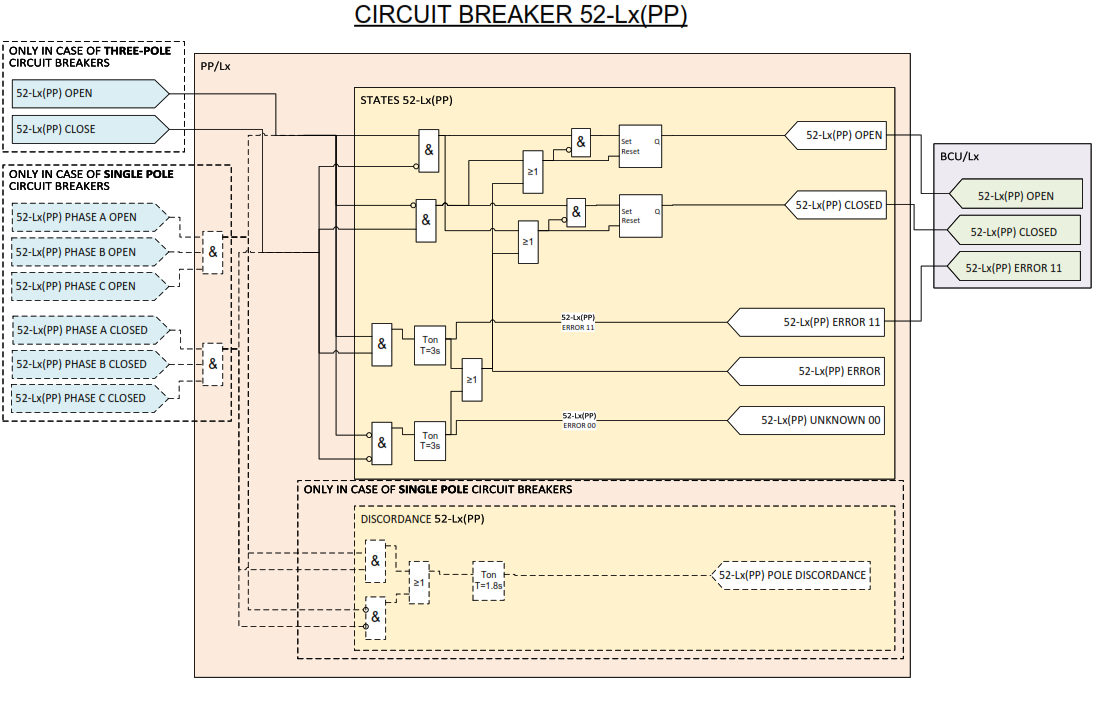

Busbar Engineering Solution

GE Vernova's Busbar Differential System provides fast and secure low impedance bus protection for reconfigurable LV, HV, and EHV busbars. This integrated solution is comprised of engineering, design, assembly, wiring, testing, and commissioning support for protection, control, and automation applications.

Depending on the nature of the protection, we differentiate between three different types of busbar differential projects:

- Busbar Differential Low-Impedance Centralized Protection System (B30/B90/P746/P747)

- Busbar Differential Low-Impedance Distributed Protection System (B30/P741/2/3 Agile)

- Differential High-Impedance Protection Systems (P145/P14NB)

Distributed Busbar Protection

The B30, a member of the UR family, provides busbar protection for up to 16 feeders with six differential zones. Communication between the bay and central units is done using process bus (IEC 61850-9-2LE) or standard (IEC 61869) protocols, and offers a large, full color LCD display. It can also be used for centralized protection of MV substations requiring busbar, breaker fail, feeder phase/neutral/ground overcurrent, and under/overvoltage protection.

Centralized Busbar Protection

Comprehensive and scalable bus and breaker fail protection for LV, HV, and EHV busbars. The B90, a member of the UR family, supports multi-section busbars schemes of up to 24 feeders and six zones, and offers a large, full color LCD display.

Key Benefits

- High-speed differential protection algorithm for sub-cycle trip times of 0.75 power cycle with CT saturation detection with only 2ms of saturation-free current.

- Multiple ethernet ports for station and process bus with advanced IEC 61850 Ed. 1 and Ed. 2 certified implementation, complete settings via SCL files and highly flexible process bus support (IEC 61850-9-2LE or IEC 61850-9-2 hard fiber) ensures interoperability, improved device management, and reduced cost of ownership.

- Routable GOOSE (R-GOOSE) enables GOOSE messages going beyond the substation.

- Application flexibility with multiple I/O options including high density I/O, programmable logic, modularity, and specific customization.

- Advanced cybersecurity features (CyberSentryTM) that help meet modern industry requirements.

- An integrated large, full color display provides real-time visualization and control of the protected bay via a bay mimic, as well as annunciator functionality and graphical visualization of phasors.

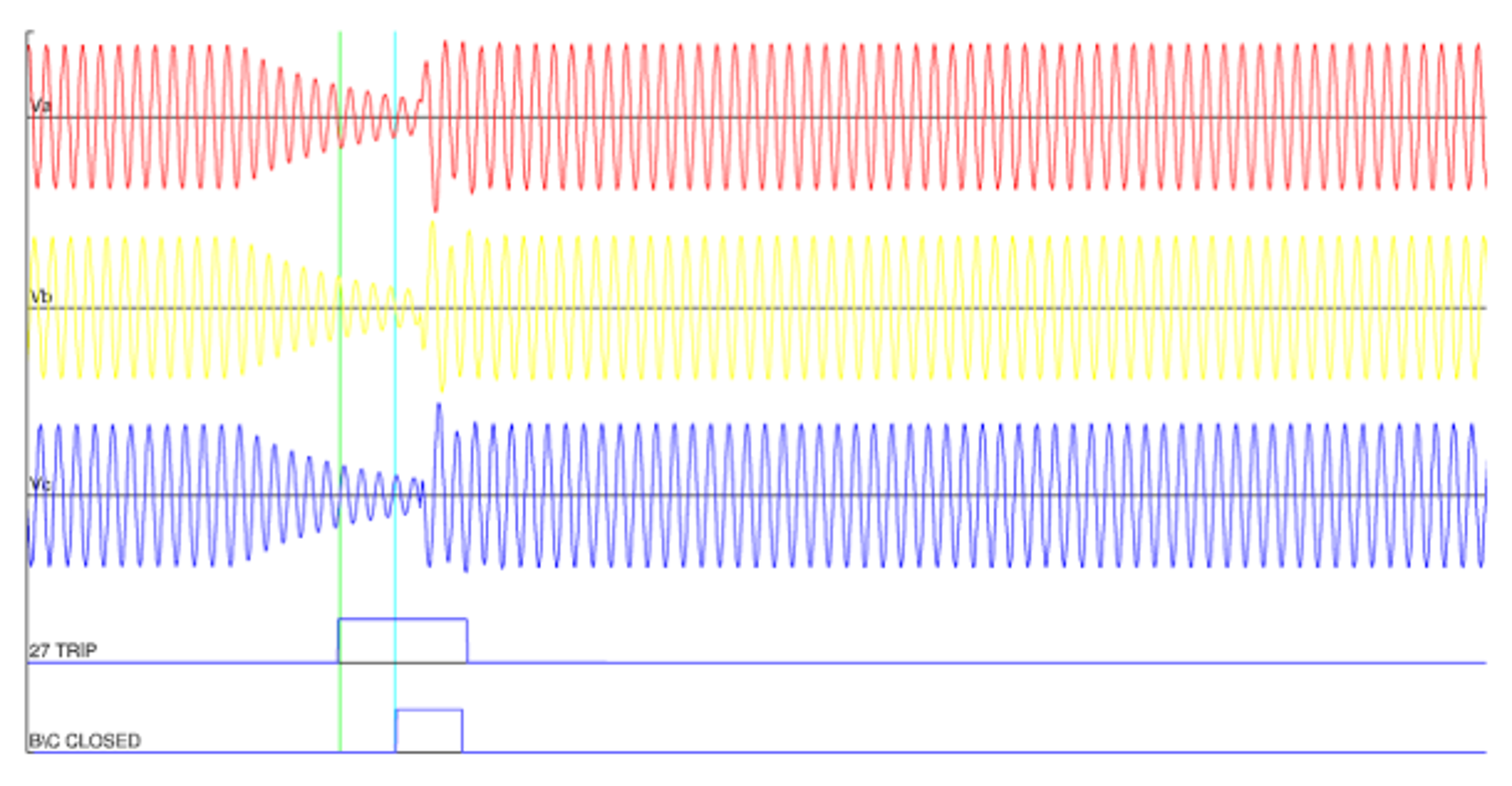

Automatic Transfer Schemes

Electrical processes are becoming more critical every day. Whether these processes are industrial or commercial, uninterrupted power supply is vital. In order to provide more reliable power supply, the power system can alternate sources to different bus bars. An Automatic Transfer Scheme (ATS) is the process of transferring the load of a busbar to another to ensure process continuity.

The ATS helps ensure the continuity of critical processes whose shutdown would result in unwanted economic and safety consequences. Transferring motor buses are specifically challenging due to the inertia forces and transients that exist in motors.

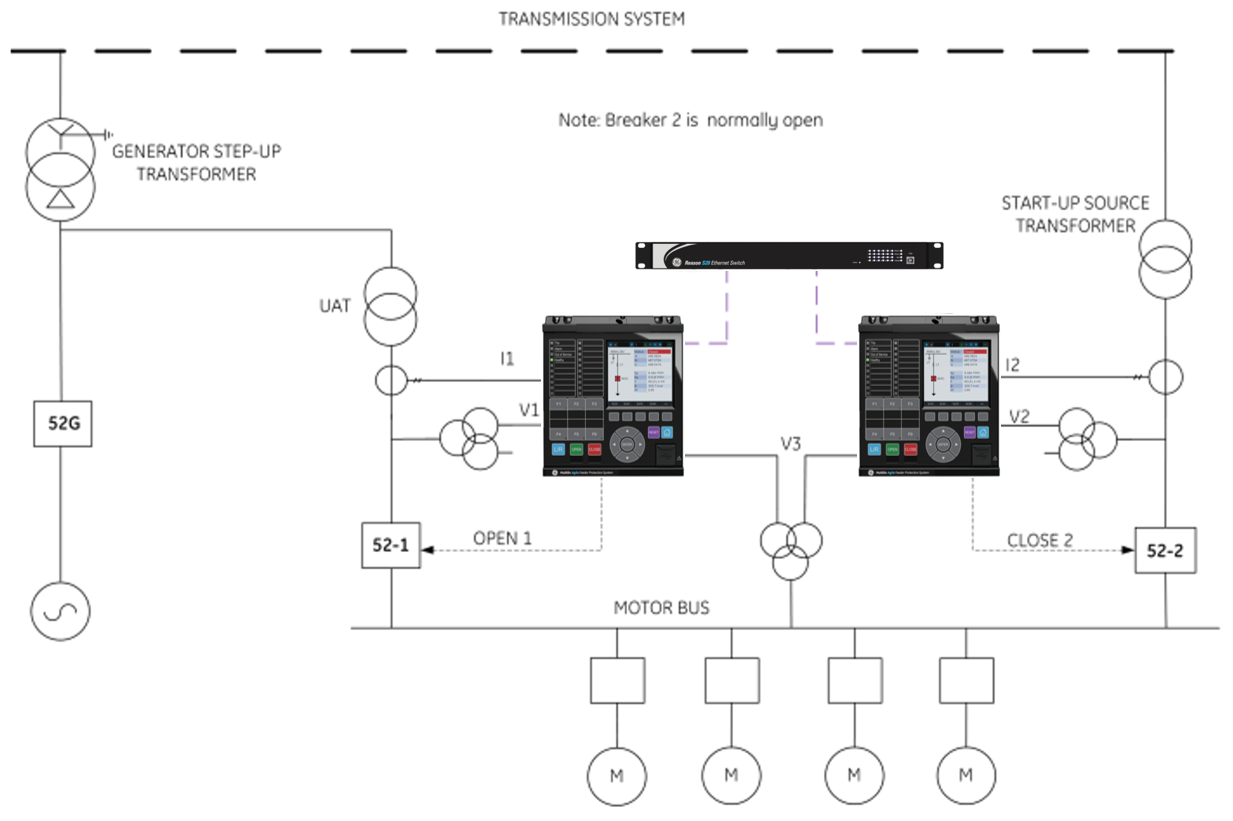

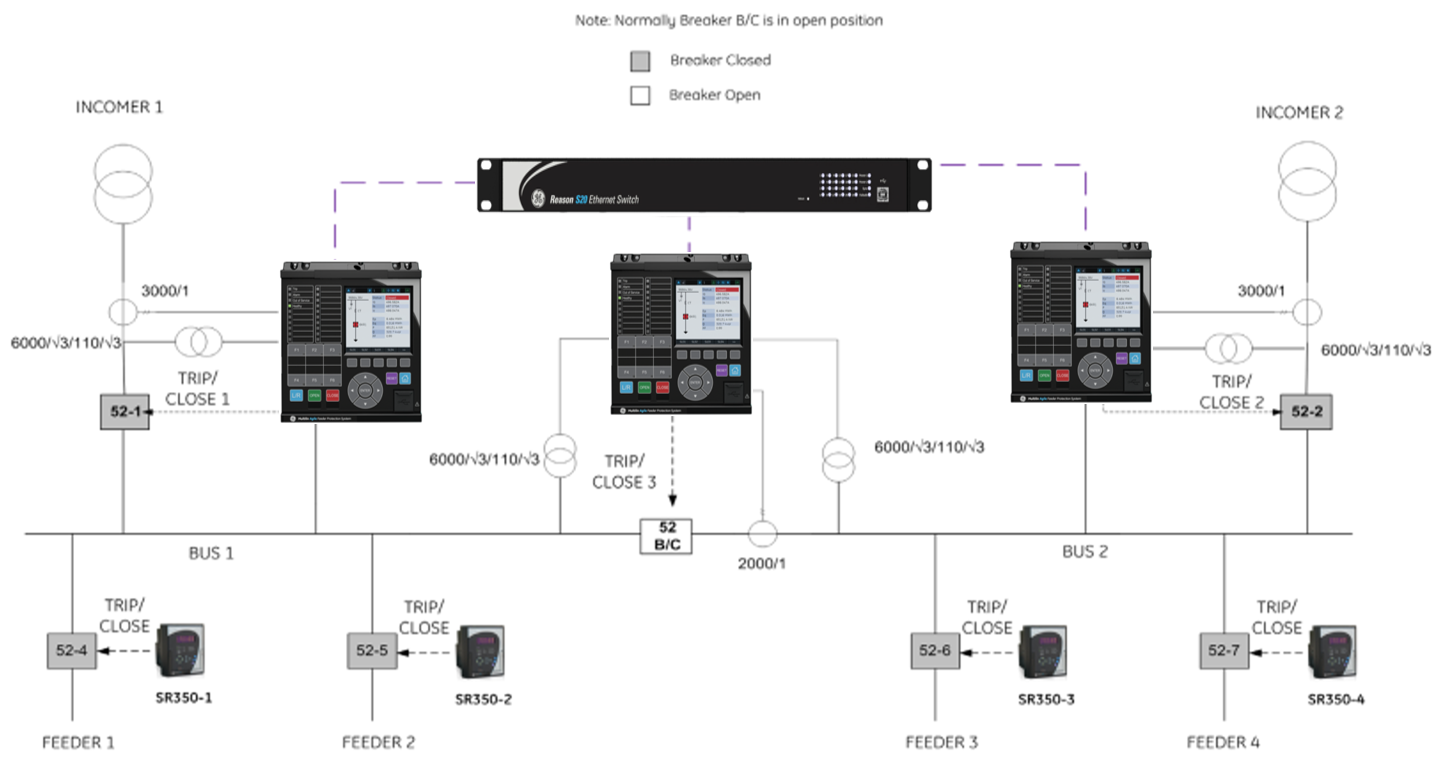

The Automatic Transfer and Restoration Scheme combines distributed protection, control, and ATS capabilities in a cost-effective package. Depending on your project-specific requirements for inputs/outputs, it can be performed on our SR850, F650, or P40x relays.

Key Benefits

- Control of multiple breakers

- Use of IEC61850 standard: reduction in cabling and commissioning costs

- Interlocking can be programmed in logic for a further reduction in costs

- Pre-built and/or custom logic

- Fast transfer, residual voltage transfer, or other customer-specific schemes

- Manual changeover can be implemented for planned start-ups, shutdowns, or changeover of power

- Make-before-break or break-before-make

- Automatic restoration with healthy voltage and synchrocheck criteria that minimizes the outage time and helps operators simplify the recovering process

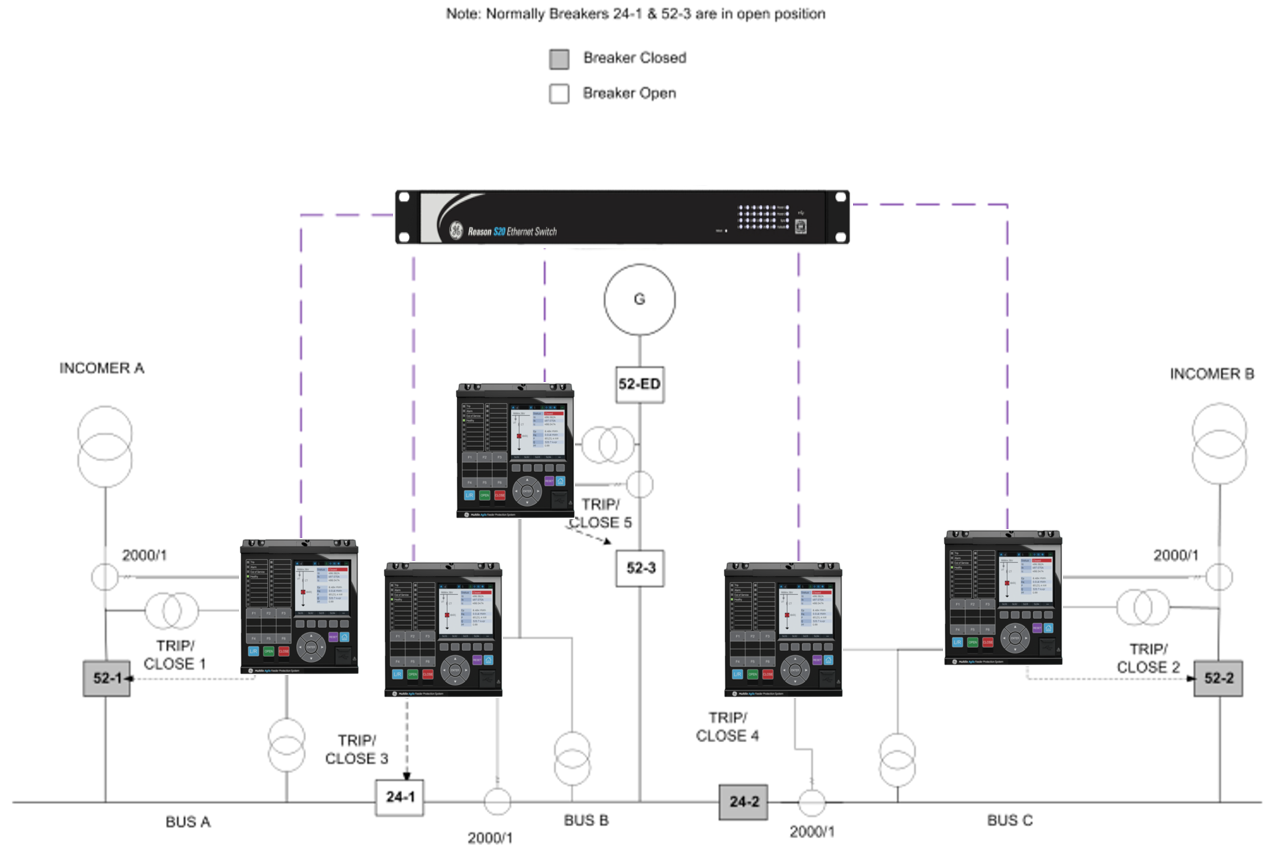

Main-Main

This configuration can be found in thermal power generating stations. The example shows a hard-wired solution.

Main-Tie-Main

This type of configuration is mainly used in industrial plants. The example shows a solution with GOOSE 61850 inter-relay communication.

Main-Tie-Main with Emergency Diesel Generator (EDG)

The Main-Tie-Main configuration can be improved by adding an emergency generator that would operate in case of loss of power on both main sources. The example shows a solution with GOOSE 61850 inter-relay communications.

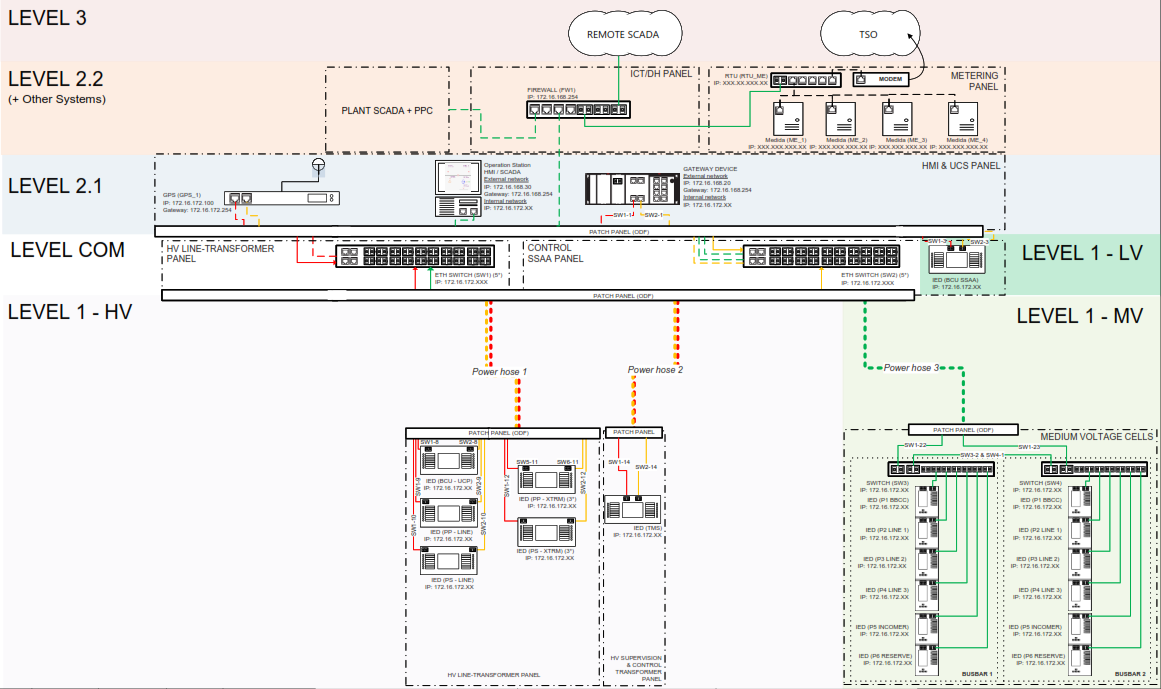

Digital Substation Standardization

The transition to digital substations has emerged as a transformative approach to enhance operational efficiency, flexibility, and reliability. Digital substation standardization is a critical process that defines consistent protocols, interfaces, and architectures for the seamless integration of intelligent electronic devices (IEDs), communication systems, and control infrastructure. Digital substation standardization is essential for driving the adoption and implementation of advanced technologies in power system networks.

Benefits

Our team possesses extensive expertise and experience in digital substation standardization, offering comprehensive solutions tailored to the unique needs of power system networks, including:

- A deep understanding of international standards and protocols relevant to digital substations, such as IEC 61850, IEEE 1588, and IEC 62351.

- Network architecture designed based on the substation architecture and topology for digital substations. We consider factors such as network topology, redundancy requirements, scalability, and system performance. By leveraging standardized architecture, such as the process bus and station bus concepts, we ensure efficient data exchange, streamlined control, and seamless integration of devices and systems.

- Our team has proficiency in integrating and configuring IEDs from various vendors within digital substations. We ensure that devices adhere to standardized communication profiles, data models, and protocols, enabling seamless interoperability and reliable data exchange.

- We prioritize cybersecurity in digital substations, implementing standardized security mechanisms, including authentication and access control.

- Test procedures for FAT, Site Acceptance Tests (SAT) and maintenance are provided based on IEC61850 standard, including simulation and test modes.

Use Case

Challenge: Assure a new standard for digital substation design and provide new communications networks and architecture on digital substations.

Value Added Proposition: Design and implementation of standardized schematics for network architecture and communication signals exchange. .scd and .cid template file generation.

Benefits: A standardized solution for three typical topologies, making them more efficient on digital substation implementation. Closure of technology gap for customer employees.

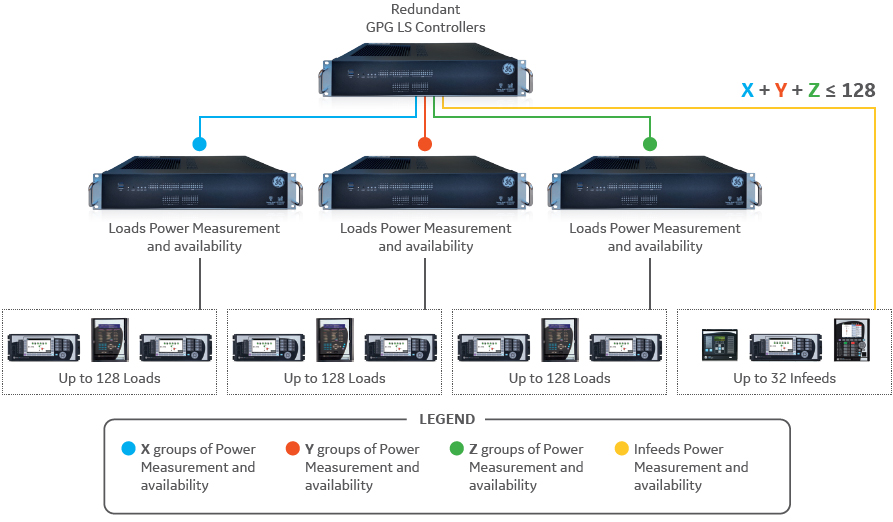

Remedial Action Schemes

Remedial Action Schemes (RAS) are a type of Wide-Area Protection Scheme, also known as Special Protection System (SPS) or System Integrity Protection Scheme (SIPS). RAS systems can detect disturbances in one part of an interconnected network that could result in interconnection overloading, under/over frequency conditions, and under/ overvoltage scenarios, and remediates these situations using pre-defined protection and control actions.

We support customers with the following services:

- Design and implementation of SIPS

- Defining RAS requirements

- System stability studies to identify contingencies and remedial actions

- Technical solutions and communication system architecture

- Solution validation including acceptance testing via advanced testing and result analysis

- Automatic data collection and results analysis from Grid Automation business and third-party devices

- System integration of the RAS system components

- Support during the commissioning of RAS components

Key Benefits

- Automatically disconnect generators or the load in the event of an unexpected loss of service of a transmission line to prevent system overloads.

- Improve system reliability by preventing power system outages.

- Increase transmission capability when building a new transmission line is not possible.

- Meet system operator mandates or system requirements.